Trunk whitewashing machine

A tree trunk and white machine technology, which is used in spraying devices, liquid spraying devices, gardening, etc., can solve the problems of insufficient pressure in the later stage, insufficient pressure in the early stage, low rotation accuracy, etc., to reduce the length requirement, improve the lifting efficiency, and has a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the accompanying drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

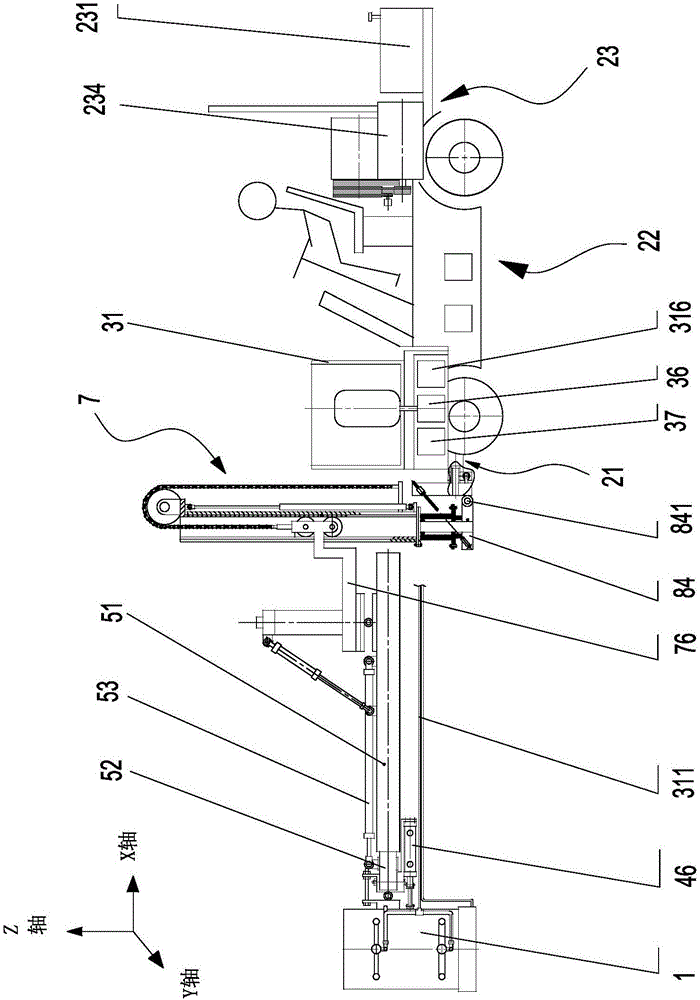

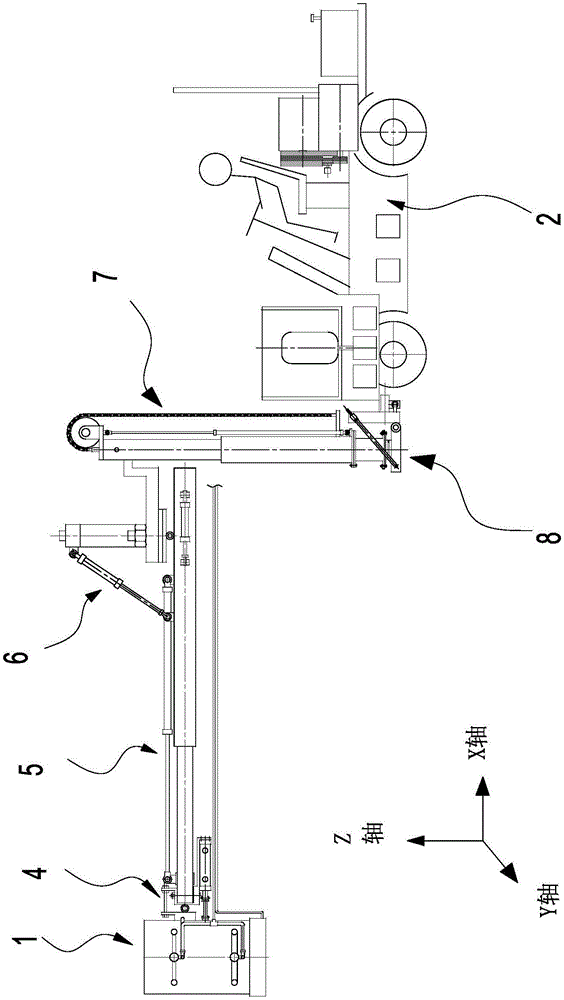

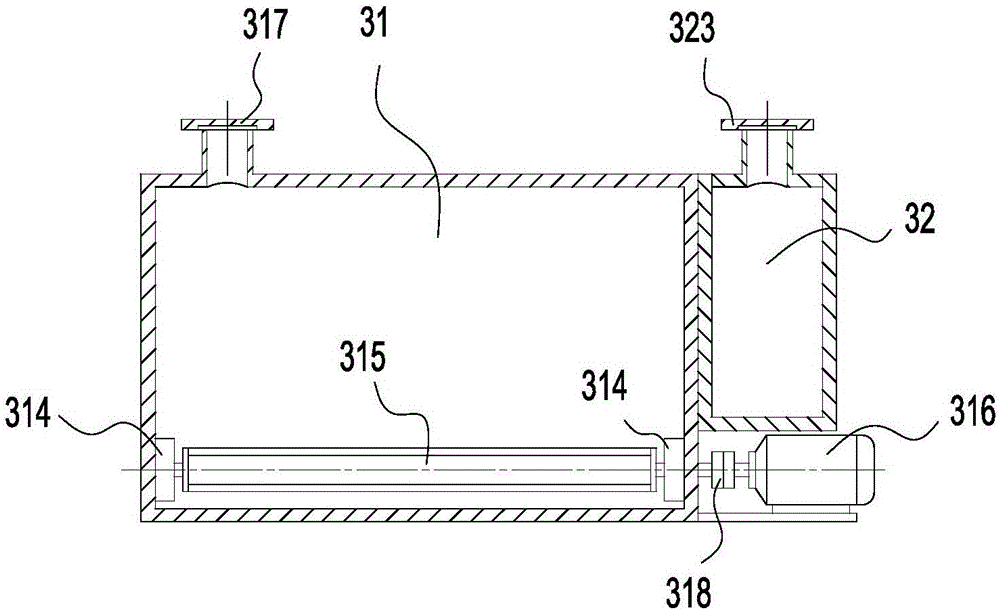

[0070] Such as figure 1 with figure 2 As shown, the present embodiment is a tree trunk whitening machine, including a motor vehicle, the front of the motor vehicle is provided with a working arm, and the front end of the working arm is provided with a spray barrel assembly 1, and the spray barrel assembly 1 includes a The left half barrel 11 and the right half barrel 12, the spray barrel assembly 1 is provided with a spray head 102, the left half barrel 11 and the right half b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com