Mould comprising mobile elements which are obtained by sintering

A technology for molds and molding components, applied in the field of movable components, can solve problems such as complex assembly, and achieve the effect of promoting demoulding and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

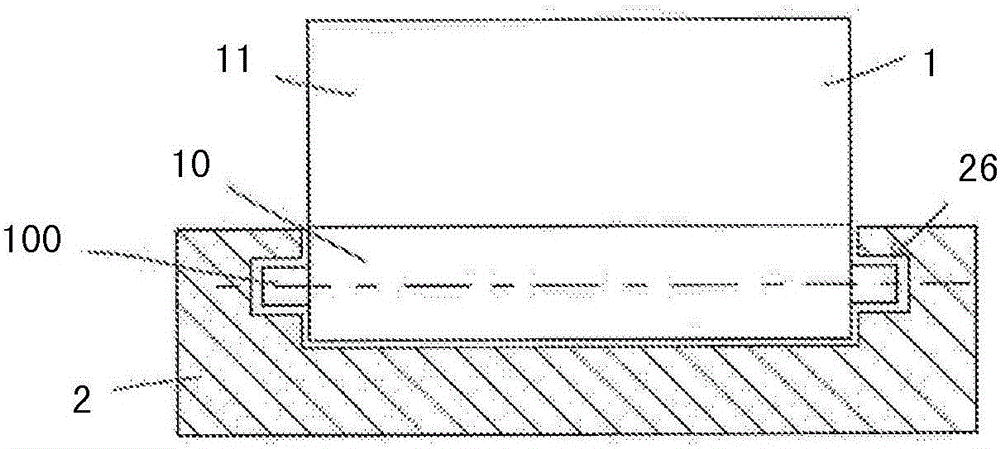

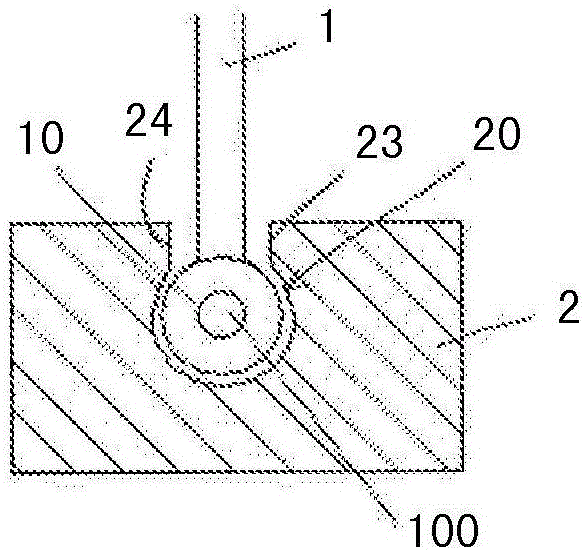

[0036] figure 1 and figure 2 The example shown in shows a liner comprising an articulated molded element 1 and a liner body 2 through which a cylindrical hole 20 passes. The molding element 1 comprises a molding part 11 , which in this case is a rectilinear part starting from the cylindrical part 10 , and a cylindrical part 10 arranged in a cylindrical hole 20 . The cylindrical part 10 rotates around the axis X and has on each side a cylindrical spigot 100 acting as a hinge, each cooperating with an orifice 26 extending the cylindrical hole 20 .

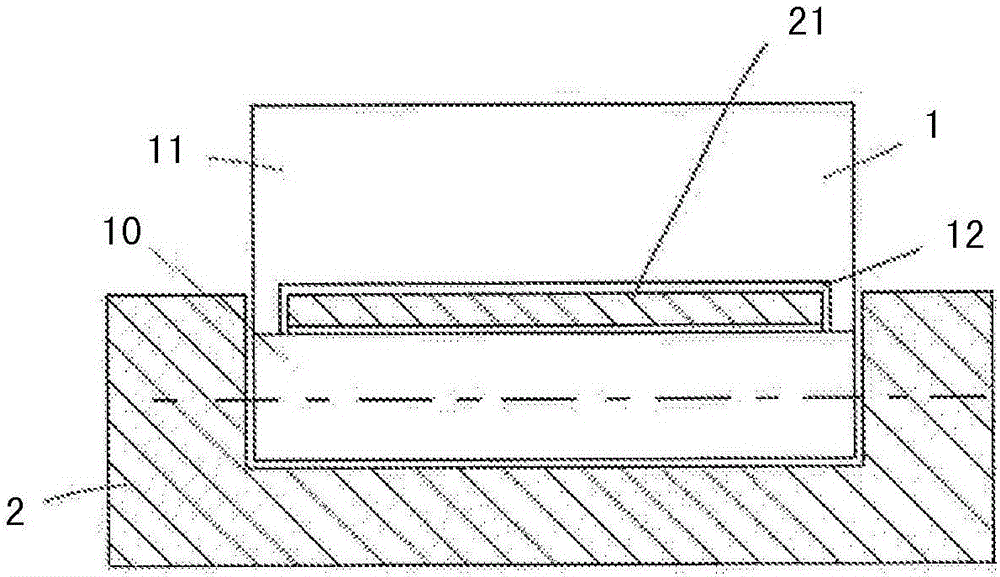

[0037] image 3 and Figure 4 The example shown in FIG. 1 shows a hinged molded element in which the molded part 11 has a notch 12 in which the peripheral part 21 of the liner body 2 can slide.

[0038] exist Figure 5 In the example shown, the molding element 1 has a cylindrical portion 10 pierced with a hole 101 into which a rod 22 with axis X is inserted and fixed to the inner liner 2 .

[0039] exist Image 6, the linear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com