Mechanism for driving core pulling of inclined mold core through sliding block

An oblique core-pulling and slider technology, which is applied in the field of core-pulling mechanisms, can solve problems such as large product size errors, increased mold costs, and high injection pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

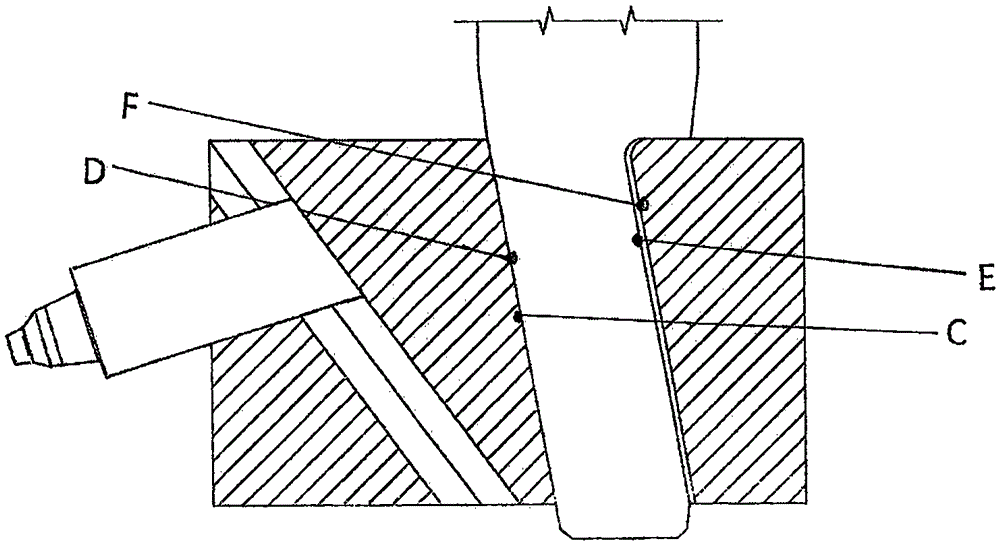

[0022] As shown in the figure, it is a mechanism that uses the slider to drive the oblique core to pull the core. Its specific implementation is as follows. (375), movable template (175), first wear block (575), second wear block (675), first screw (35), second screw (25), fixed template (775), the The two sides of the slider (475) are provided with T-shaped bosses, the center of the slider (475) is provided with a square oblique through hole, and the left side of the slider (475) is provided with an inclined surface. T-shaped groove, the slide block (475) is installed in the concave T-shaped groove provided on the moving template (175), and the forming slide block ( 55), the right side of the forming slide block (55) is provided with concave-convex T-shaped grooves, and the set concave-convex T-shaped grooves cooperate with the concave T-shaped grooves on the inclined surface of the slide block (475) to form a sliding gap, and the forming slide block ( 55) is fastened to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com