A kind of prefabricated cavity type medium thin-walled concrete shear wall

A technology of concrete shear walls and cavities, which is applied to walls, buildings, building components, etc., can solve problems affecting the construction period of prefabricated concrete structures, and achieve the effects of reducing self-weight, avoiding damage, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

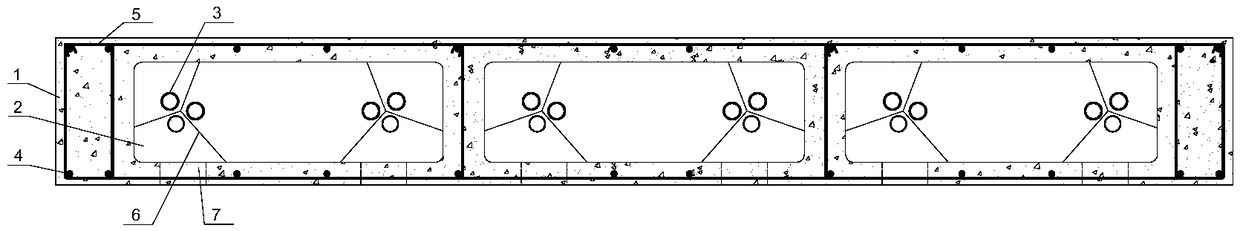

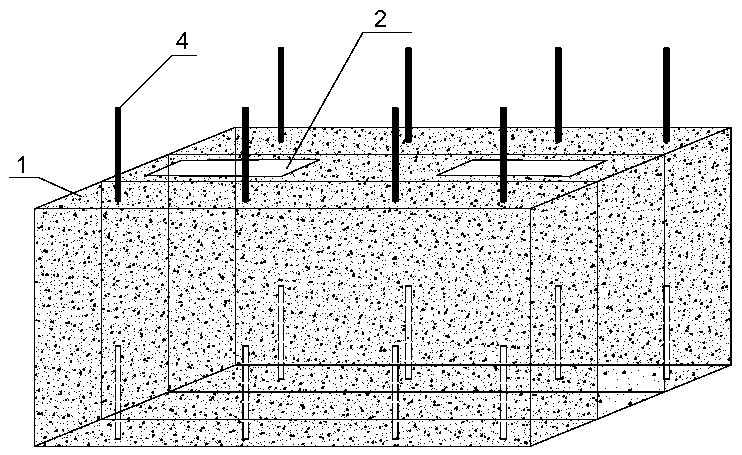

[0040] Such as figure 1 As shown, it is a prefabricated cavity type medium thin-walled concrete shear wall provided by the present invention, the cross section of the wall body 1 is rectangular; the concrete is prefabricated ordinary concrete, and the material is mainly used for the compression of components. The cavity 2 is a reserved hole, the hole is rectangular, and its cross-section is designed with a performance-based design method; the reserved hole is the middle part of the component wall section, so after the hole is reserved at this position, the impact on the structure will be reduced. The compressive capacity and the shear capacity are less affected.

[0041] As can be seen from the above examples, the section size of the thin-walled concrete shear wall in the prefabricated cavity type of the present invention, the wall thickness of the concrete, the size of the cavity 2, the area of the longitudinal reinforcement 4, the area of the stirrup 5, and the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com