Assembly box for transportation

A technology for assembling boxes and frames, used in transportation and packaging, packaging, container decorations, etc., can solve problems such as cracking, difficult-to-assemble box tracking management, first-in-first-out management, and assembly box distortion, to prevent damage and pollution, and to facilitate The effect of tracking management and thickness minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

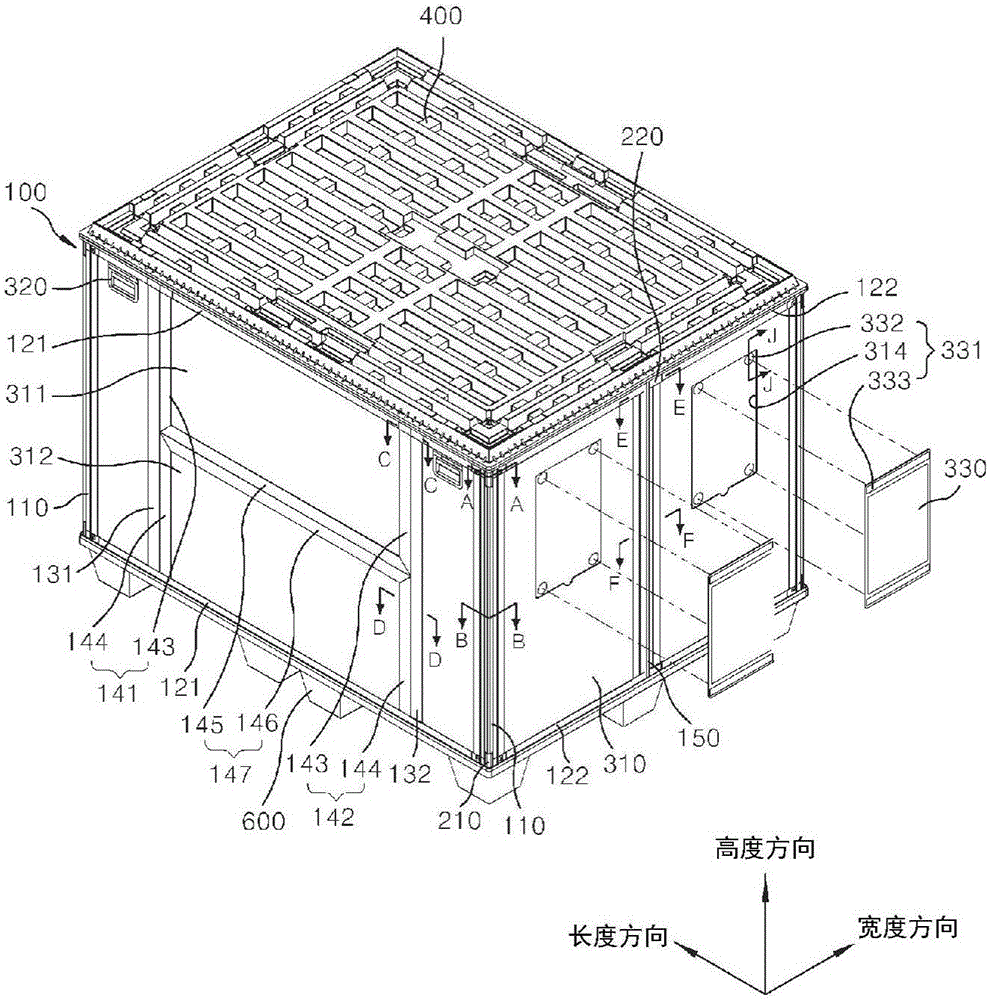

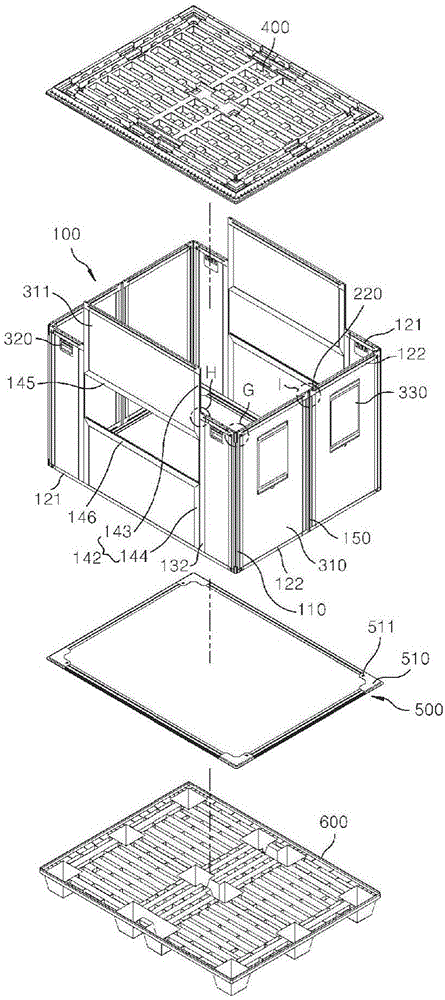

[0061] figure 1 To show a perspective view of a transport assembly box according to an embodiment of the present invention, figure 2 It is an exploded perspective view showing an assembly box for transportation according to an embodiment of the present invention.

