Testing device and method for flow of multistage axial-flow fan of turbine generator

A flow test device, the technology of the turbine generator, applied in the direction of engine function, machine/engine, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

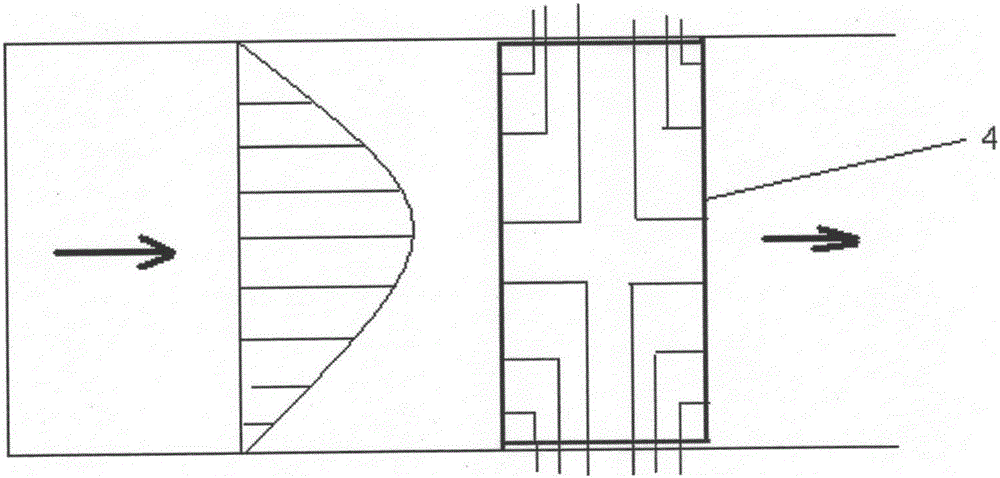

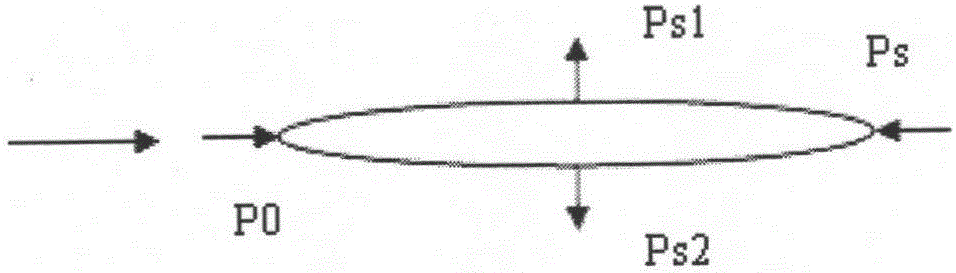

[0023] Such as figure 1 As shown, this embodiment provides a steam turbine generator multi-stage axial fan flow test device, which includes a main body 4 with the same shape as the fan blade to be tested. The front and rear edges of the main body 4 are symmetrically arranged There are five pairs of pressure measuring hole 1 and pressure measuring hole 2; the main body 4 has a pressure measuring hole 3 3 on both sides of the leaf surface, and the pressure measuring hole 3 3 is located at 1 / 2 of the height of the main body 4. Each pressure measuring hole is connected to the pressure measuring tube of the pressure measuring instrument through a respective measuring pipe in the main body 4.

[0024] A method for testing the flow rate of a multi-stage axial fan of a steam turbine generator: the above-mentioned multi-stage axial fan flow test device of the steam turbine generator is installed in parallel on one side of any blade of the fan to be tested, and the fan is turned on for test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com