Establishment method and application of a three-parameter gas well drainage and gas recovery process optimization model

A drainage gas recovery and establishment method technology, which is applied in the field of establishment of gas well drainage gas recovery process optimization model, can solve the problems of early decline period, lower recovery rate, rapid decline of gas production, etc., and achieve the effect of rapid determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a method for establishing a three-parameter gas well drainage and gas recovery process optimization model, the method includes the following steps:

[0026] a. Collect the production parameters of water-producing gas wells in the gas field block, including: daily gas production 0~4×10 4 m 3 , gas-water ratio 0~100m 3 / 10 4 m 3 , tubing inner diameter 4.0 inches, 3.5 inches, 3.0 inches, 2.5 inches, 2.0 inches, 1.5 inches, air-water interfacial tension is 60 mN / m, formation water density 1.01 kg / m 3 , natural gas density 0.58 kg / m 3 , deep is 2000~4000 m, formation pressure 2.5~8.1 MPa, wellhead pressure 2.5~4.1 MPa, bottom hole temperature 80~130 ℃;

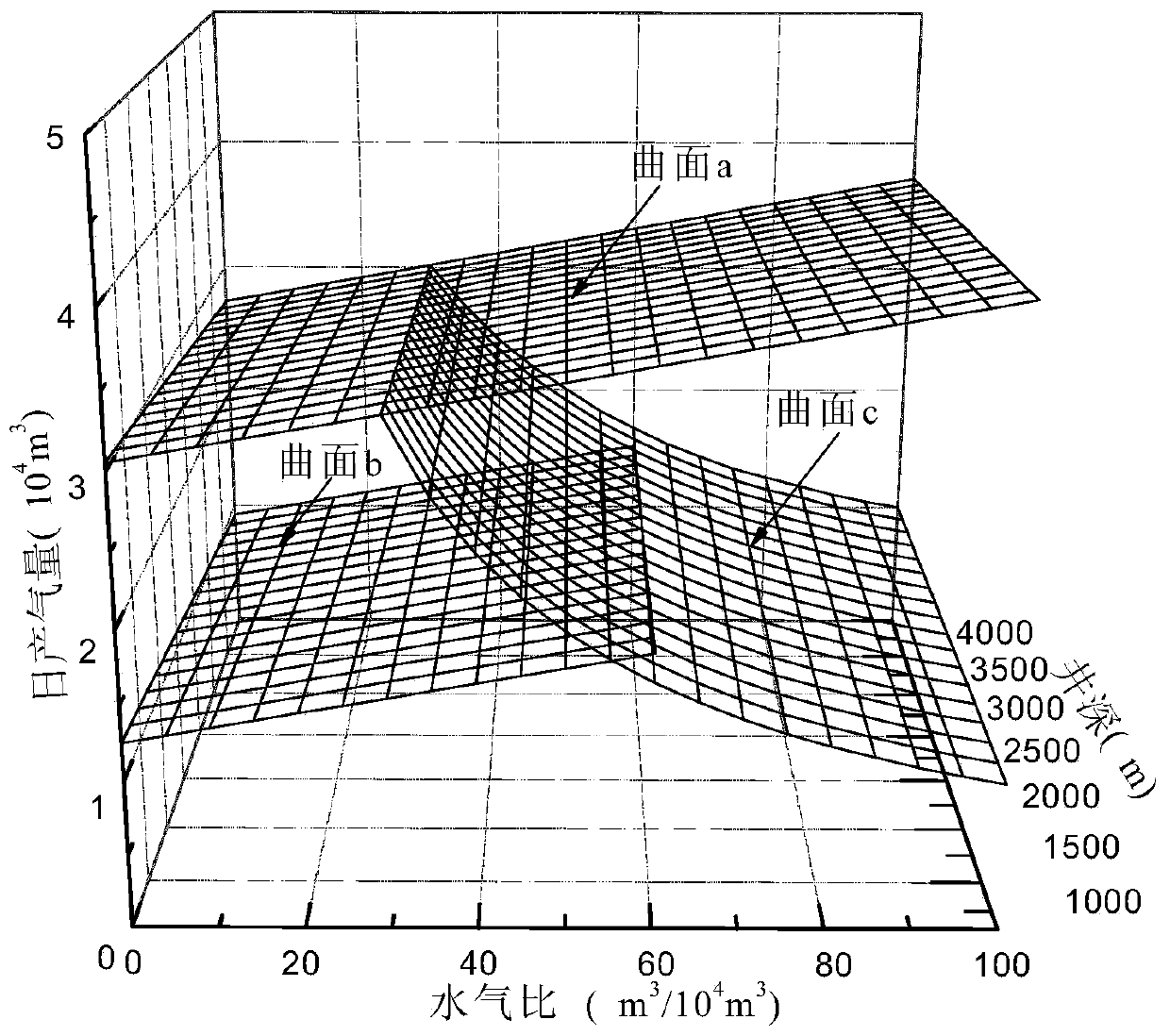

[0027] b. In the range of well depth 2000-4000 m, calculate the critical liquid-carrying flow rate of natural gas under different daily gas production and water-gas ratio of a given tubing diameter, and choose the following one for the calculation model of critical liquid-carrying flo...

