Robot zero position calibration method based on electromagnetic encoders

A zero-point calibration and robot technology, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of time-consuming precision, complicated operation process, and expensive measuring equipment, so as to improve the accuracy of zero-position alignment and save operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

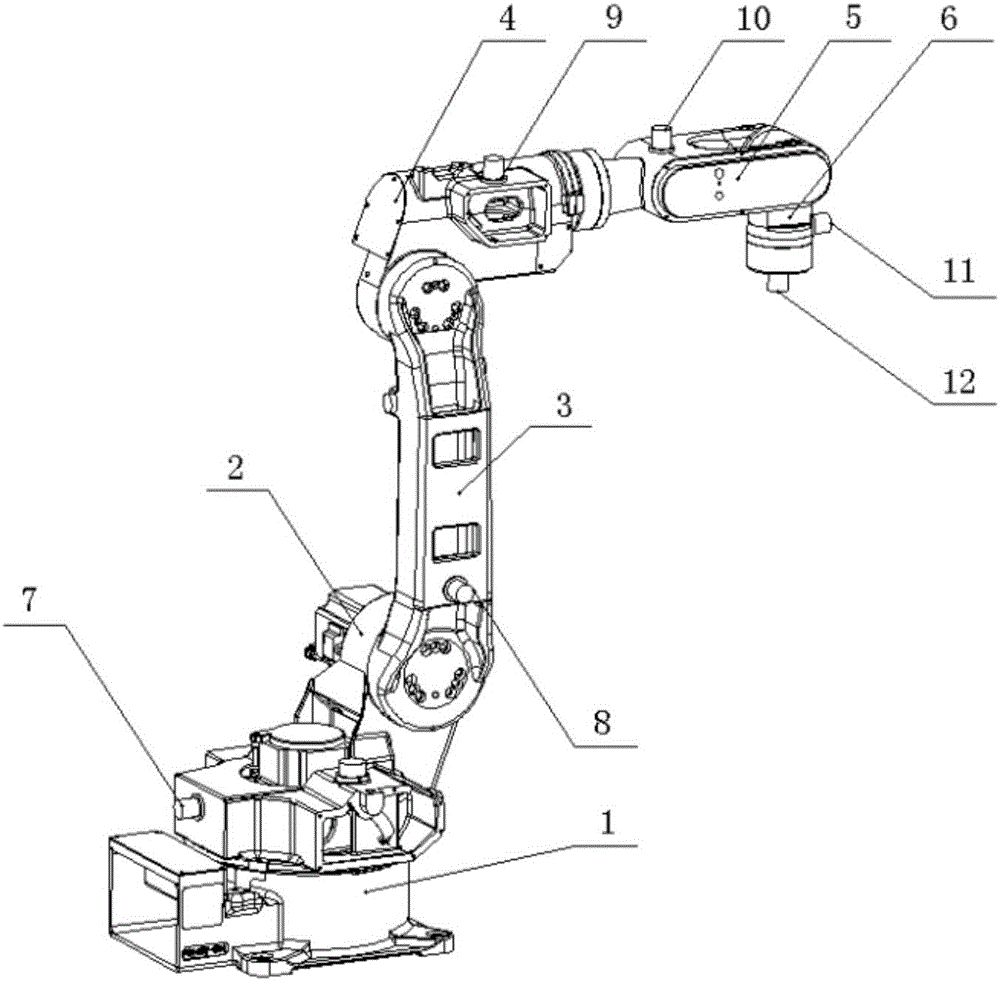

[0022] Such as figure 1 As shown, it is a schematic structural diagram of a typical industrial robot. The robot body is installed on the workbench through the base (not shown in the figure), and the 1-6 axes of the robot are connected in series above the base, that is, the base joint 1 and shoulder joint 2 of the robot. , the upper arm joint 3, the elbow joint 4, the forearm joint 5 and the wrist joint 6, and each axis is connected by a rotary joint. At the same time, the first electromagnetic encoder 7, the second electromagnetic encoder 8, the third electromagnetic encoder 9, the fourth electromagnetic encoder 10, the fifth electromagnetic encoder 11 and the sixth electromagnetic encoder are respectively installed on the 1-6 axes. 12.

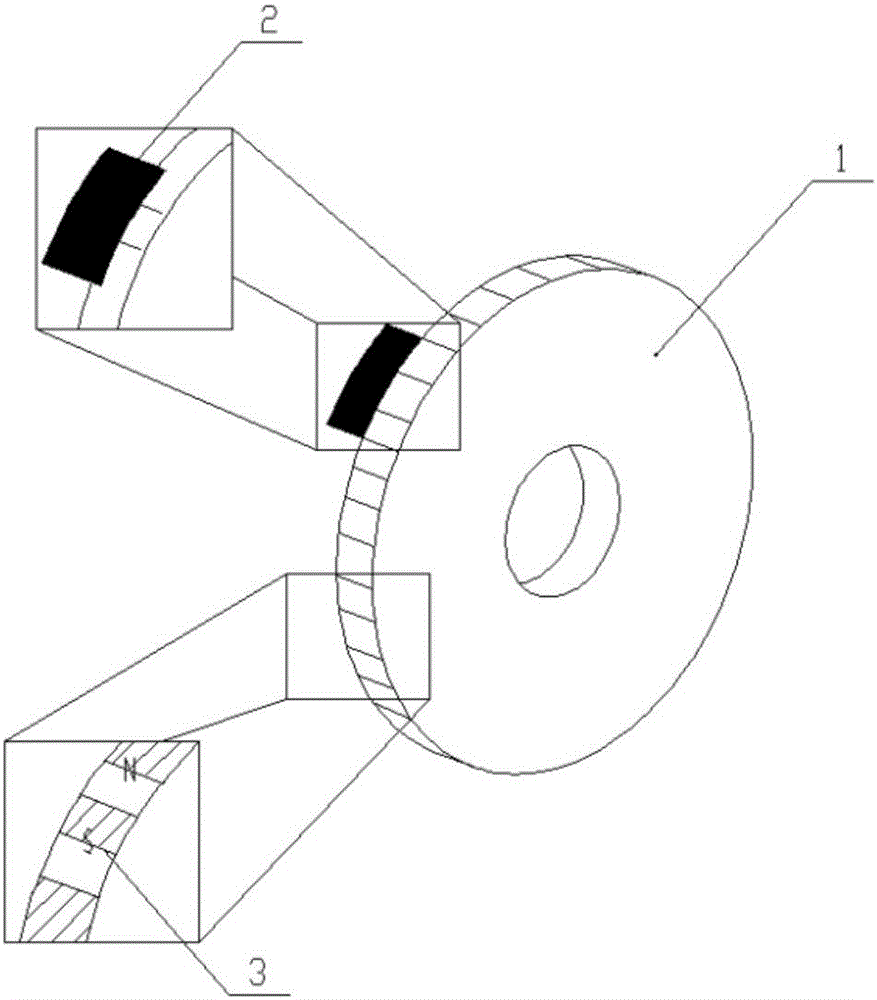

[0023] Using the working principle of electromagnetic encoder for zero calibration must first ensure the correct installation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com