Mini-screw and nut assembly auxiliary assembling tool and assembling method

An auxiliary assembly and nut technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of easy sliding, low assembly efficiency, and redundant objects, and achieve the effect of simple operation, improving assembly efficiency, and avoiding redundant objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

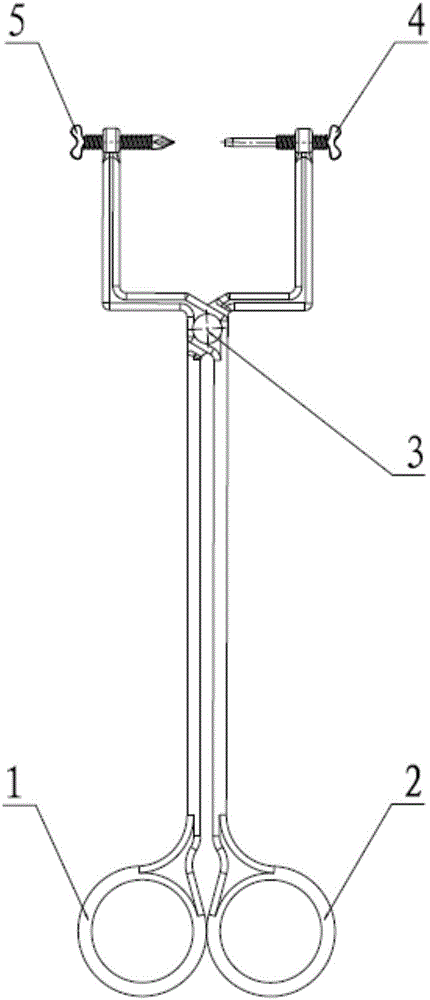

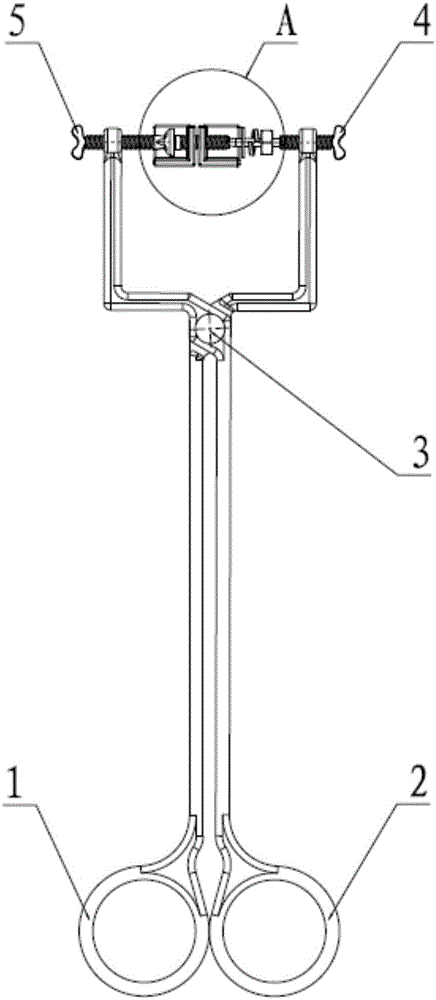

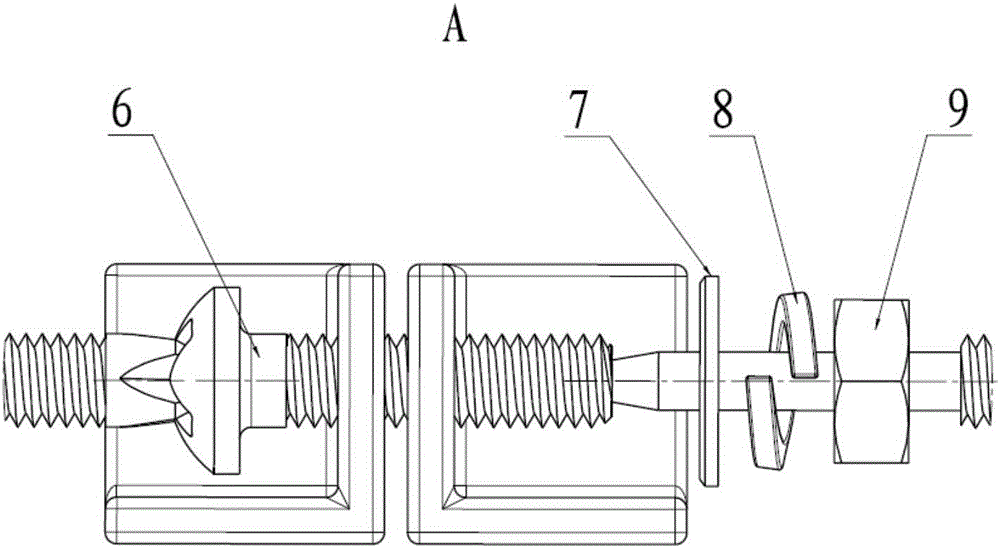

[0053] Such as Figure 4 As shown, in an aerospace product, the connector needs to be installed and fixed inside the cabin through a miniature screw and nut assembly. Such as Image 6 As shown, the inner diameter of the cabin is R70mm, and the space available for assembly operations inside the cabin is very narrow, and it is difficult to complete the assembly operation of the miniature screw and nut assembly without tools.

[0054] In the traditional assembly process, tools such as tweezers and needle-nose pliers are generally used to assist assembly. During assembly, the miniature screw and nut assembly tends to slip off, leaving excess in the product. Due to the special requirements of aerospace products, the excess must be cleaned. Generally, the excess is cleaned by dumping or disassembling a single machine, which increases the difficulty of assembly and wastes assembly time. At the same time, the traditional assembly process is inefficient and difficult to meet the sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com