Liquefied natural gas dispenser calibrating device and method

A technology of liquefied natural gas and verification devices, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as human injury, achieve the effects of preventing leakage, stabilizing data communication, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

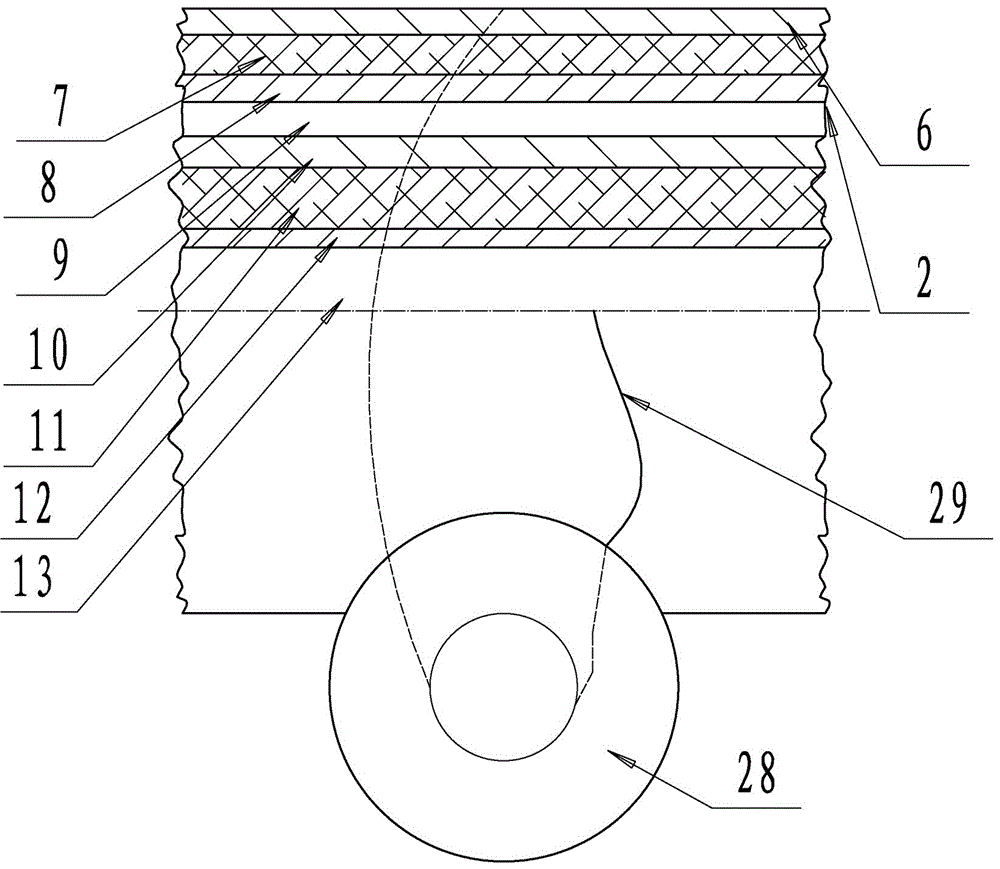

[0048] Such as Figure 1-6As shown, the present invention is used to verify the accuracy of the filling volume of the liquefied natural gas dispenser, including the insulation pipeline 2, the insulation pipeline 2 includes a hose connection transition pipeline 30, and the insulation pipeline 2 includes a hard pipe pipeline 31 or The heat preservation pipeline 2 includes a hard pipe pipeline 31 and a hose connection transition pipeline 30 connected with the hard pipe pipeline 31;

[0049] Insulation pipeline 2 specifically (hose connection transition pipeline 30, hard pipe pipeline 31 or hard pipe pipeline 31 and hose connection transition pipeline 30 connected to hard pipe pipeline 31) includes an outer wall layer and an outer wall layer The vent channel 13 inside and communicated with the gas filling gun 1 of the LNG filling machine is provided with a vacuum layer 9 in the outer wall layer.

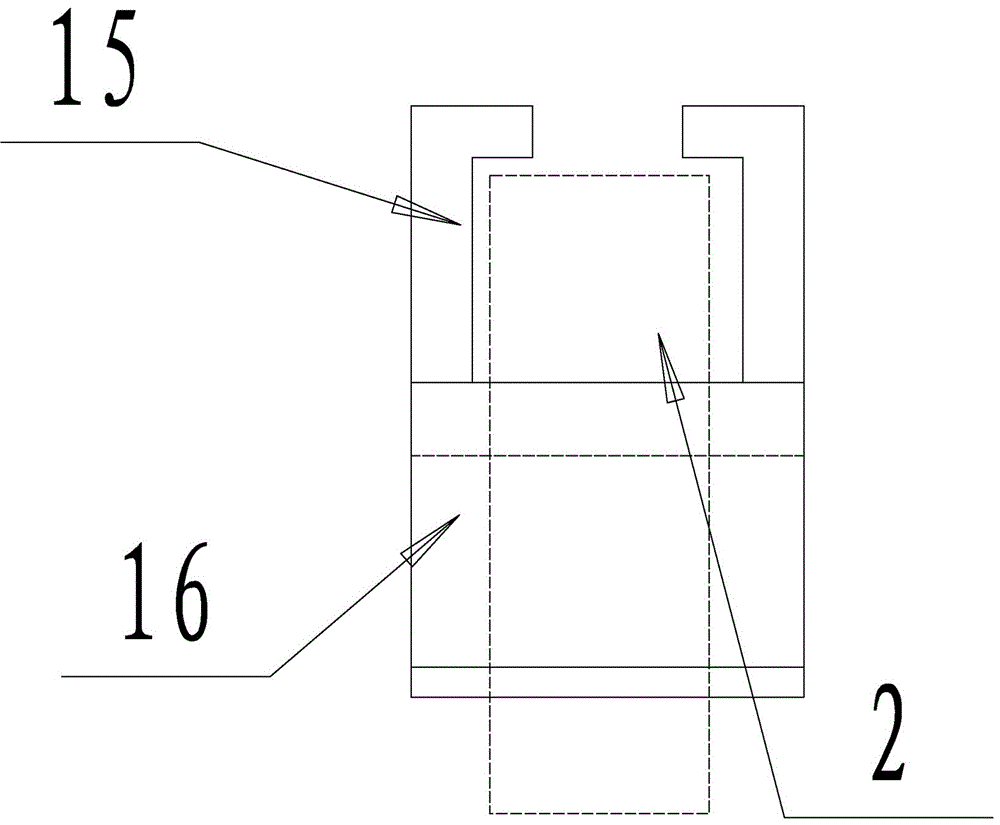

[0050] Such as image 3 As shown, in the hard pipe pipeline 31: between the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com