Fluidizing chlorination system without sieve plate

A chlorination system without a sieve plate technology, applied in the direction of titanium tetrachloride, titanium halide, etc., to achieve the effects of improving chlorination production efficiency, facilitating the number and time of slag discharge, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

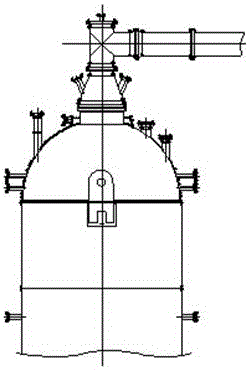

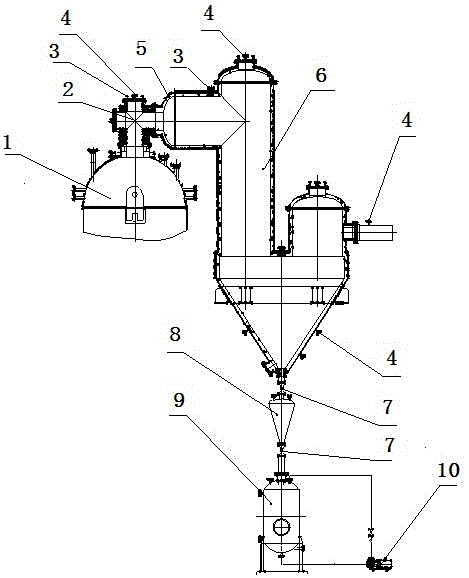

[0017] Such as figure 2 As shown, a boiling chlorination system without a sieve plate is mainly composed of a chlorination furnace 1, a double-tube dust collector 6, a cyclone dust collector and a washing device connected in sequence. The upper part of the double-tube dust collector 6 is provided with a high There are two dust collectors at the front and back stages, the conical bottom of the two dust collectors at the front and rear stages is connected to the slag collection tank 8 through the electric control valve 7, and the bottom of the slag collection tank 8 is connected to the slag collection tank through the electric control valve 7. The connection of the tank 9 is characterized in that the top of the chlorination furnace 1 is provided with a cross-shaped four-way vertical pipe short connection 2, the vertical pipe short connection 2 is connected with the double-tube dust collector 6 through the horizontal pipe short connection 5, and the horizontal pipe short connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com