Wheel pair axle box device enabling rotating speed of left wheel and that of right wheel of low floor light rail bogie to be synchronous

A wheel speed and bogie technology is applied in the field of non-power bogies of low-floor light rail vehicles to achieve the effects of increasing service life, reducing eccentric wear of wheel rims, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

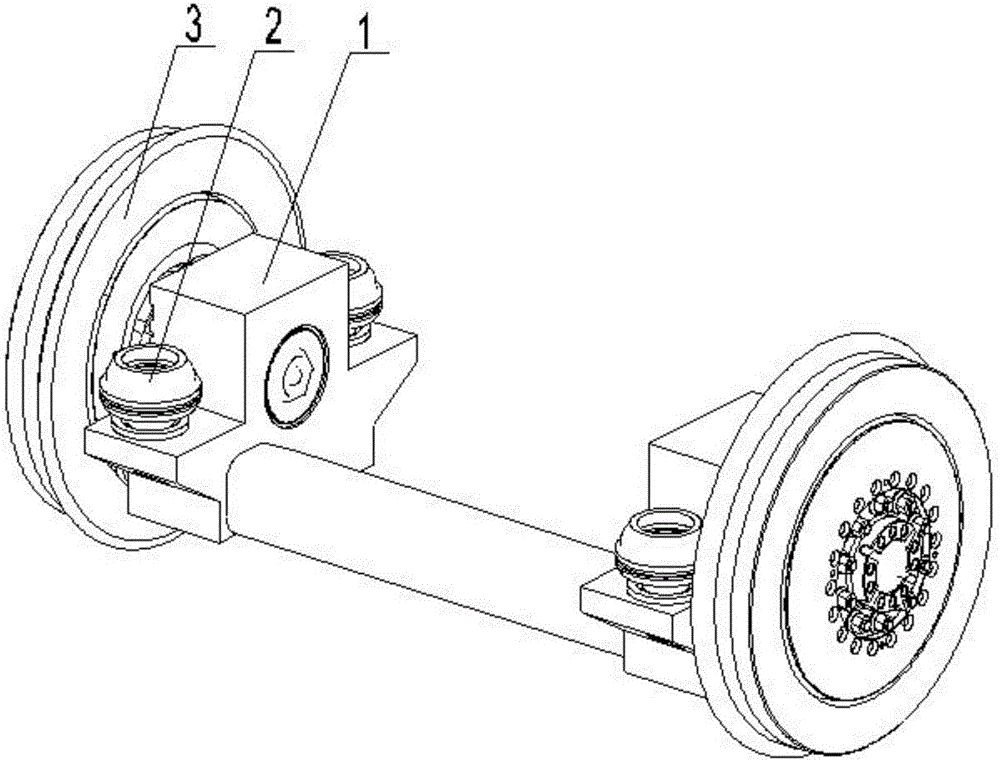

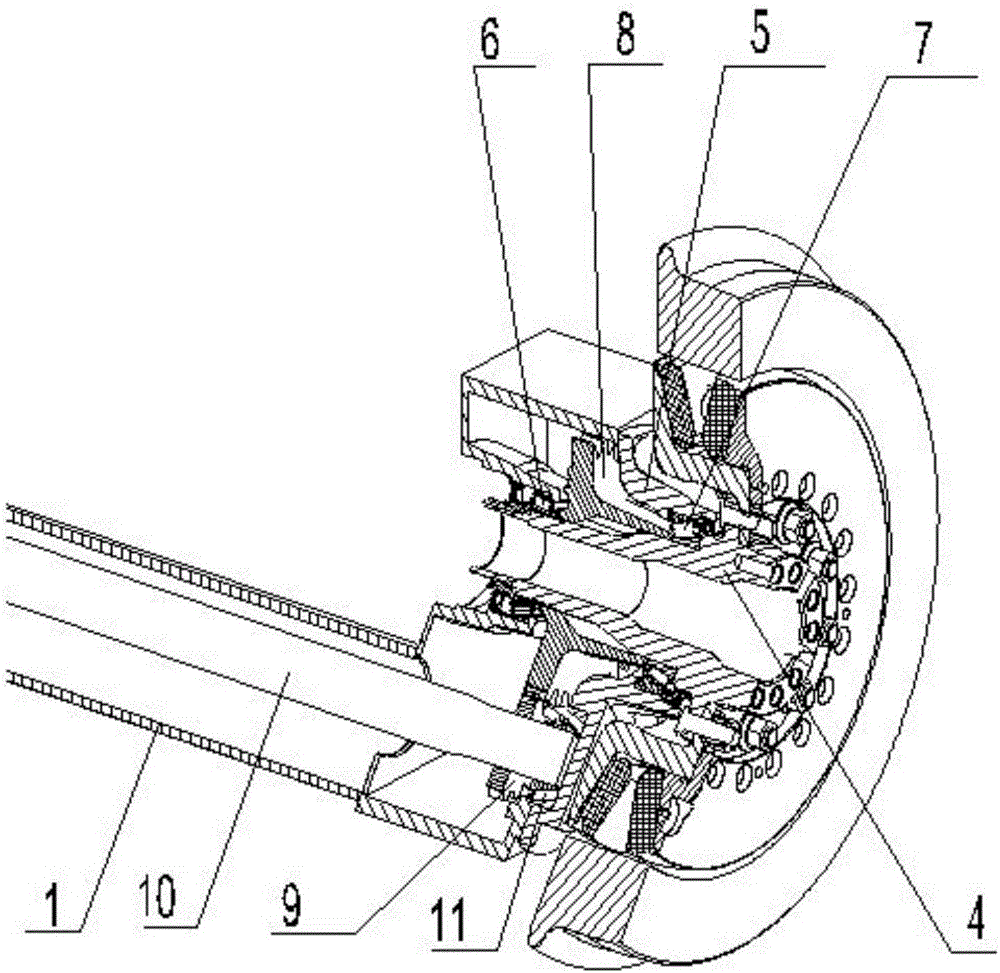

[0013] Reference figure 1 , figure 2 , The wheel set axle box device consists of axle bridge 1, primary spring 2, elastic wheel 3, axle 4, flange connection seat 5, fixed axle bearing 6, fixed axle bearing 7, transmission gear 8, transmission pinion 9 , The drive shaft 10 and the bearing 11 that fix the drive shaft are composed. The elastic wheel 3 is connected to the axle 4 by flange surface fasteners, and the axle 4 is fixed by the bearing 6 installed in the axle axle 1 and the bearing 7 in the flange connecting seat 5. Axle and axle 1 is a one-piece casting structure, with a hollow axle body in the middle and hollow axle boxes on both sides, which are completely penetrated from left to right. It is the main bearing structure of the wheel set axle box device. A fixed axle bearing 6 and fixed are arranged inside the axle box axle bridge. The mounting seat of the drive shaft bearing 11 is provided with a mounting interface for fixing the flange connection seat 5 of the axle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com