Simulation experiment method of multi-layer commingling capacity of natural gas reservoir

A multi-layer co-production and simulation experiment technology, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems that the evaluation results cannot effectively guide the field development, and the distance is large, so as to achieve convenient operation and accurate gas Intuitive effect of production capacity and experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

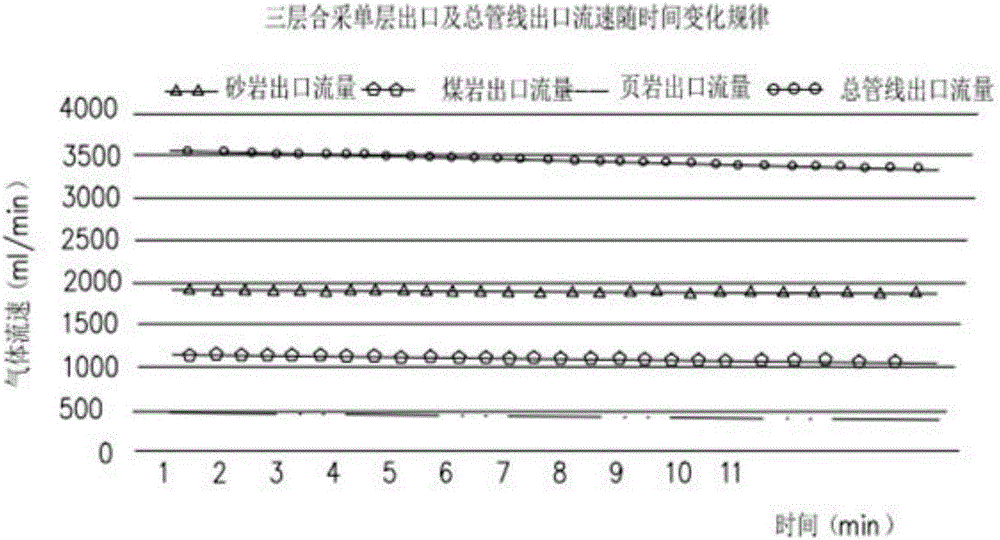

[0041] Joint development of production layer 1 and production layer 2

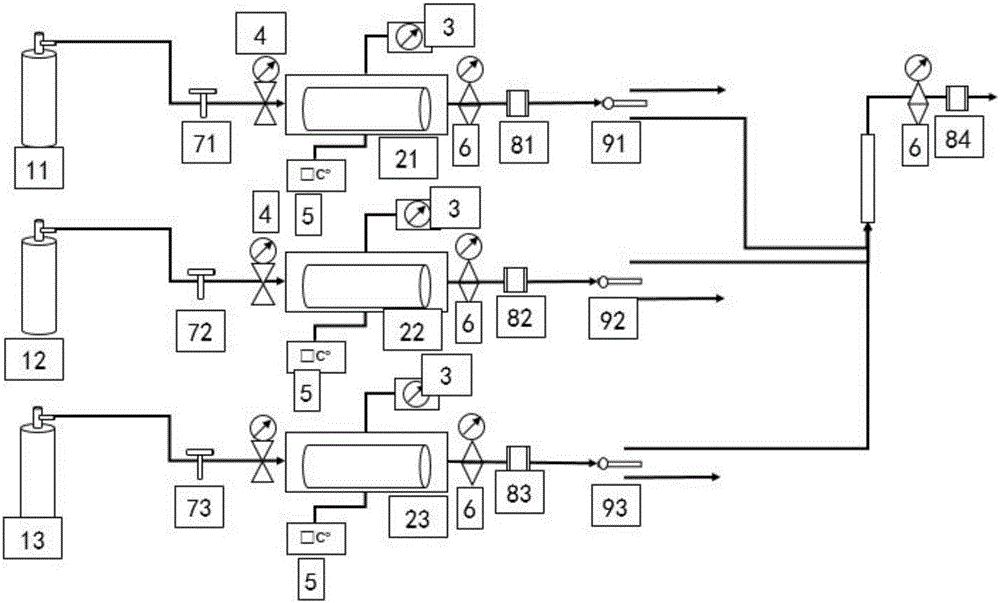

[0042] In order to simulate the above three production layers, it is necessary to use three pressure cylinders 1, such as figure 1 As shown, it is assumed that the numbers of the three pressure container gas cylinders 1 are respectively gas cylinder 11, gas cylinder 12 and gas cylinder 13, wherein gas cylinder 11 corresponds to formation serial number A, gas cylinder 12 corresponds to formation serial number B, and gas cylinder 13 corresponds to In Strata No. C.

[0043]The initial pressure of the gas cylinder 11 is set to 30 MPa, and the confining pressure of the core holder 21 connected to the gas cylinder 11 is 16 MPa. Put a core plunger with a diameter of 25 mm into the core holder 21, set the temperature of the core plunger to 46° C., and keep the air inlet pressure of the cylinder of the core holder 21 constant at 13 MPa.

[0044] The initial pressure of the gas cylinder 12 is set to 30MPa, and the...

Embodiment 2

[0053] (1) Determine the number of core plungers used in the indoor simulation experiment according to the number of strata in the joint mining.

[0054] (2) Put the core plunger used in the experiment into the corresponding core holder after the pre-cleaning, drying and vacuuming treatment.

[0055] (3) According to the measured data of the stratum on site, the temperature of the core plunger is controlled to be consistent with the formation temperature, and the confining pressure of the plunger is consistent with the stress of the overlying rock in the stratum. Control the inlet pressure of the core plunger to be consistent with the on-site formation pressure, and control the outlet pressure of the core plunger to be consistent with the pressure of the on-site gas production tubing.

[0056] (4) Connect the inlet of each core holder to a fixed-volume high-pressure gas cylinder, and fill the gas cylinder with nitrogen or air until the initial pressure value is greater than th...

Embodiment 3

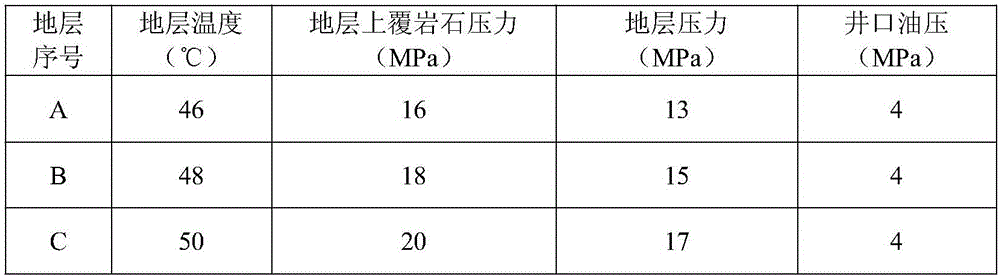

[0062] The stratigraphic parameters of the three production zones simulated by the evaluation device are shown in Table 3.

[0063] Table 3 Stratigraphic parameters of production zones

[0064]

[0065] Joint development of production layer A, production layer B, and production layer C

[0066] Take the multi-yield comprehensive development production capacity evaluation experimental device connected in parallel with three sets of single-yield development simulation devices as an example, as shown in the accompanying drawing figure 1 As shown, the joint development of production layer A, production layer B and production layer C is simulated.

[0067] Set the initial pressure of the gas cylinder 11 to 25MPa, and set the confining pressure of the core holder of the production layer A to 18MPa. A core plunger with a diameter of 25mm is loaded into the core holder 21, the plunger temperature is set at 48°C, the inlet pressure is constant at 16MPa, and the outlet pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com