Eccentric vibration device of road roller and arranging structure thereof

A technology of vibrating device and arranging structure, applied in the field of vibration of road rollers, can solve the problems of difficult adjustment, different tolerance, difficult installation, etc., and achieve the effect of reducing the difficulty of manufacturing and installation, high stability and reliability, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

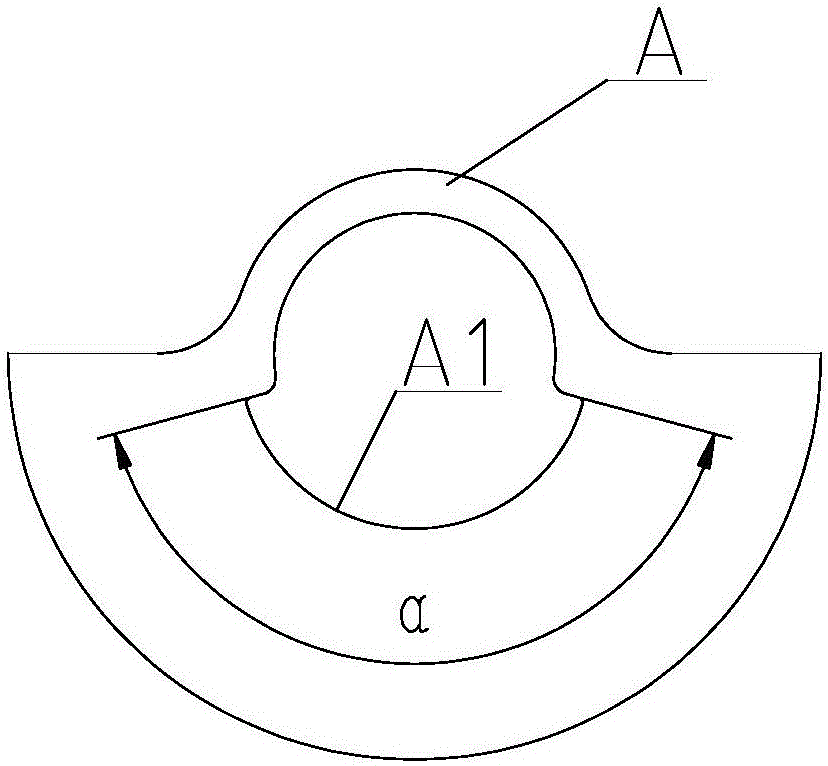

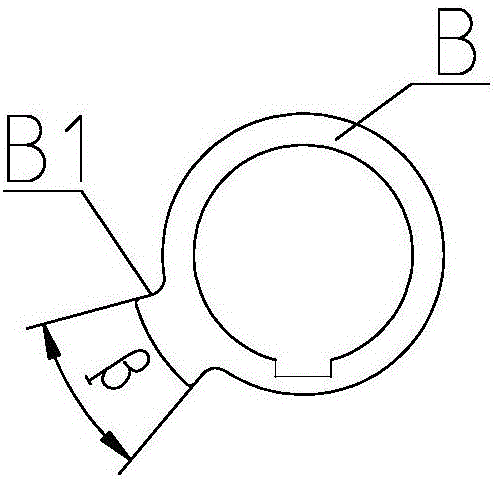

[0086] Embodiment 1, only the movable eccentric mass group is set on the vibration axis

[0087] If the fixed eccentric block group is not provided on the vibration shaft, but only the movable eccentric block group is provided, the position of the movable eccentric block group on the same vibration shaft has the following setting methods:

[0088] In the first arrangement mode, the movable eccentric mass group is symmetrically arranged on both sides of the vibration axis along the center of the vibration axis;

[0089] The second setting method, wherein one set of movable eccentric mass groups is arranged in the middle of the vibration axis, and all other movable eccentric mass groups are symmetrically arranged on both sides of the vibration axis along the center of the vibration axis;

[0090] You can choose one of the above two setting methods during installation.

Embodiment 2

[0091] Embodiment 2, the fixed eccentric block and the movable eccentric block are set on the same vibration axis at the same time

[0092] The device also includes a fixed eccentric mass set arranged on the vibrating shaft, the fixed eccentric mass set and the movable eccentric mass set are independently arranged; the fixed eccentric mass set and the movable eccentric mass set cooperate with each other so that when When the vibration axis rotates forward or reversely, the vibrations of the fixed eccentric mass set and the movable eccentric mass set are superimposed or canceled each other.

