Relay

A technology of relays and contacts, which is applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of no ceramic cover structure, high cost, and poor arc extinguishing effect of high-voltage DC relays, etc., to reduce production costs, The effect of short production cycle and cheap equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

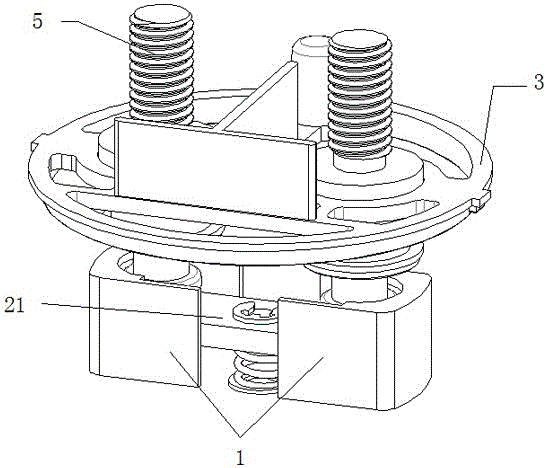

[0024] see Figure 1 to Figure 5 , the relay in this embodiment includes an upper gland 3, a contact chamber 4, a main contact 5, a movable contact assembly 2 and a ceramic cover 1 for protecting the contact chamber 4, and the upper gland 3 is arranged on the contact chamber 4 , the movable contact assembly 2 is fixed with the contact chamber 4, the main contact 5 is in contact with the movable contact assembly 2, the ceramic cover 1 is arranged in the contact chamber 4, and the movable contact assembly 2 includes a movable contact 21, an insulating support Seat 22, stainless steel connecting rod 23 and moving iron core 24, one end of stainless steel connecting rod 23 passes through insulating sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com