Flexible automatic spraying device for woodworking industry

An automatic spraying and flexible technology, applied in the direction of the spraying device, can solve the problems of uneven spraying quality, low efficiency, and increased enterprise costs, and achieve the effects of comprehensive angle adjustment range, small overall volume, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

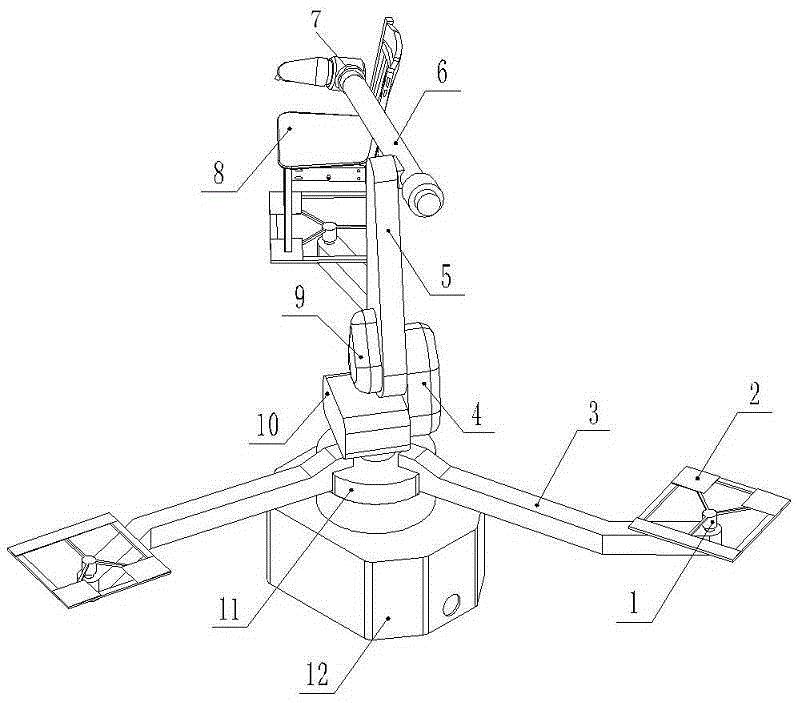

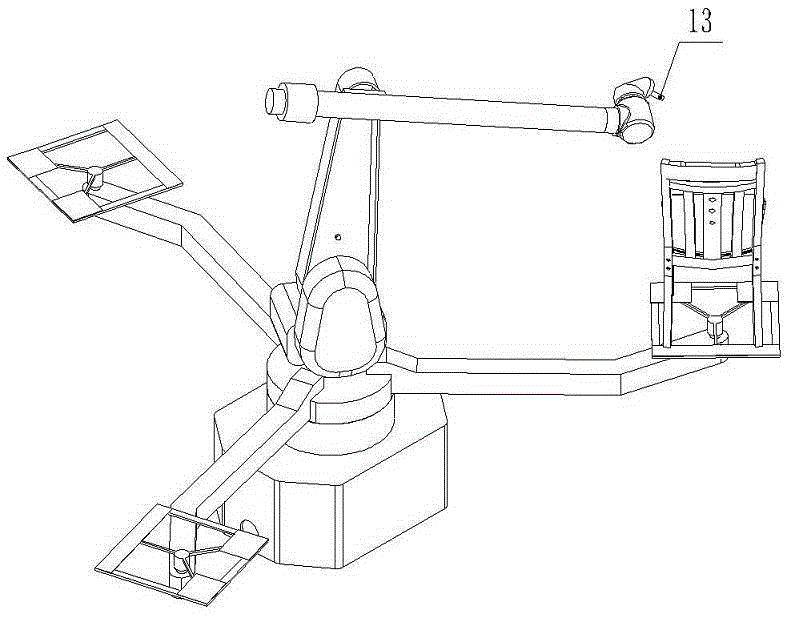

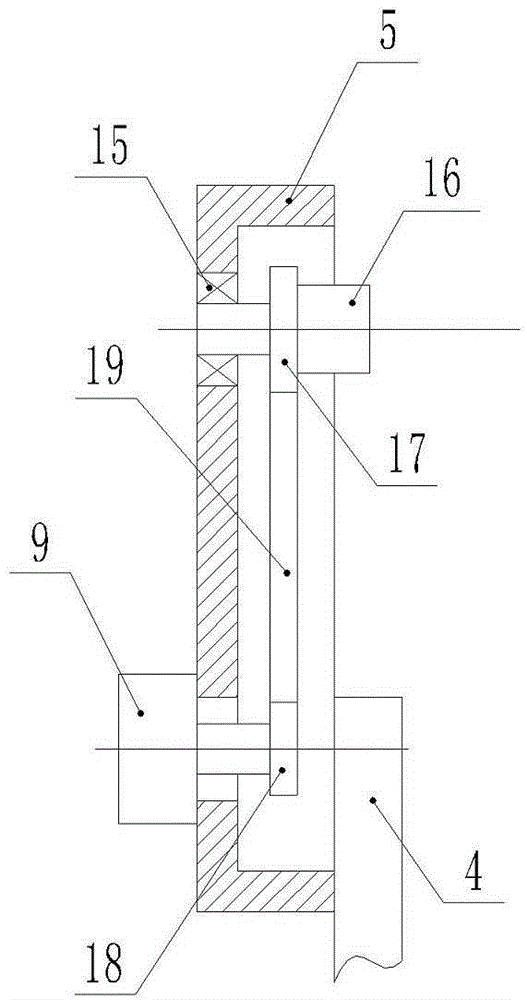

[0045] Such as Figure 1-8 As shown, it shows a specific embodiment of the present invention. As shown in the figure, the flexible automatic spraying device for woodworking industry disclosed by the present invention includes a rotating bracket 1, a discharge tray 2, a rotating arm 3, a first Connecting rod 4, belt cover 5, flexible arm 6, end assembly 7, second motor 9, first motor 10, turntable 11, base 12, spray gun 13 and belt drive assembly; said belt drive assembly includes bearing 15, rotating shaft 16, driven wheel 17, driving wheel 18 and synchronous belt 19;

[0046] As shown in the figure, the discharge tray 2 for placing the furniture 8 to be sprayed is fixedly installed on the rotating bracket 1, and the rotating bracket 1 is installed on the end of the rotating arm 3, and the rotating disc 11 is evenly distributed along the circumferential direction. There are three installation grooves, the rotating arm 3 is installed in the installation groove on the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com