Electric lead connecting fitting

A power wire and hardware technology, applied in the direction of conductive connection, electrical component connection, circuit, etc., can solve the problems of separation of two wires, easy to step on the connection point, and high safety of the wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

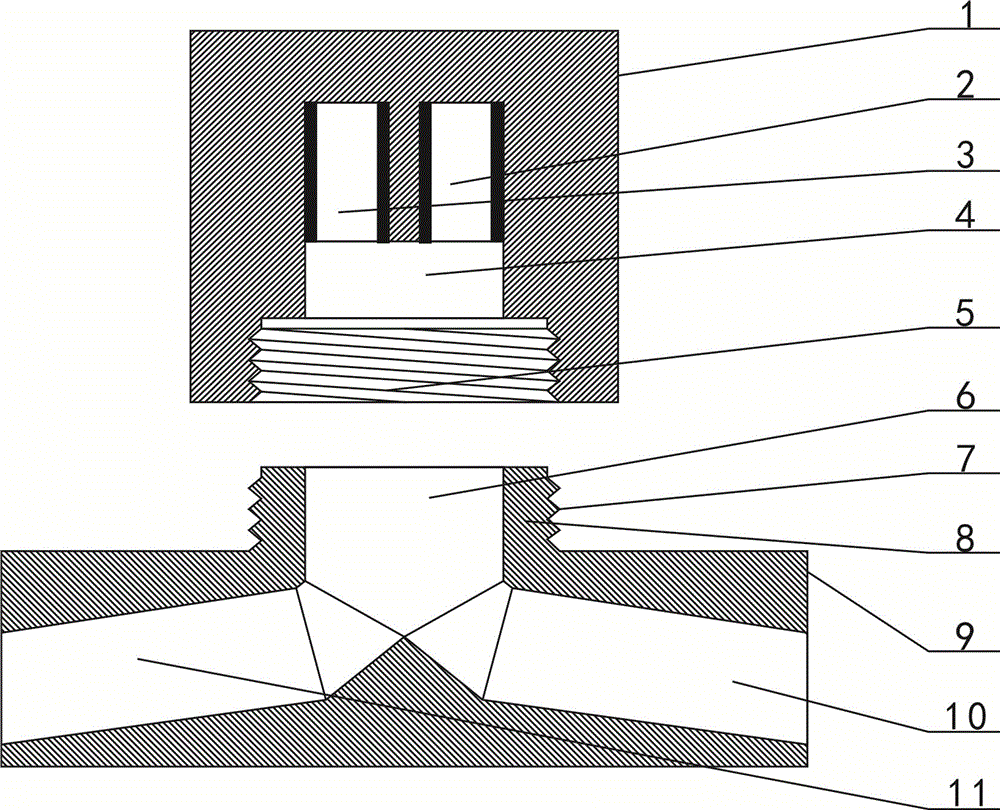

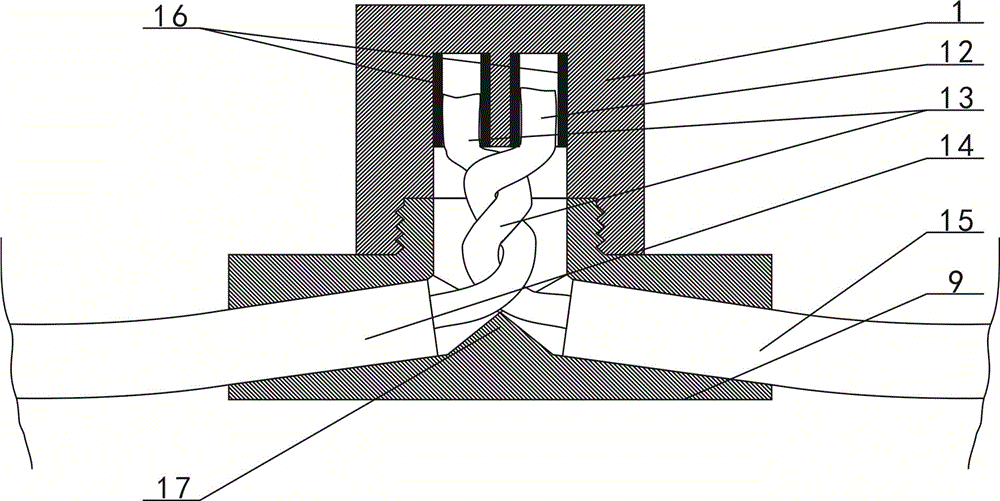

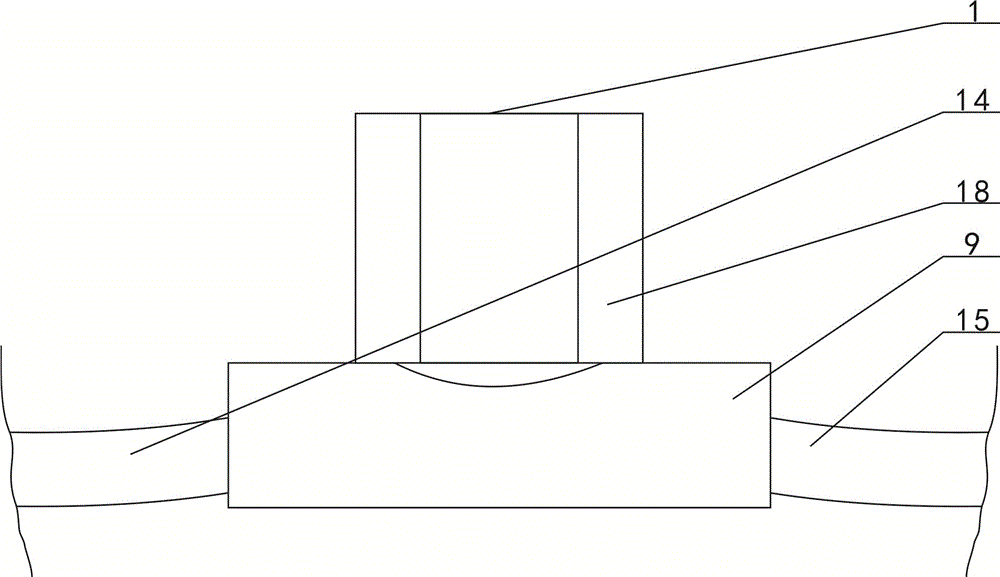

[0024] combined with Figure 1~3 The power wire connection fittings include a threading pipe 9, a connecting cover 1 and a fittings pipe 16, the middle part of the upper surface of the threading pipe 9 is provided with a raised standpipe 8, and the standpipe 8 is provided with a vertical hole 6, One end perforation 10 and the other end perforation 11 are respectively provided at the two ends of the threading pipe 9 to the middle vertical hole 6, and the one end perforation 10 and the other end perforation 11 are oblique holes high at the lower middle vertical hole 6 at the outer end. The inner wall of the hole 10 at one end is an interference fit with the outer skin of the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com