Method and device for treating organic wastewater

A treatment device and technology for organic wastewater, applied in water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. Evaporation system energy consumption increases and other issues, to prevent scaling problems, ensure efficient heat exchange, and avoid equipment scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

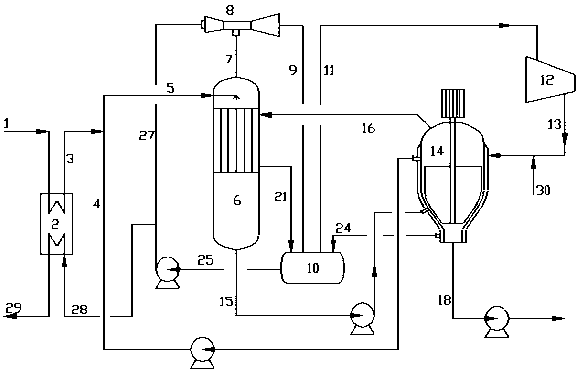

[0072] use figure 1 The device, the falling film evaporator adopts figure 2 In the device, the organic wastewater used is acrylonitrile production wastewater, the Kjeldahl nitrogen content in the acrylonitrile wastewater is 4050mg / L, the boiling point of the wastewater is 100°C, and when the wastewater evaporates more than 80wt% of the water, the raw wastewater treatment capacity is 15t / h, normal temperature wastewater is preheated to 99°C through the preheater 2, mixed with the 104°C concentrated solution, and enters the evaporator 6. The flow ratio of raw material wastewater to concentrated liquid wastewater is 3:1-1.5. The evaporation temperature of the waste water in the evaporator 6 is 100° C., the vacuum degree of the ejector gas phase steam inlet is 15 kPa, and the compression ratio of the steam compressor 12 is 1.5. The evaporation temperature in the fouling device 14 is 104°C. Two scrapers are installed in the fouling device 14, and the rotation speed of the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com