A curved shell and its forming process

A molding process and shell technology, applied in the direction of coating, etc., can solve the problems of difficult repair of the overall structure, weak anti-drop strength, difficult maintenance, etc., and achieve excellent dustproof and waterproof performance, strong dustproof and waterproof function, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

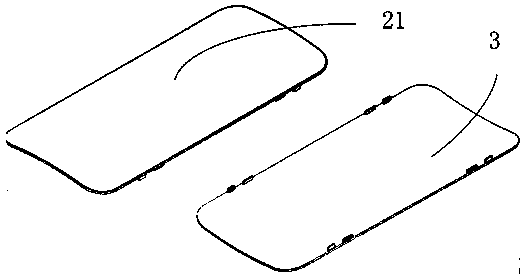

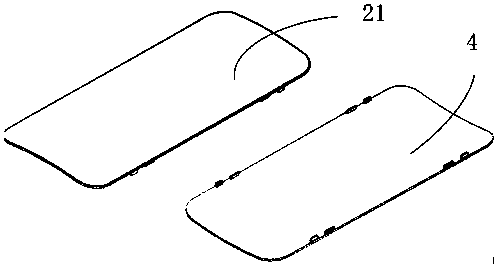

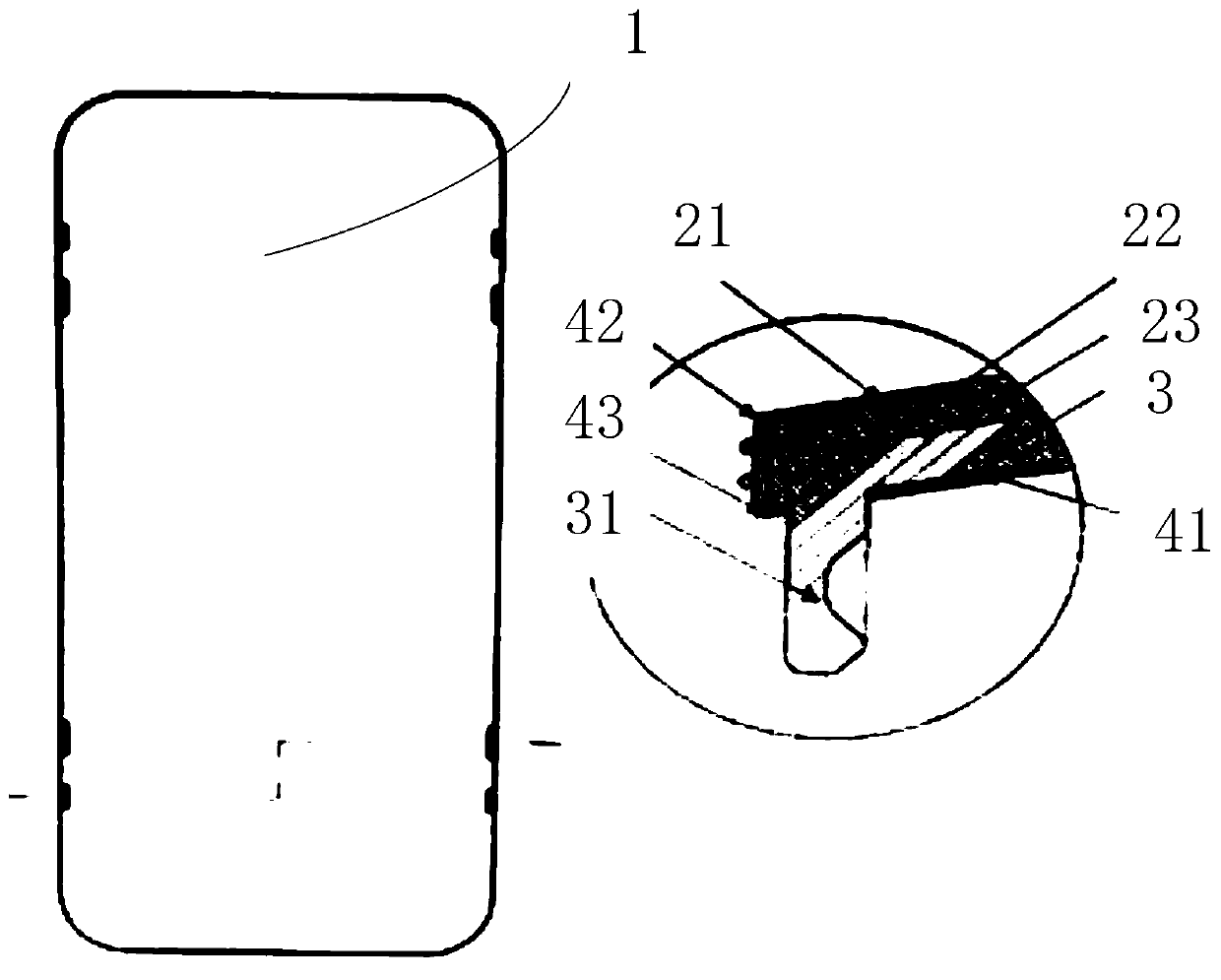

[0047] refer to Figure 1-6 as shown in figure 1 As shown, it includes a housing 1, and the housing 1 is a curved surface; the housing 1 includes a base layer 2 and a connecting layer 3; the base layer 2 is a curved surface; the base layer 2 is provided with a first layer Pattern 22; the base layer is installed on the surface of the object to be installed through the connection layer 3 . The housing 1 also includes a sealing layer 4; the sealing layer 4 seals the connecting layer 3; combined figure 1 , figure 2 As shown, the base layer 2 and the connection layer 3 are snap-connected, and the base layer 2 is inlaid on the surface of the connection layer 3 ; the edge of the connection layer 3 is provided with a release 31 . The contact surface between the base layer 2 and the connection layer 3 is provided with a second layer patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com