Magnetic suspension rotor harmonic current inhibition method based on parallel FORC and phase lag-lead compensation

A magnetic levitation rotor and harmonic current technology, applied in the direction of electrical components, adaptive control, general control system, etc., can solve the problems that parallel multiple traps cannot be suppressed at the same time, large amount of calculation, complex design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

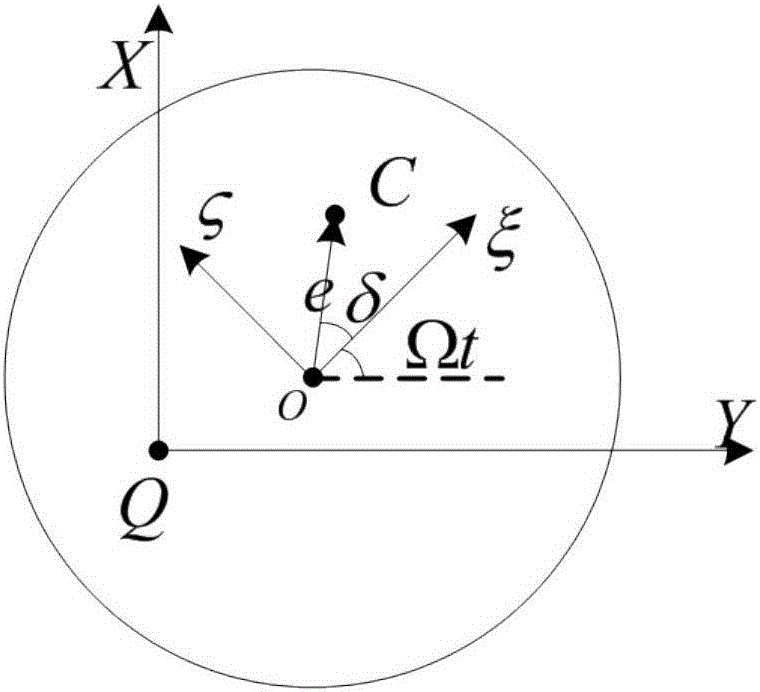

[0127] Such as figure 1 As shown, the implementation process of a magnetic levitation rotor harmonic current suppression method based on parallel FORC and phase lag-lead compensation is: firstly establish a magnetic levitation rotor dynamics model including mass unbalance and sensor harmonics; then design a parallel based The harmonic current suppression method of FORC and phase lag-lead compensation; finally, a method of fast adaptive adjustment of controller gain based on the signal energy point of view is applied to realize the dynamic optimization of system dynamic performance and steady-state performance.

[0128] Step (1) Establish a maglev rotordynamics model with mass unbalance and sensor harmonics

[0129] Schematic diagram of the structure of the magnetic levitation rotor system. figure 2 As shown, it is mainly composed of a perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com