[0062] Such as Figure 1 to Figure 2 As shown, the transport assembly box of the embodiment of the present invention may include: a body 100 including side walls, a frame (frame) and a bracket (bracket); a cover 400 for covering the upper end of the body 100; a base (base) 500, A bottom for constituting the main body 100 ; and a pallet (pallet) 600 .

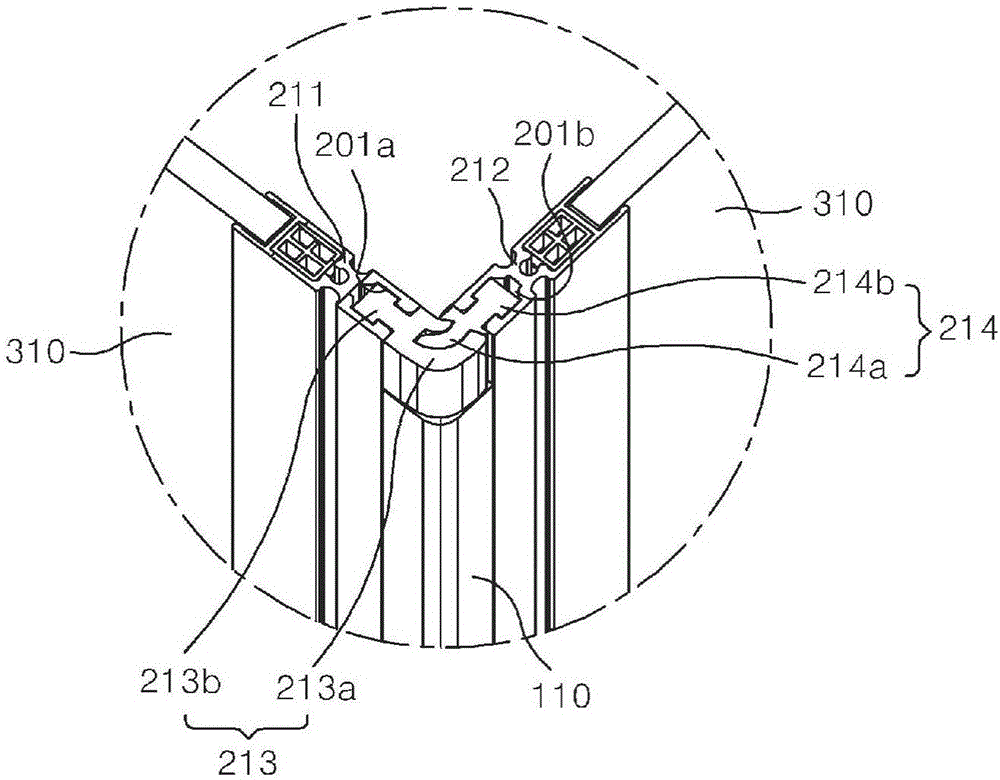

[0063] Specifically, the side walls 310 of the body 100 may be made of lightweight synthetic resin having excellent workability, for example, can be composed of plastic plates, and the side walls 310 may be assembled between frames. Wherein, the frame may include a vertical corner frame 110, a first horizontal frame 121, a second horizontal frame 122, a first ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com