Ultrasonic welding device for wire harness and rapid forming welding system

A welding device and welding system technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem that it is difficult to achieve a good balance between equipment operating efficiency and accuracy, quality and safety are difficult to guarantee, and it affects popularization and application. To avoid problems such as the prospect of manual welding and clamping, the structure is compact and the space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

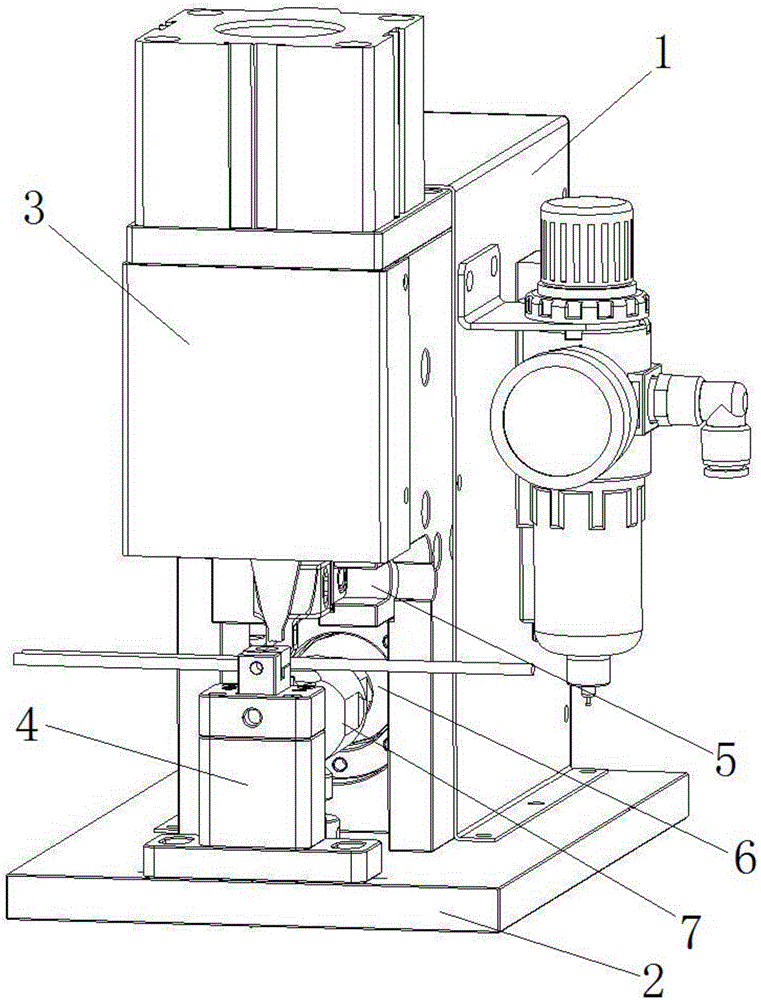

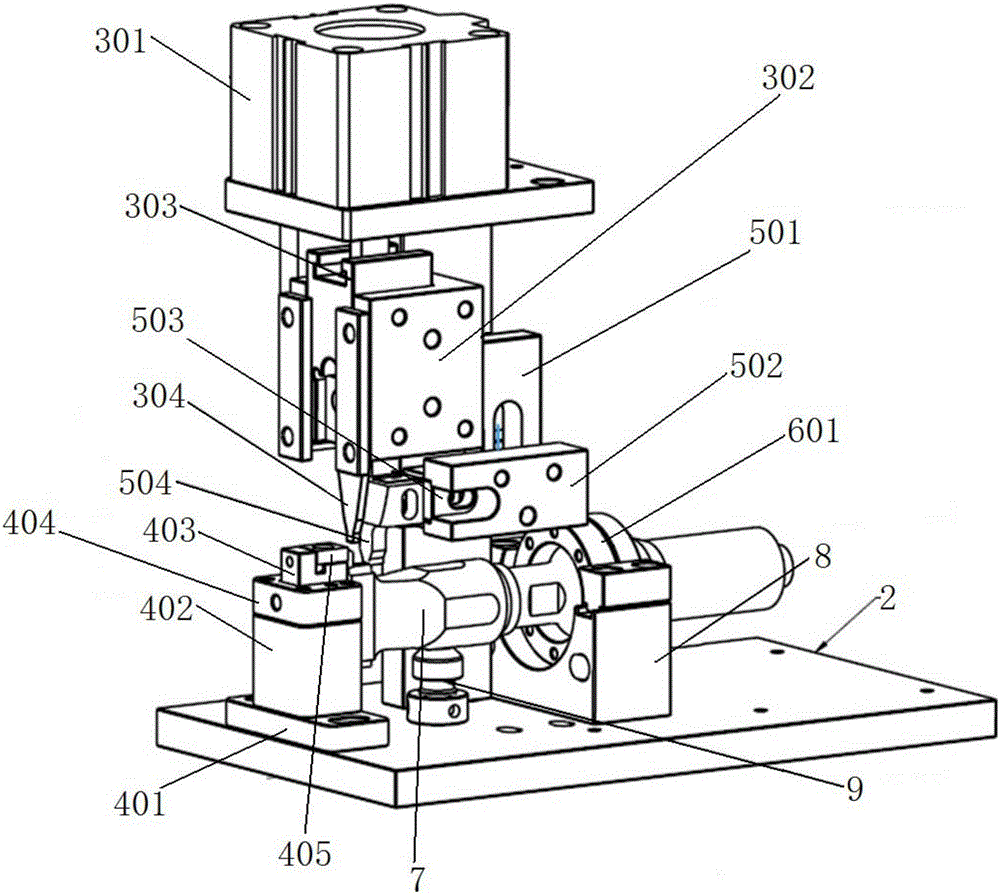

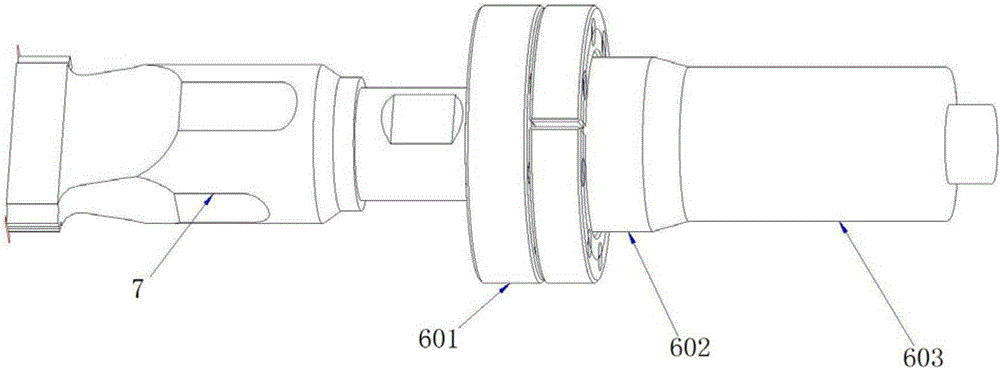

[0024] Such as figure 1 and figure 2 As shown, the present invention is achieved in this way, an ultrasonic wire harness welding device, which includes a base 2, a body 1 fixed on the base 2, an ultrasonic transducer assembly 6, and a welding mold 7 connected to the ultrasonic transducer assembly 6. The structural feature is that it also includes a longitudinal adjustment assembly 3 and a horizontal adjustment assembly 5 connected to the body 1 for adjusting and fixing the position of the wire to be welded, and the base 2 is also provided with a fine adjustment assembly that cooperates with the longitudinal adjustment assembly 3 4. When the present invention is working, the ultrasonic energy is converted by the ultrasonic transducer assembly 6 and transmitted to the welding line through the welding mold 7. Before welding, the vertical adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com