Device for realizing reference self-adaptive function

An adaptive and functional technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of many production processes, high precise positioning requirements, affecting production efficiency, etc., to reduce production costs, improve assembly efficiency, and simplify The effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

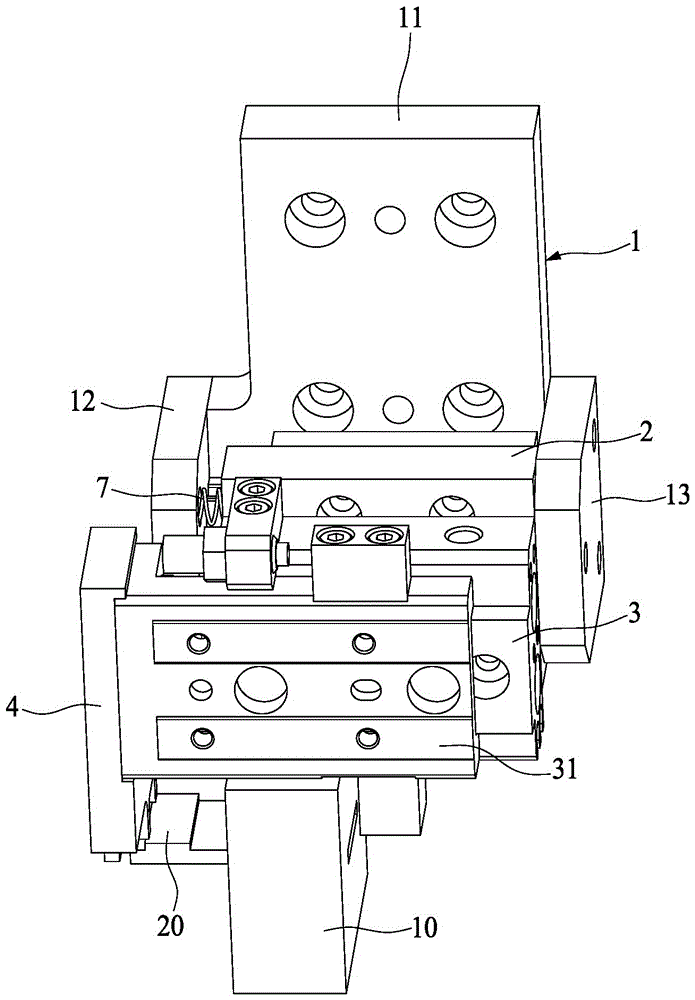

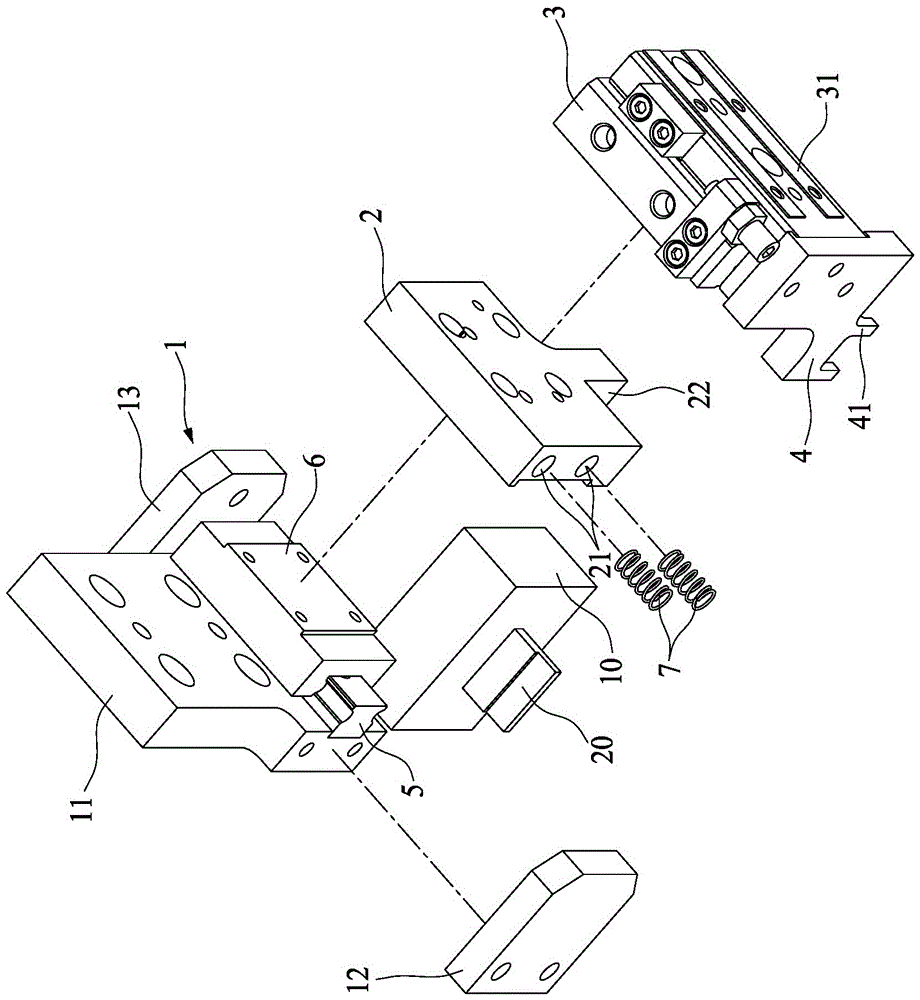

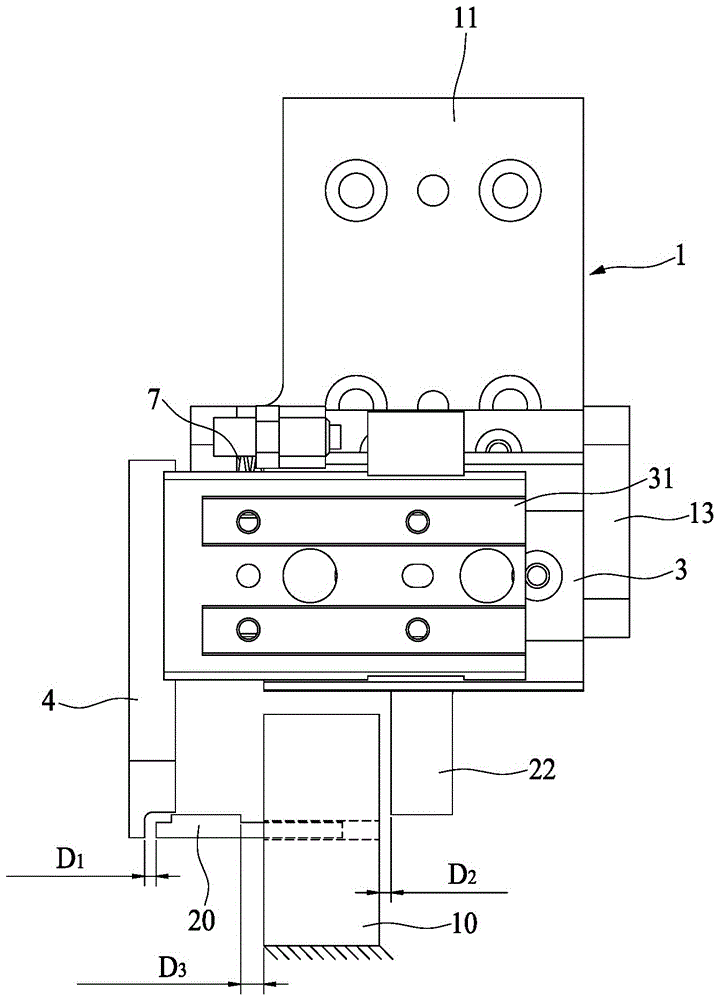

[0030] see Figure 1 to Figure 6 As mentioned above, a device for realizing the datum self-adaptive function disclosed in the present invention includes a seat body 1 , a fence 2 , a cylinder 3 and a press-in block 4 .

[0031] The grid 2 is slidably installed on the base body 1. In this embodiment, the base body 1 is provided with a slide rail 5, the slide rail 5 is provided with a slider 6, and the slide block 6 slides left and right on the slide rail 5. The grid 2 is installed on the Slider 6 on. A spring 7 is installed between the grid 2 and the seat body 1, two springs 7 are installed up and down, and two installation grooves 21 of the spring 7 are correspondingly arranged on the grid 2, and the grid 2 is formed to abut against the first workpiece 10 The abutment part 22.

[0032] The cylinder 3 is installed on the grid 2, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com