Coreless motor magnetic steel detection device

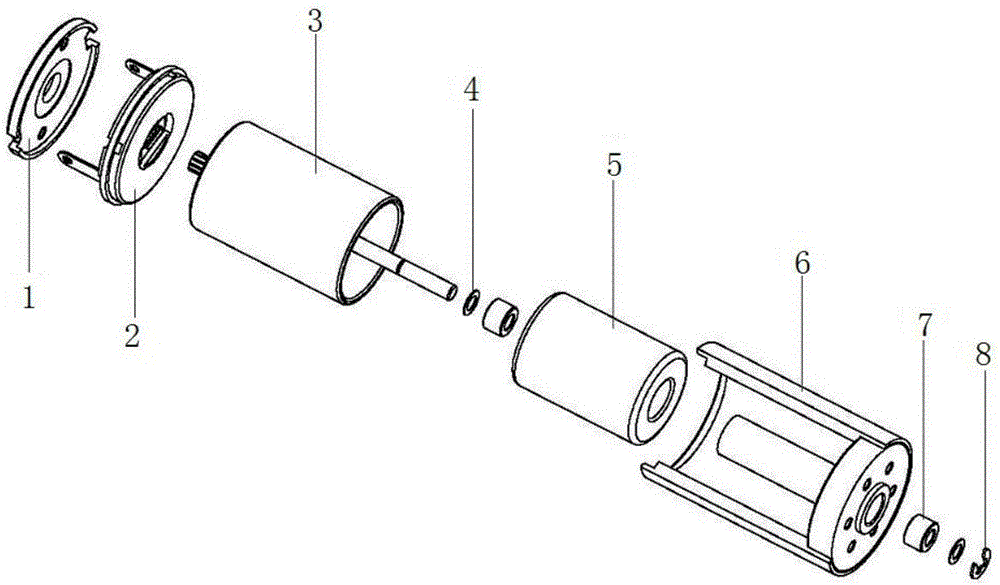

A detection device and a technology for a hollow cup are applied in the field of magnetic steel detection devices for hollow cup motors, and can solve problems such as the hazard of the yield of hollow cup motor products, the accurate detection of magnetic steel parts, and the existence of probability detection loopholes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

