Auxiliary explosion vibration tester and explosion vibration test method

An auxiliary equipment and vibration measurement technology, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the sensors of blasting vibration measuring instruments cannot be placed, the level of sensors cannot be guaranteed, and the connection strength is lacking. It is convenient and labor-saving, simple in structure and low in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

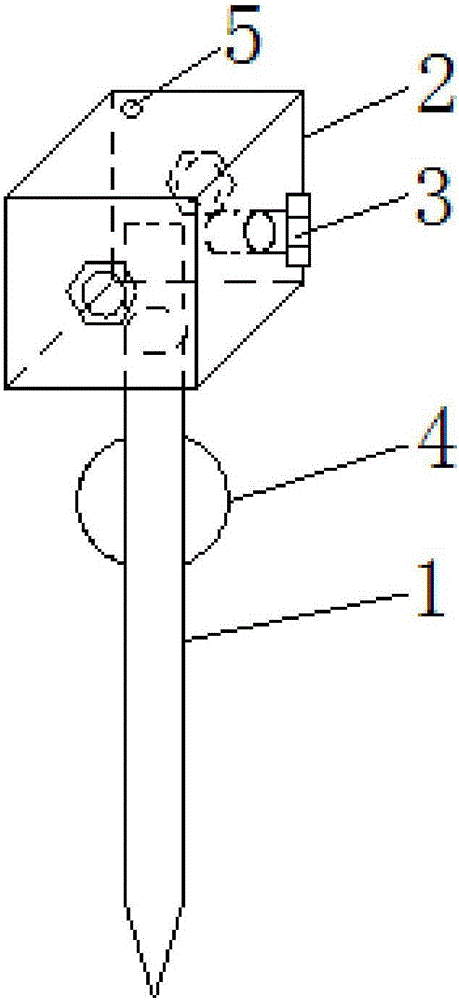

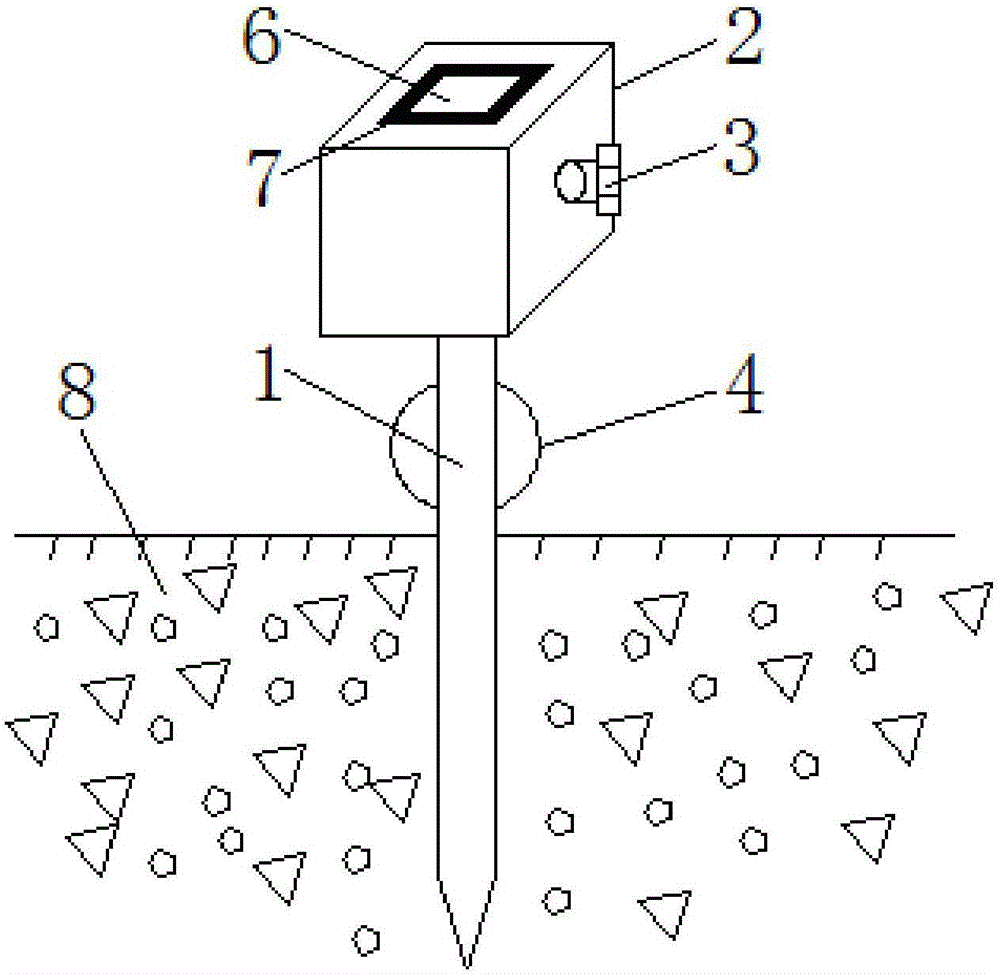

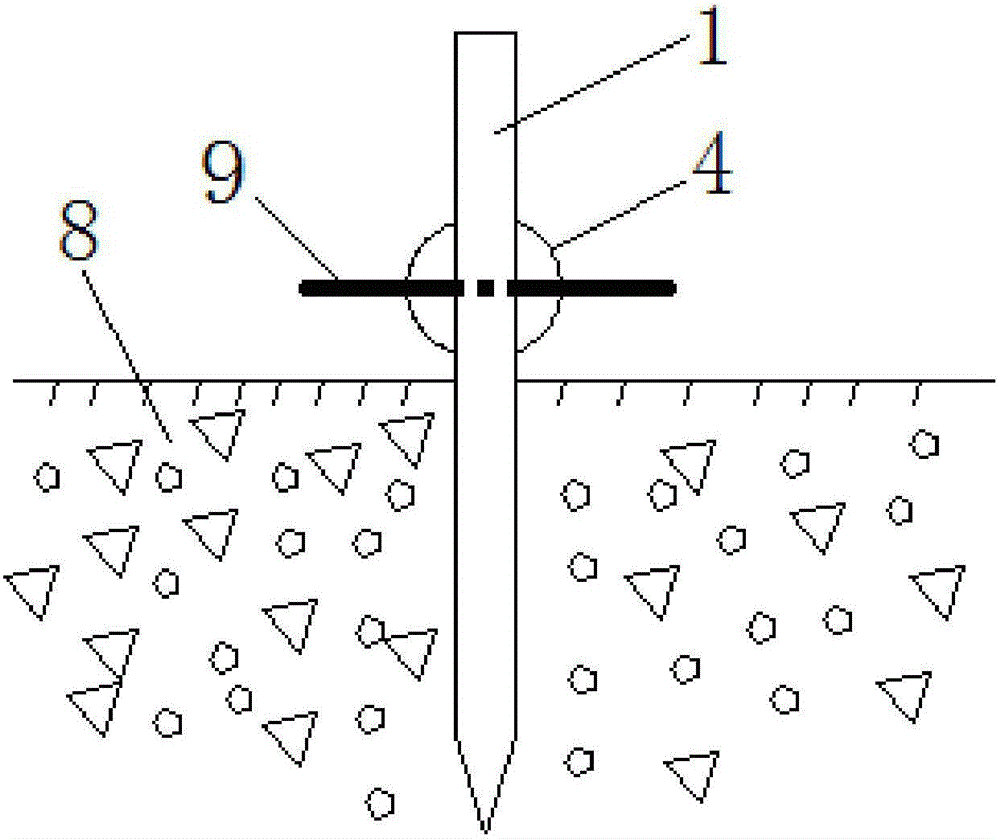

[0031] The invention provides an auxiliary equipment for blasting vibration measurement, the structure of which is as follows: figure 1 As shown, it includes a foundation pile 1 and the installation position of the vibration meter. The foundation pile 1 is a steel bar with a length of 25-30 cm and a diameter of 1-1.5 cm. The lower end of the steel bar is a cone with a taper of 1:1-1:3, so The installation position of the vibration meter is a hollow cube 2 with three adjustment screws 3, the hollow cube is a cube with a side length of 8cm, and the three adjustment screws 3 are respectively located on the three front sides, the rear side and the right side of the hollow cube 2. On the surface, the axes of the three adjusting screws 3 are located on the same horizontal pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com