Electric driving unit, chopper circuit, DC motor and electric equipment

An electric drive, DC motor technology, applied in the direction of connection with control/drive circuits, DC motor speed/torque control, electromechanical devices, etc., can solve the problem of limited battery voltage amplitude, current sharing failure, poor current sharing effect, etc. problems, to avoid the consumption of human and financial resources and reduce the requirements of performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

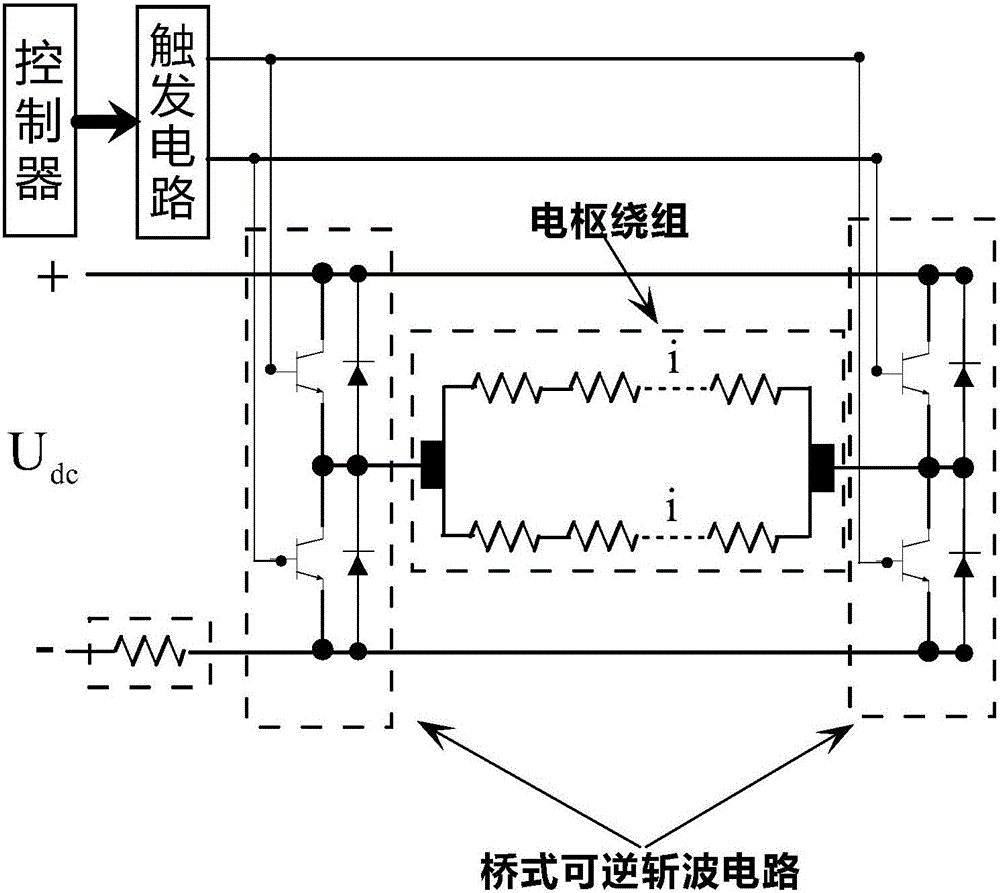

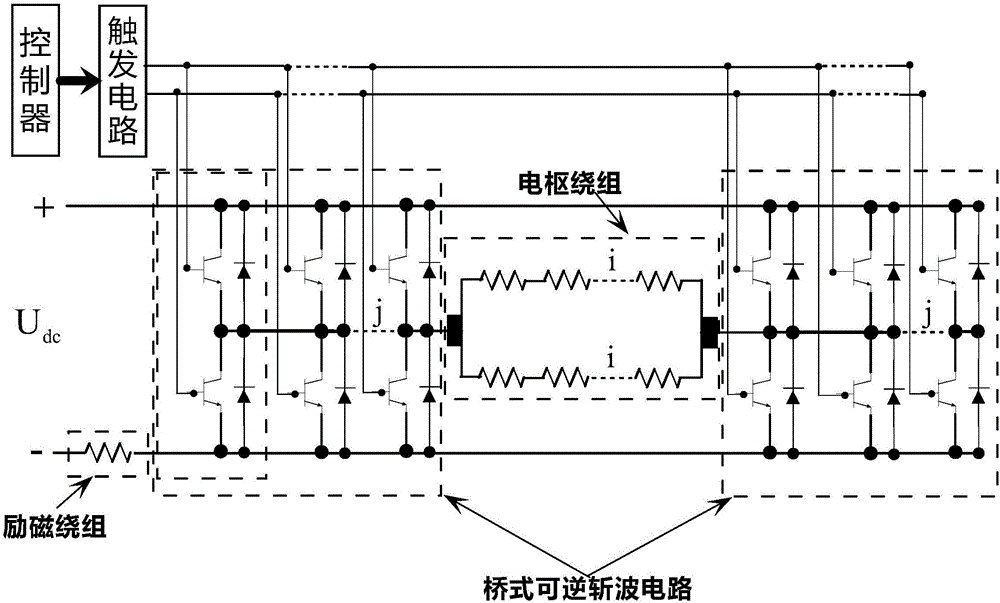

[0037] figure 1 is a schematic diagram of the circuit structure of the electric drive device in this embodiment.

[0038] The electric driving device 10 is installed in electric equipment such as electric tools, quadcopters, electric vehicles, electric boats, industrial electric forklifts, and electric military equipment, and is used to drive the electric equipment. Such as figure 1 As shown, the electric driving device 10 includes a DC motor 11 , a DC power supply, a bridge reversible chopper circuit 12 , a main magnetic pole 13 , a controller 14 and a trigger circuit 15 .

[0039] The DC motor 11 has a rated voltage and a rated current. The DC motor 11 has 2j mutually independent armature winding branches 16 , 2j×m commutator segments (not shown in the figure) and 2 sets of brush sets 17 .

[0040] The armature winding branch 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com