A kind of measuring device and measuring method for full length straightness of steel pipeline

A measuring device and straightness technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of unsuitable steel pipe detection, and achieve the effect of easy automatic adjustment, time saving and accurate measuring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

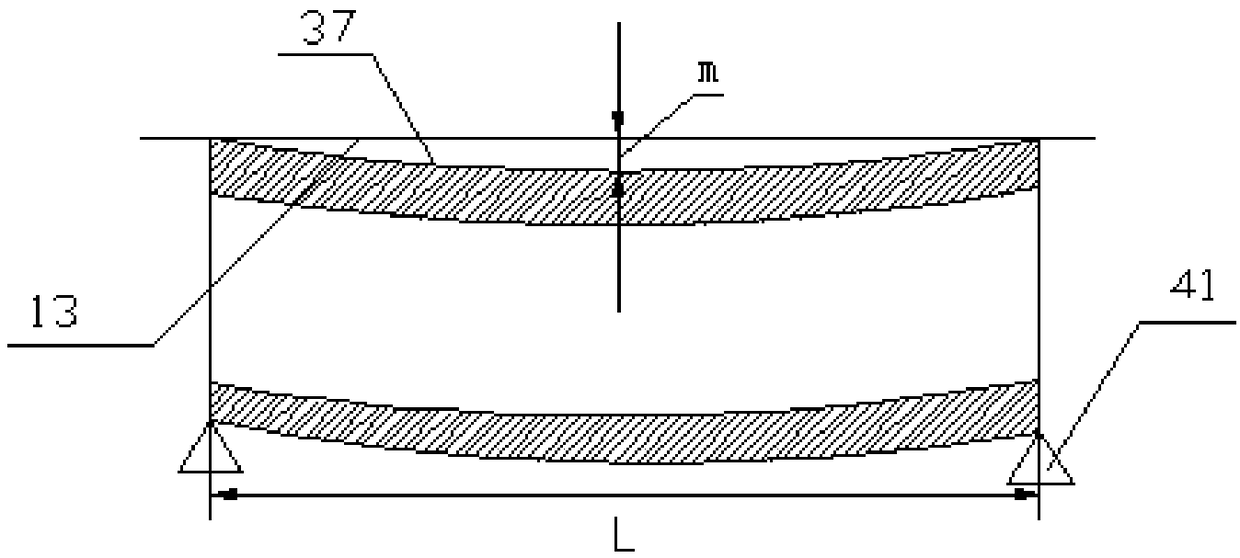

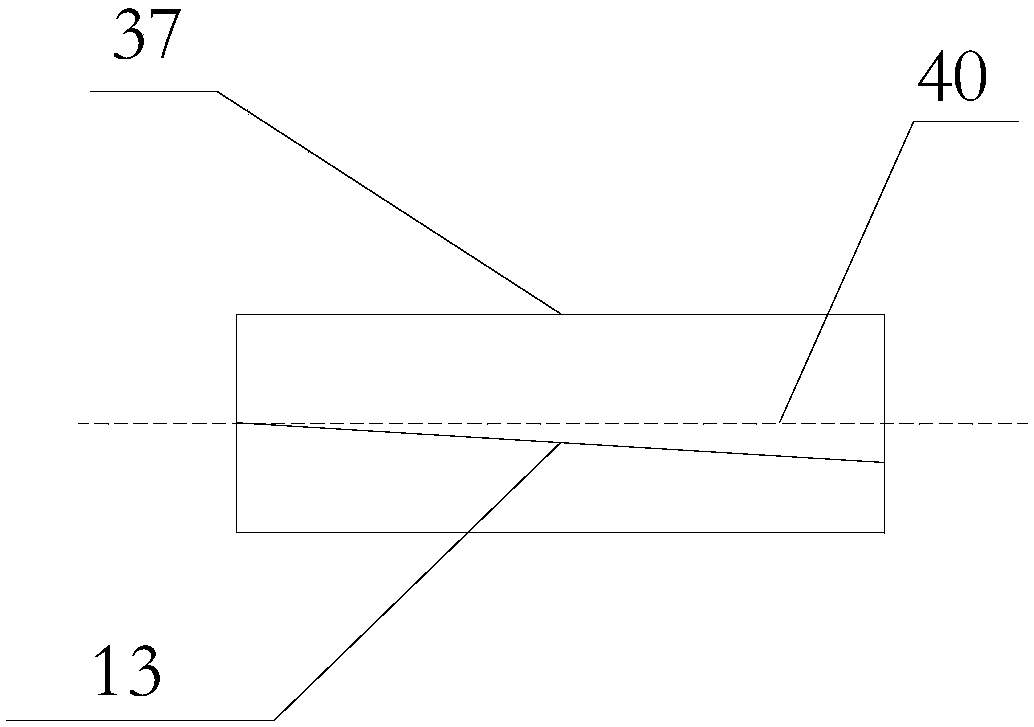

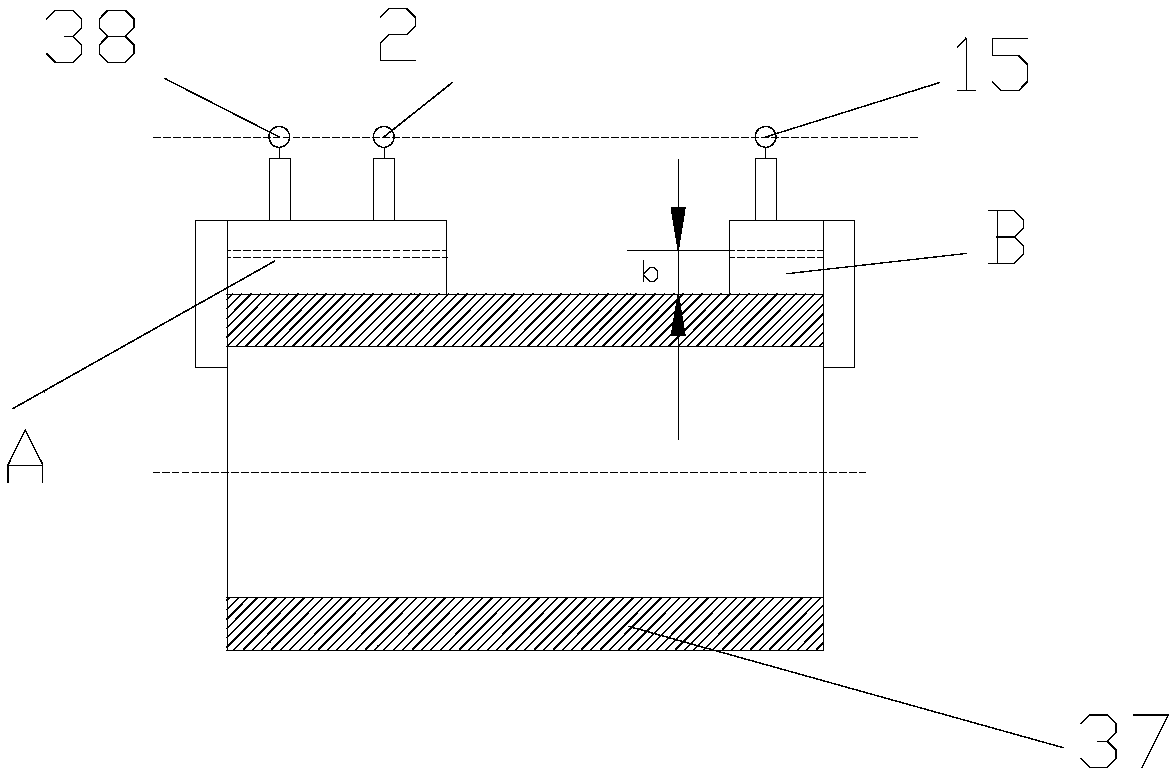

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] like Figures 1 to 8 As shown, in a measuring device for the straightness of a steel pipeline provided by the present invention, there are two rectangular chutes on the A-end longitudinal clamping plate 6, in which the first A-end is aligned with the slider 1 and the first A-end respectively. Two A end alignment sliders 3, the second A end alignment slider 3 and the first A end alignment slider 1 are respectively the second A segment alignment head 2 and the first A end alignment head 38, and the second A end alignment head 38. The side of the end alignment slider 3 is fixedly connected to the handle 4 of the A end slider, and the inner wall of the rectangular chute is in close contact with the alignment slider. When the alignment slider moves upward to the maximum stroke, the inner wall of the rectangular chute and the alignment slider The friction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com