[0093] The positions of the fixed eccentric block group and the movable eccentric block group on the same vibration axis are set as follows:

[0094] In the first setting mode, the fixed eccentric mass group is symmetrically arranged on both sides of the vibration axis along the center of the vibration axis, and the movable eccentric mass group is also symmetrically arranged on both sides ...

Embodiment 3

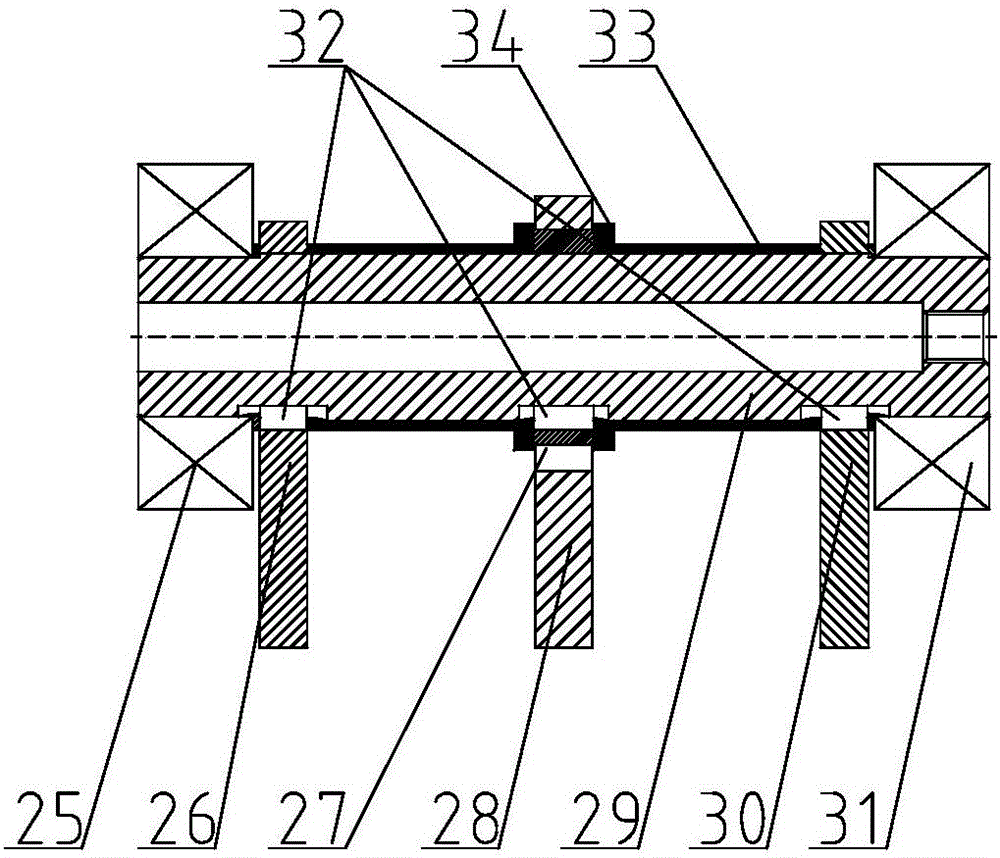

[0110] Embodiment 3, set movable eccentric block group and / or fixed eccentric block on different vibration axes

[0111] Embodiment 3.1 The vibration shaft is set to two, and the two vibration shafts are arranged symmetrically along the central axis of the exciter housing; The eccentric moments of the eccentric mass groups on the vibrating shaft are equal to each other. The positions of the eccentric block groups on the two vibration axes are set as follows:

[0112] In the first setting mode, the two vibrating shafts are equipped with movable eccentric block groups and only;

[0113] In the second setting method, one vibration shaft is provided with a movable eccentric block group, and the other vibration shaft is provided with a fixed eccentric block group;

[0114] In the third setting mode, a movable eccentric block group and a fixed eccentric block group are arranged on one vibrating shaft, and a movable eccentric block group is arranged on the other vibrating shaft;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com