Calibrating device and method of vehicle profile dimension automatic measuring apparatus

A technology for automatic measurement of external dimensions, applied in the field of vehicle measurement, can solve the problems of no automatic measurement device for vehicle external dimensions, difficulty in ensuring measurement accuracy and stability, uneven product quality, etc., and achieve strong repeatability, Simple installation and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

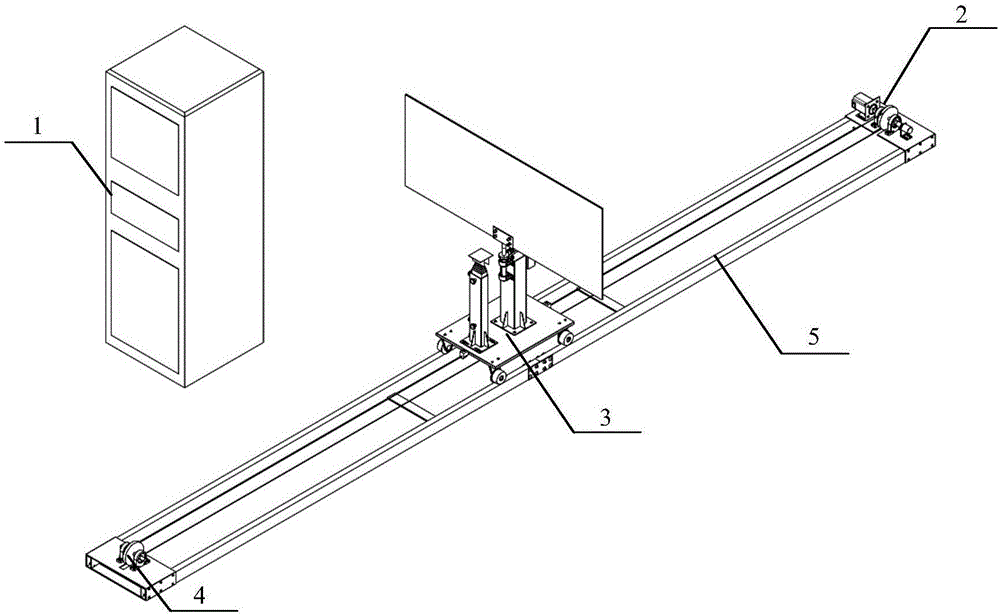

[0044] The specific content of the present invention and its implementation will be further described in detail below in conjunction with the implementation shown in the accompanying drawings.

[0045] The invention relates to a calibration device for an automatic measuring device for vehicle outline dimensions. The device is mainly composed of a stepping motor I6 and a stepping motor II35 of the same type, a photoelectric shaft angle encoder 13 and an industrial control computer 1. The model selected for the stepper motor is 86BYGH250H, the current is 5.6A, the body length is 150mm, the shaft diameter is 8mm, the keyway is 3×25, and the motor torque is 12.5N m; the model of the photoelectric shaft angle encoder is A-LEC- D5-102.4BM-G8-30F, the working voltage is DC5-24V, the maximum mechanical speed is 5000 rpm, the electrical response frequency is 20K / s, and the comprehensive speed is 2000 rpm; the model of the industrial control computer mentioned is EVOC IPC -810E, CPU is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com