A track-laying machine with automatic span change during the traveling process and its application method

A track-laying machine and automatic technology, which is applied in the field of engineering technology and science, can solve the problems of labor and time-consuming, repeated disassembly and assembly, etc., and achieve the effect of realizing intrinsic safety, improving construction speed and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The utility model relates to the structural composition of an automatic span-changing track-laying machine during the traveling process.

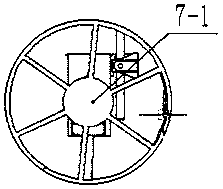

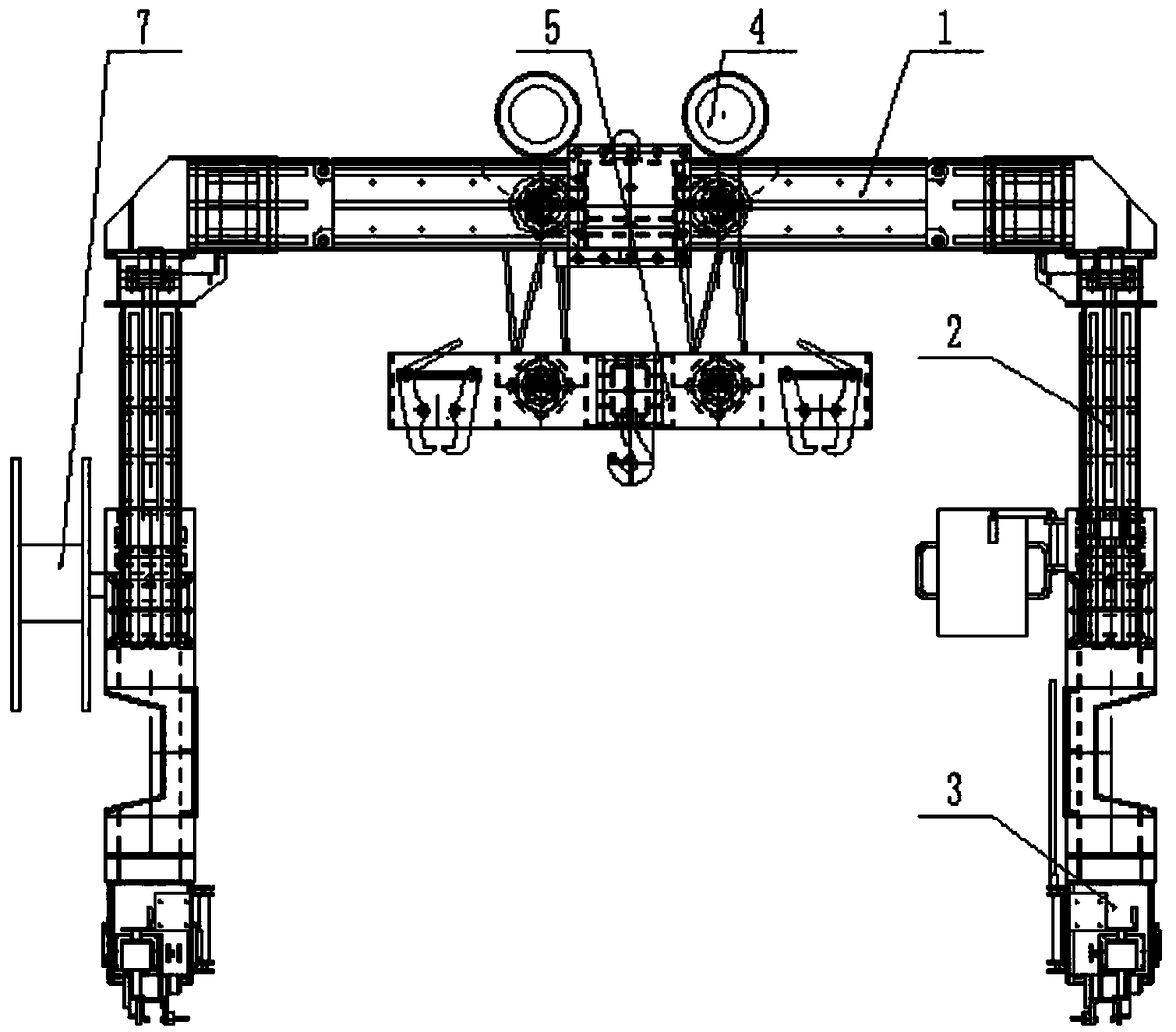

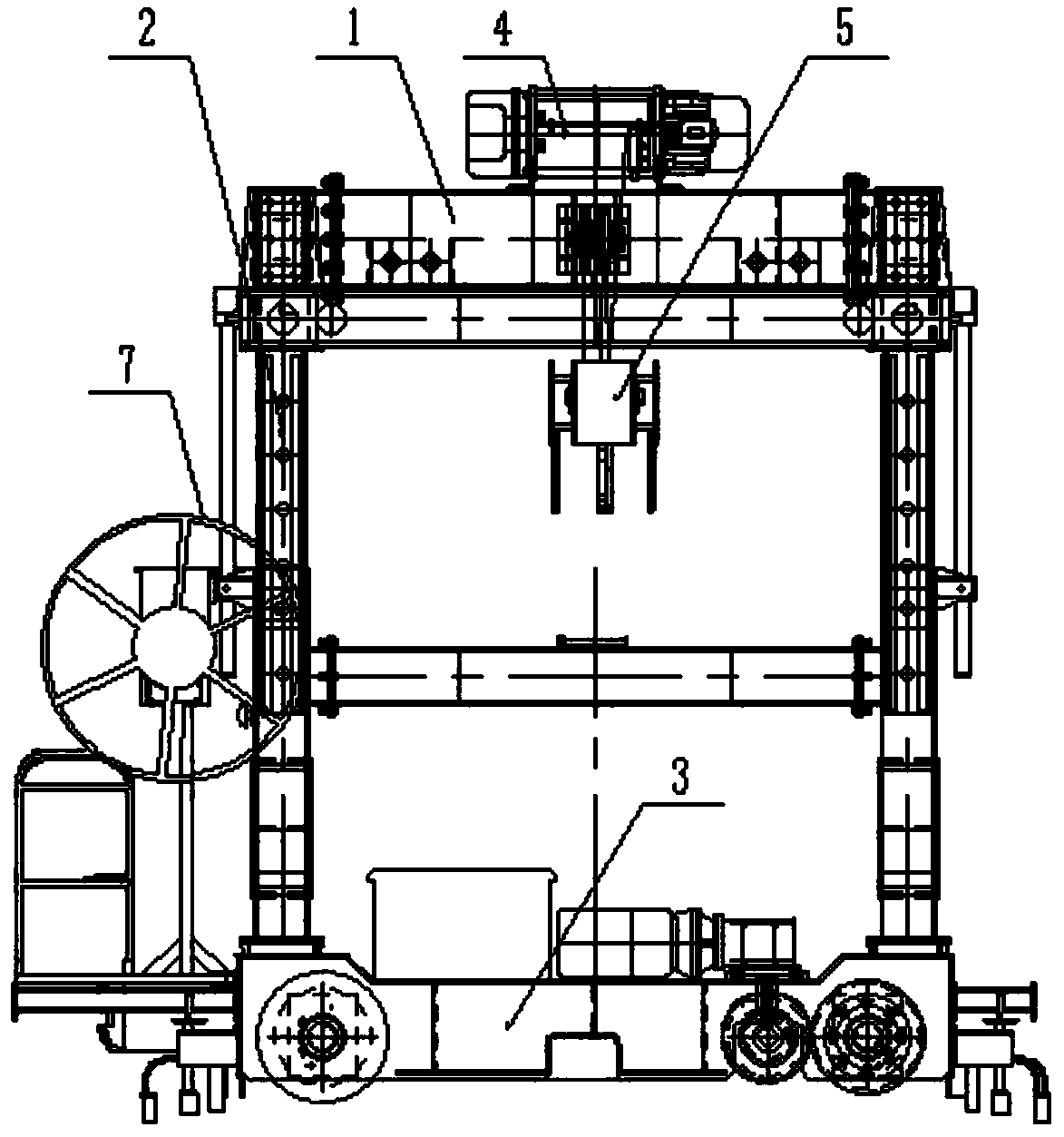

[0052] The design of the present invention is mainly composed of seven parts, which are: guide column type upper beam assembly 1, outrigger assembly 2, running beam assembly 3, lifting system 4, rail pole pole 5, and lateral movement variable span system 6 electrical control system, etc. Such as Figure 1a , 1b , 1c shown.

[0053] The guide column type upper beam assembly 1 is an "I"-shaped structure as a whole, and is composed of an upper beam connecting beam 1-1, an upper beam guide column 1-2, and an upper beam guide column extension section 1-3, and each part is A box structure made of welded plates. The middle parts of the two upper beam guide columns 1-2 are equipped with flanges, which are connected by the flanges at both ends of the upper beam connecting beam 1-1 to form an "I"-shaped structure, and the upper beam guide c...

Embodiment 2

[0063] How to use the automatic span-changing track-laying machine during the traveling process.

[0064] 1. The track laying machine is transported and hoisted to the site of the track laying base, rotated and stretched to connect the extension section 1-3 of the upper beam guide column, rotate the control panel to the operating position, debug the whole machine, hoist it down to the main line with the base crane, and use the rail car to pull through the main line. The line travels to the working surface of the track-laying section, and the track-laying machine is operated to raise it to the height required for the operation, and insert the outrigger guide sleeve 2-1 outrigger guide column 2-2 to connect the pin shaft.

[0065] 2. Install the transition rail from the main line to the section running rail, operate the track laying machine to automatically change the span along the transition rail to the section running rail 8-2, insert the upper beam guide sleeve 2-5, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com