Stepping type self-balancing derrick workover rig

A step-by-step, self-balancing technology, used in drilling equipment, earth-moving drilling, support devices, etc., can solve the problems of narrow space, small well spacing, affecting operation timeliness, etc., and achieve convenient movement, compact structure and high operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

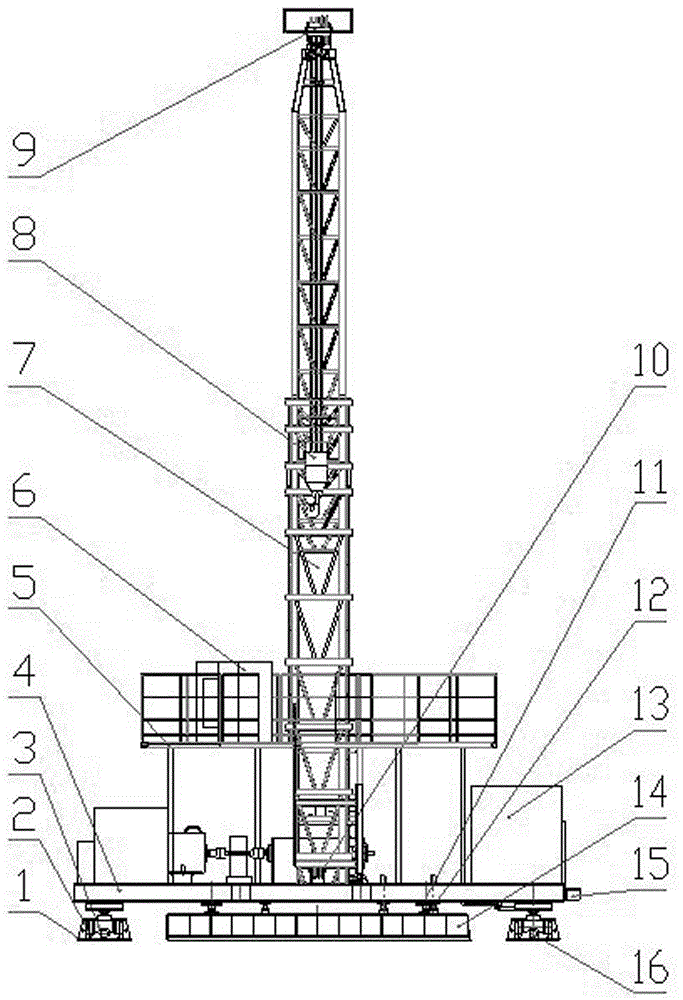

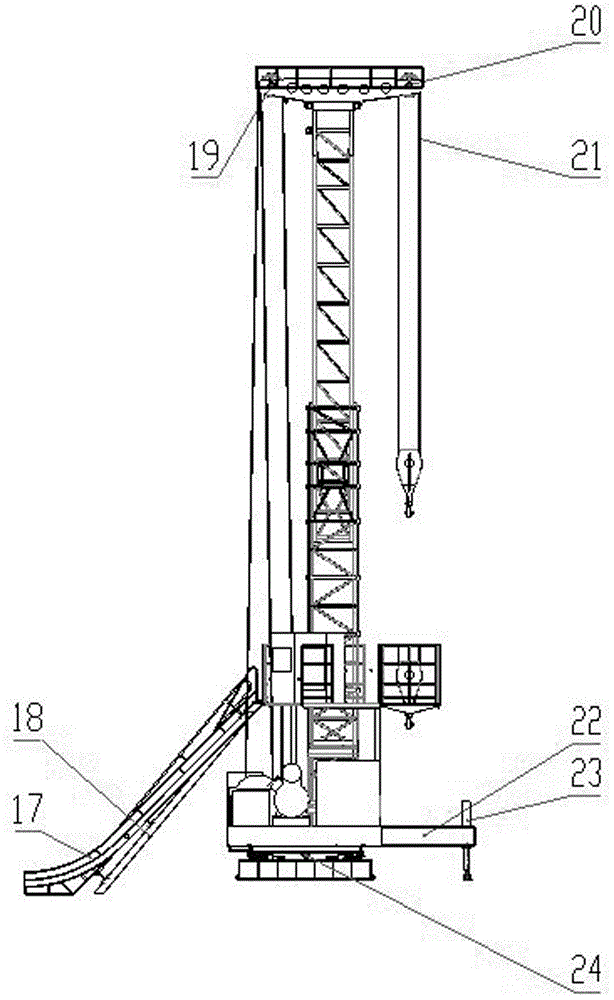

[0017] The stepping self-balancing derrick workover rig is composed of a stepping flat car and a top loading operation part.

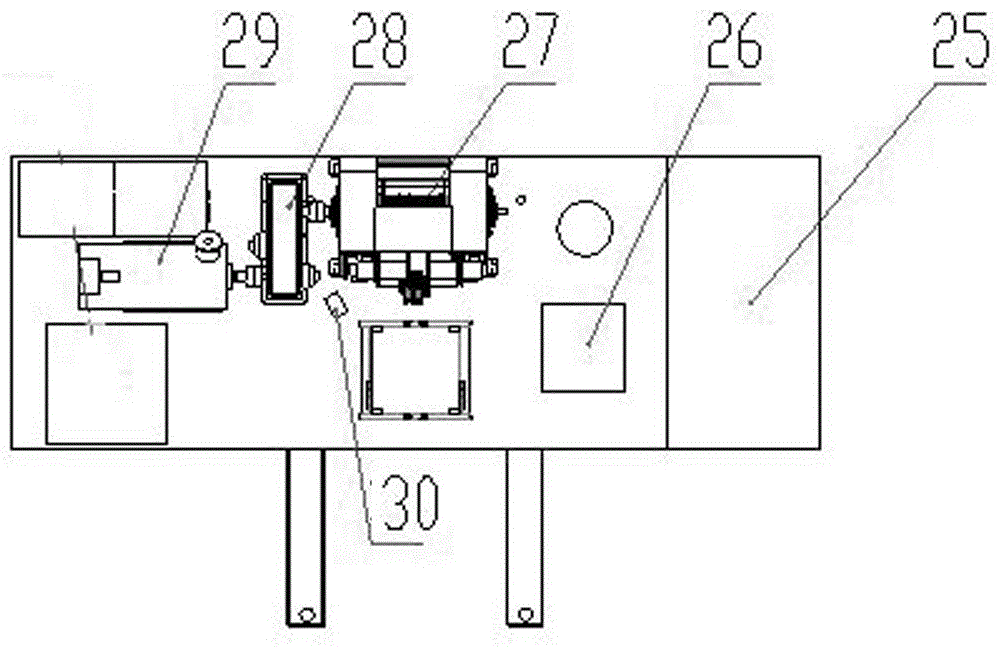

[0018] The stepping flat car is composed of a long walking boat 14, a short walking boat 1 and a pressure-bearing platform 4. The pressure-bearing platform 4 and the long walking boat 14 are connected together by a lifting cylinder 11, which can be adjusted by the telescopic adjustment of the lifting cylinder 11 during operation. Workover rig balance. The short boat 1 and the pressure platform 4 are connected by a rotating shaft 24, and the short boat 1 and the pressure platform 4 can slide or rotate relative to each other. Two walking dollies 3, two walking tracks 2 and a walking oil cylinder 16 are all housed in the walking short boat 1 and the walking long boat 14. One end of the walking oil cylinder 16 is connected with one of the walking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com