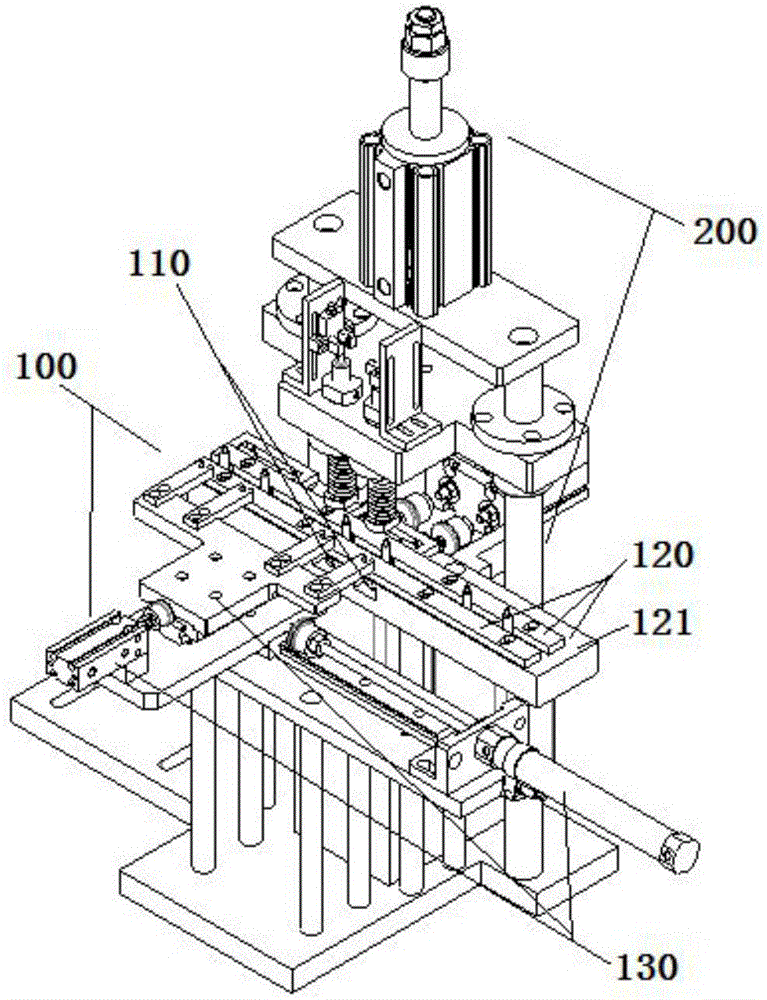

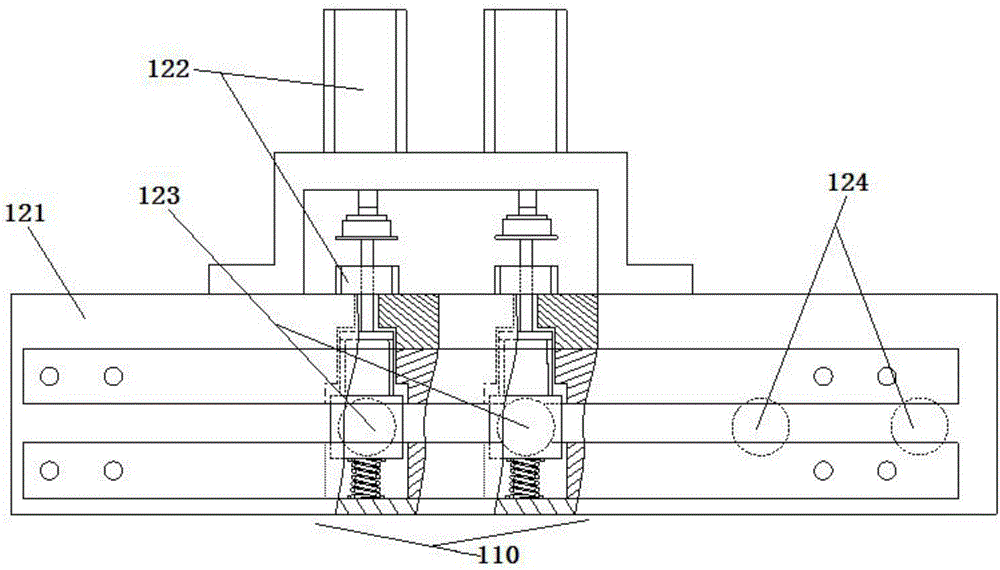

[0038] Such as Figure 2 to Figure 5 As shown, the present invention provides a coreless motor magnetic steel detection device, comprising: an automatic feeding device 100 and a motor magnetic steel assembly height identification device 200, the automatic feeding device 100 is provided with a detection station 110; The feeding device 100 includes: a track groove 120 and a material pushing device 130; figure 2 with image 3 As shown, the groove bottom plate 121 of the track groove 120 is provided with a plurality of first-type material blanking ports 123 containing a blanking control valve 122, and a plurality of hollowed-out second-type material blanking ports 124; The first type of material discharge port 123 is set at the position 110; Figure 4 As shown, the shifting device includes: a shifting disc 132 provided with two sets of shift forks 131, and a disc driving device 133 that drives the shifting disc 132 to move in translation on the same height plane as the track gr...

Embodiment 2

[0046] Image 6As shown, in this embodiment, on the basis of Embodiment 1, the motor magnetic steel assembly height identification device 200 includes: a pressing mechanism 210, an indenter mounting plate 220, a self-resetting indenter 230 and a position where a mounting bracket 241 is provided. The sensor 240; the installation frame 241 is tightly connected with the press head installation plate 230; the press-down mechanism 210 is fixedly arranged on one side of the automatic feeding device; the press head installation plate 220 is connected with the lower press head The action end 211 of the pressing mechanism 210 is tightly connected, and the pressing head mounting plate 220 has a degree of freedom of reciprocating movement along a direction perpendicular to the working plane of the automatic feeding device directly above the automatic feeding device; The head mounting plate 220 is fixedly provided with several self-resetting pressure heads 230 and the same number of posit...

Embodiment 3

[0051] Such as Figure 8 As shown, in this embodiment, on the basis of the above-mentioned technical solution, the blanking control valve 122 includes: a baffle plate 125 connected to a return spring at one end and a cylinder 126 for pushing the baffle plate to move; the baffle plate 125 includes a baffle plate Part Z and the blanking part L whose hollow area matches the cross-sectional shape of the magnetic steel shaft of the hollow cup motor. The other end of the shielding plate is fixedly provided with a push rod T; Said push rod T offsets.

[0052] The present invention helps to achieve the technical effect of controlling the opening and closing of the valve body through the action of the cylinder by adopting the blanking control valve provided with the baffle plate; wherein, the above-mentioned structure can preferably be made into a structural whole with the track groove, thereby eliminating the need for separate processing The production cost of the valve body of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com