Sorting system having cover plates closing gaps between support structures

A support structure and sorting system technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of increasing the cost of the sorting system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

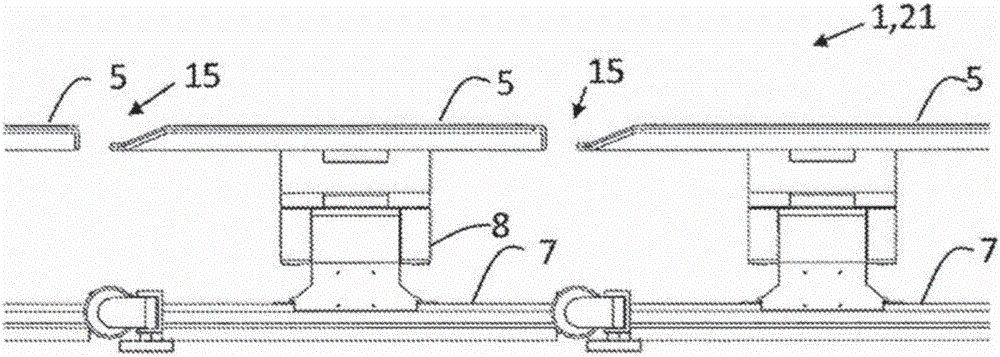

[0124] Figures 1 to 3 all illustrate the prior art. FIG. 1 shows elements of a sorting system 1 with a carrier 21 with a trolley 7 . A cart 7 supports a tilt mechanism 8 and a support structure 5 . The carts 7 are strung together to form a chain of carts. The clearance 15 is normal for the transport of unsloped or inclined support structures in the arcuate sections of the track, not shown.

[0125] In FIG. 2 support structures 5 are shown, one of which has a protruding end 16 and is at a distance to the adjacent support structure, whereby a gap 15 is created.

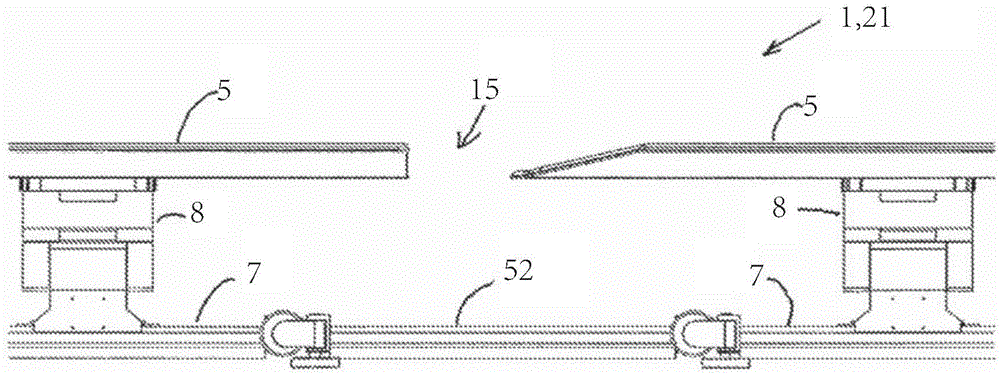

[0126] FIG. 3 shows elements of a sorting system 1 with a carrier 21 with a trolley 7 , a support tilt mechanism 8 and a support structure 5 . The carts 7 are connected in series. The clearance 15 is normal for transporting inclined or non-inclined support structures in arcuate sections of the track not shown. In the case shown, the support structure 5 is longer than the trolleys 7 , so the intermediate trolley 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com