An inner stator hoisting and turning structure

An inner stator and ring cage technology, which is applied to load hanging components, transportation and packaging, etc., can solve problems such as damage to inner stator products, eccentricity, and inability to turn over, so as to improve the safety factor and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more obvious and understandable, the present invention will be further described with preferred embodiments.

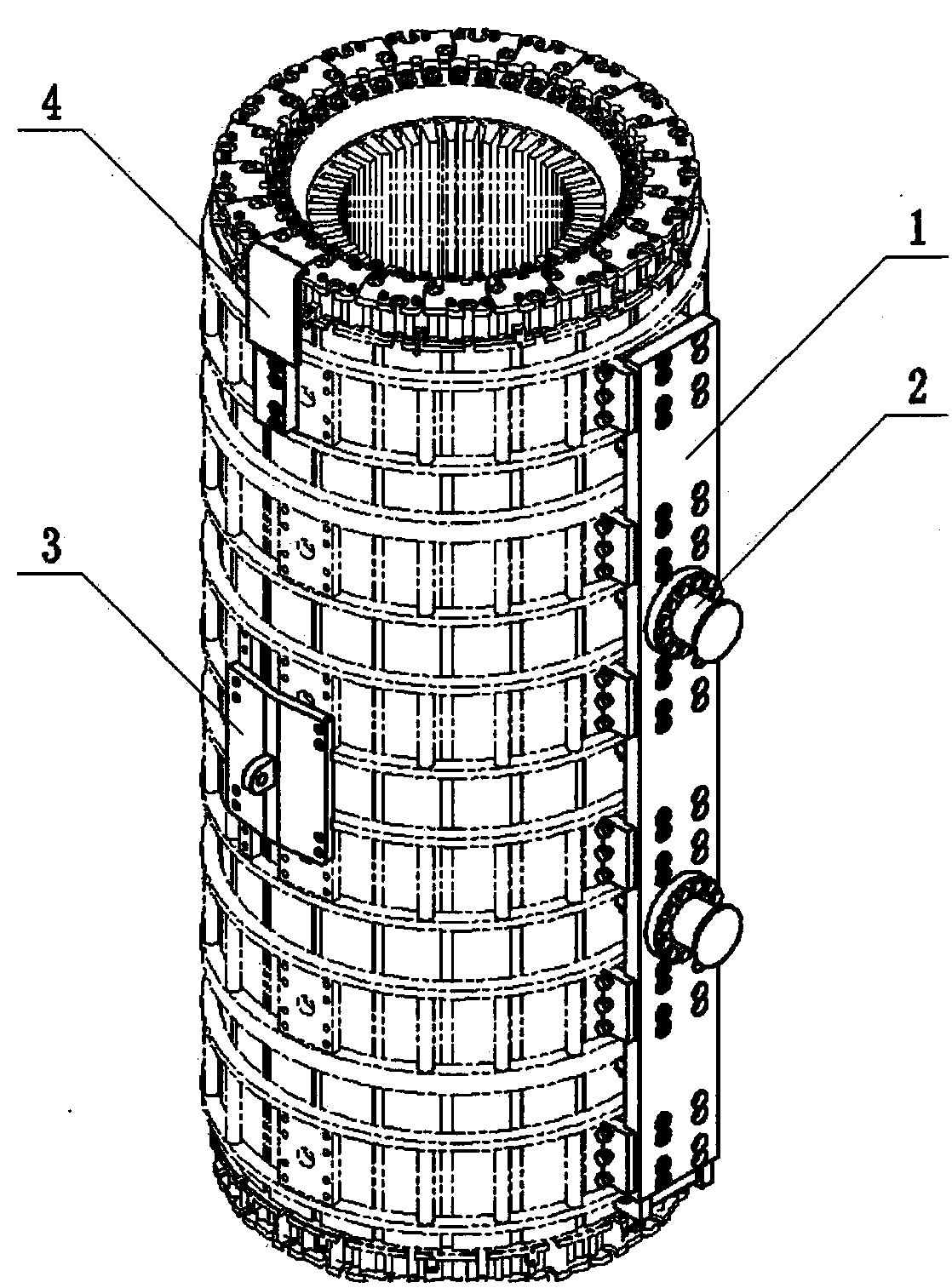

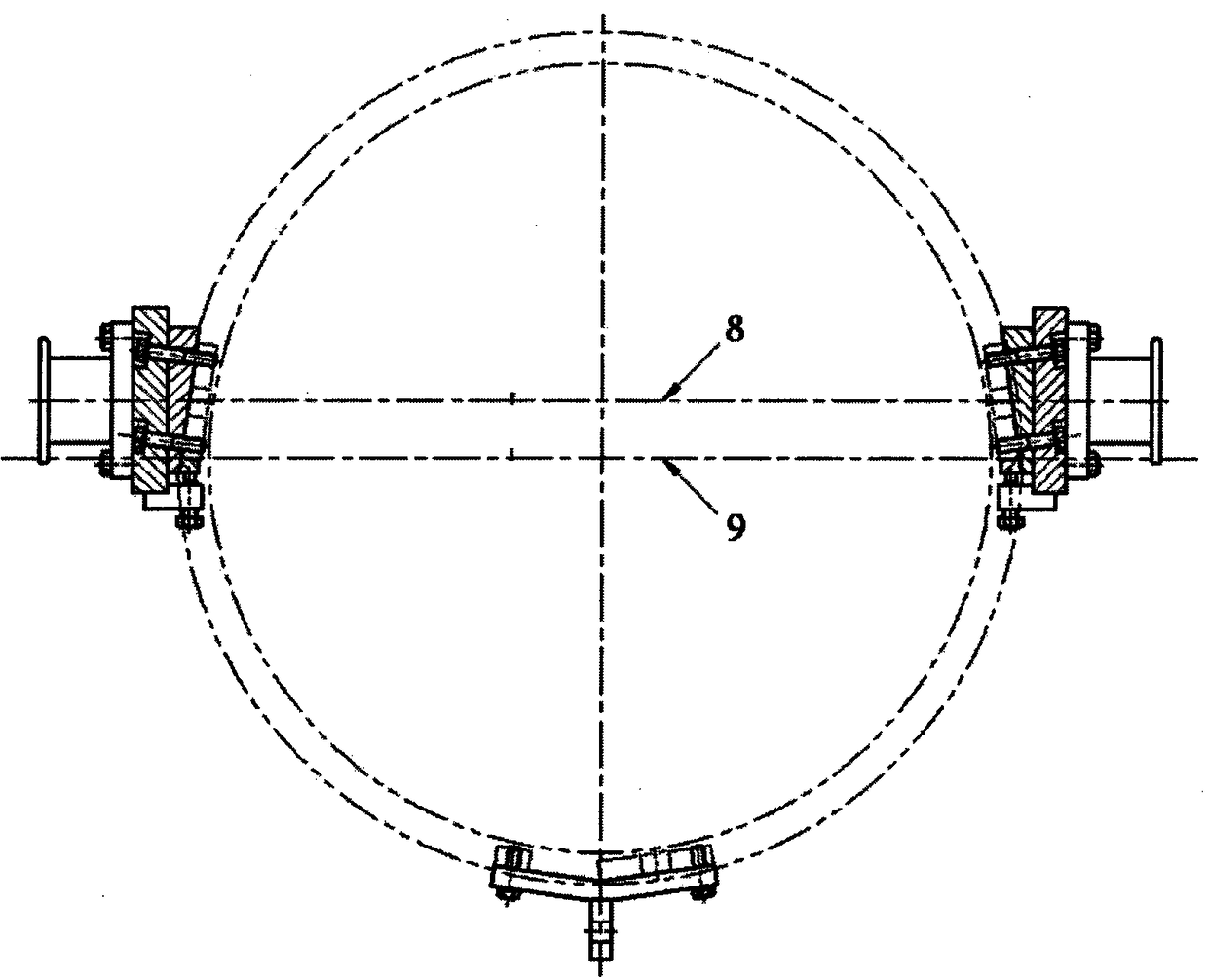

[0018] to combine figure 1 and Figure 7 , in the present invention, the inner stator has a plurality of rings 7 distributed along the axial direction, each ring 7 circles the inner stator in the circumferential direction, and a plurality of ring cage connecting plates 6 are arranged on each ring 7 in the circumferential direction.

