Crystal boat

A technology of wafers and elastic parts, applied in the field of locking structures of wafer boats, can solve problems affecting product yield, product scrapping, and a large number of metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

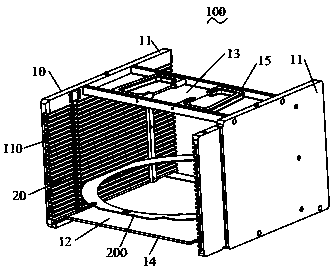

[0032] Such as Figure 1-13 As shown, the wafer boat 100 of the present invention is used for accommodating wafers 200 and can be placed on the horizontal surface of a working platform (not shown). The wafer boat 100 includes a main body 10 , a bar 20 installed on the main body 10 , and an automatic locking component 30 installed on the main body 10 .

[0033] Such as figure 1 and 2 As shown, the main body 10 includes a pair of sidewalls 11 arranged at intervals, a storage space 12 between the pair of sidewalls 11 for accommodating the wafer 200 , and a horizontally arranged top wall connecting the pair of sidewalls 11 13 , and a bottom wall 14 arranged parallel to the top wall 13 at intervals and connecting the pair of side walls 11 . A handle 15 is disposed on the top wall 14 .

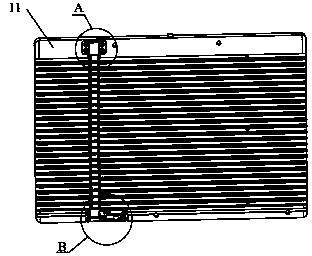

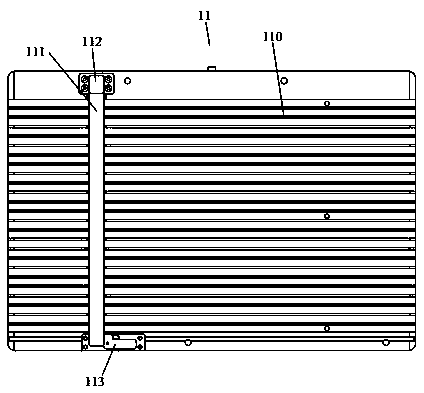

[0034] Such as Figure 1-3 As shown, the pair of side walls 11 are vertically arranged, and each side wall 11 is provided with a plurality of storage tanks 110 arranged at intervals horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com