Motor type antitheft blade lock

A blade lock and motor-type technology, applied in the mechanical field, can solve the problems of low safety performance, high power consumption, high battery replacement frequency, etc., and achieve the effect of simple structure, convenient operation, and improved safety and anti-theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

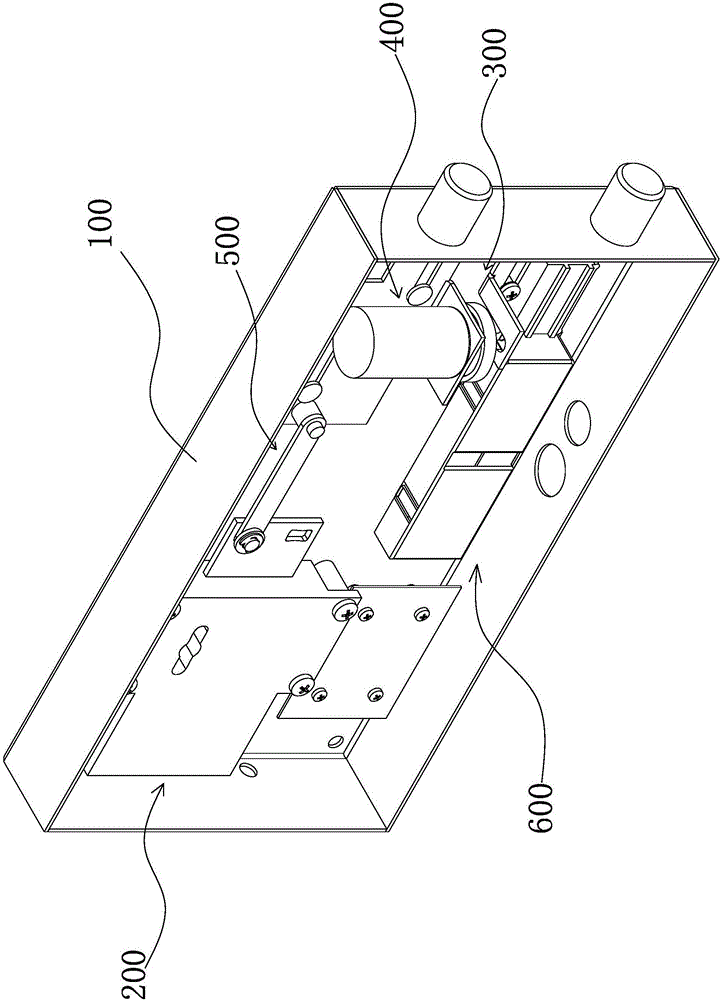

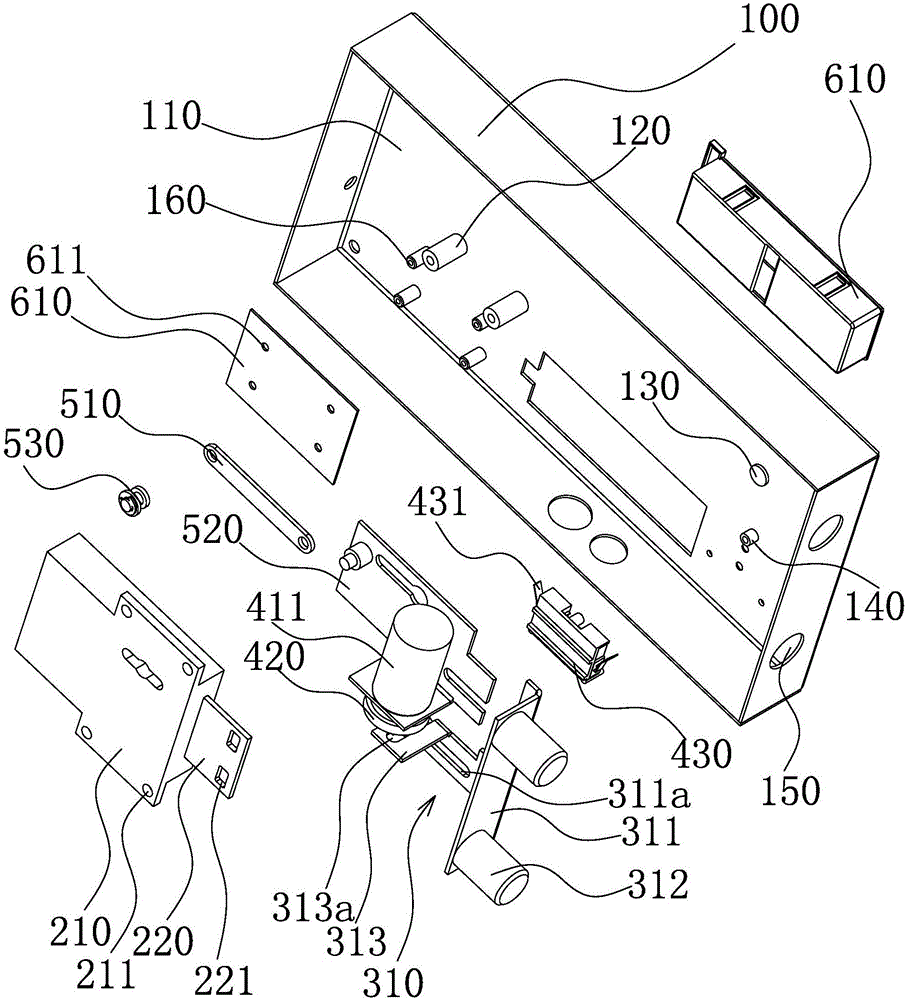

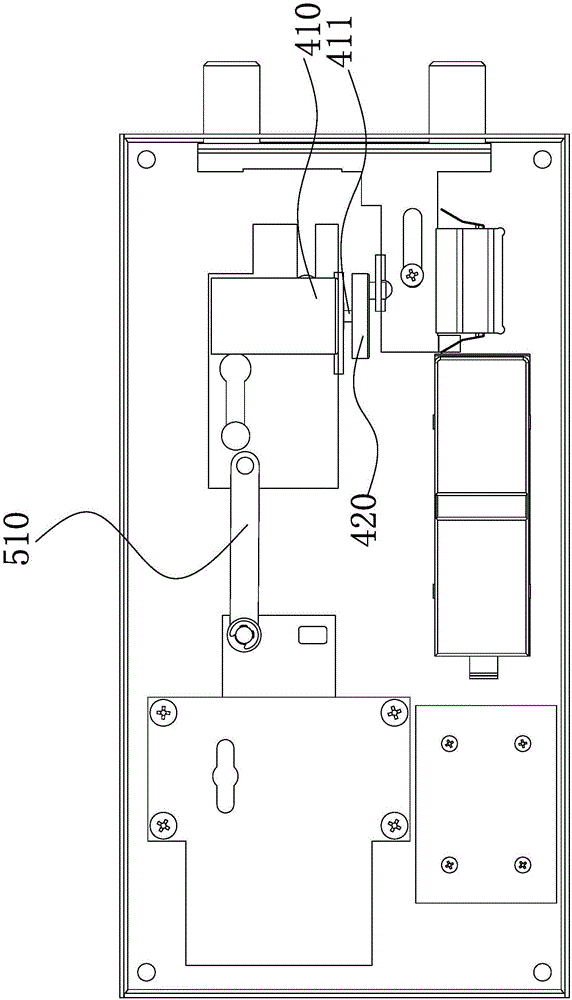

[0040] Such as figure 1 and figure 2 As shown, a motor-type anti-theft blade lock provided by the present invention includes: a housing 100; a locking assembly 200 detachably connected to the housing 100 as a motorized part for unlocking or locking; a slide assembly 300 that can It is detachably connected to the housing 100 and can slide relative to the housing 100; the drive assembly 400 is connected with the slide assembly 300, and drives the slide assembly 300 to move horizontally through the drive assembly 400, thereby realizing the opening and closing of the blade lock.

[0041] When a key is inserted or a password is entered, the driving assembly 400 rotates forward / reversely, driving the slide assembly 300 to retr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com