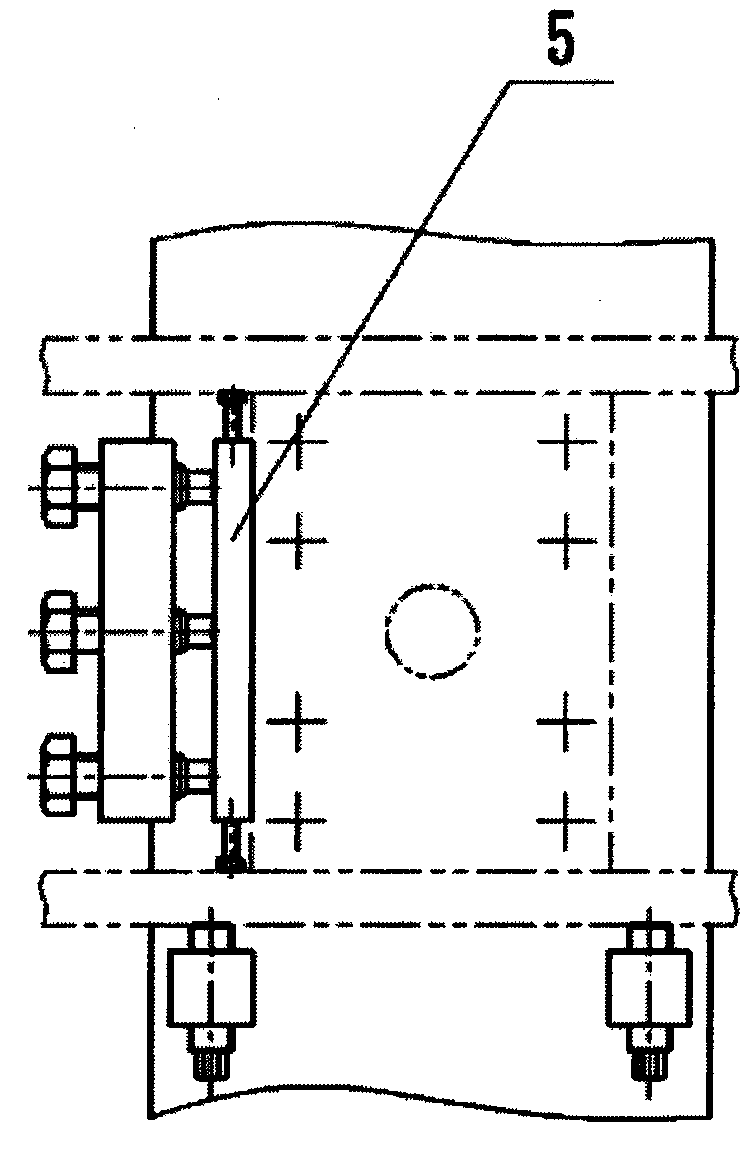

[0019] to combine figure 1 , Figure 3A and Figure 3B , An inner stator hoisting and turning structure provided by the present invention includes a ring cage connecting device 1 , a hanging climber 2 , a small hook lug 3 , a wire rope baffle plate 4 , and a spacer 5 . to combine Figure 4 and Figure 5 , The ring cage connection device 1 includes a long plate 1-1, an inclined pad 1-2, a side tightening structure 1-3 and a tightening structure 1-4.

[0020] The structure of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com