Embodiment 2

[0038] Embodiment 2, a method for establishing a three-parameter gas well drainage and gas recovery process optimization model, the method includes the following steps:

[0039] a. Collect the production parameters of water-producing gas wells in the gas field block, including: daily gas production 0~6×10 4 m 3 , gas-water ratio 0~100m 3 / 10 4 m 3 , tubing inner diameter 3.5 inches, 3.0 inches, 2.5 inches, 2.0 inches, 1.5 inches, air-water interfacial tension is 60 mN / m, formation water density 1.01 kg / m 3 , natural gas density 0.58 kg / m 3 , deep 1800~3200m, formation pressure 2.5~8.1 MPa, wellhead pressure 4.5~6.1MPa, bottom hole temperature 90~135℃;

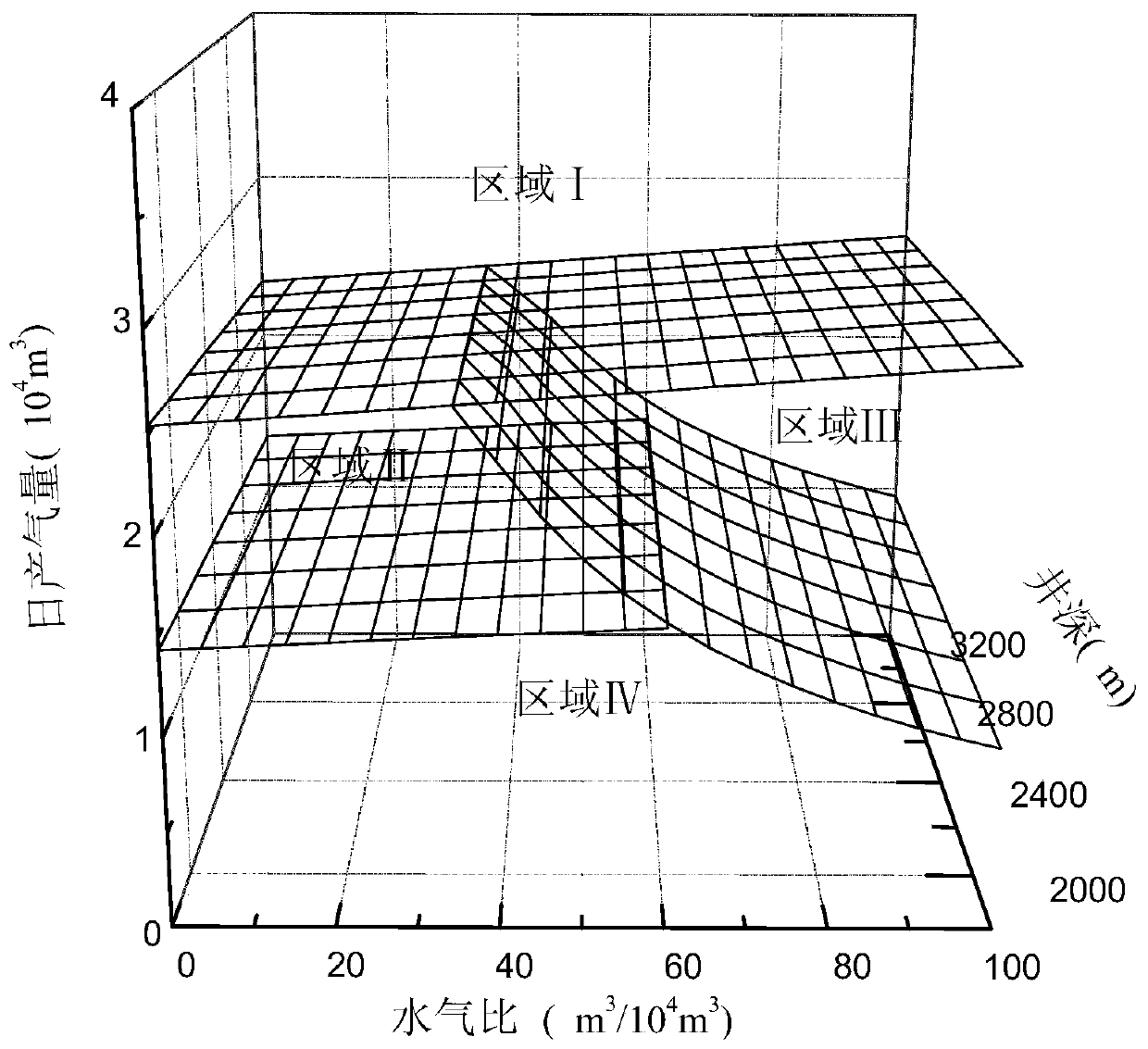

[0040] b. In the range of well depth 1800-3200m, calculate the critical liquid-carrying flow rate of natural gas under different daily gas production and water-gas ratio of a given tubing diameter, and choose the following one for the calculation model of critical liquid-carrying flow rate of natural g...

Embodiment 3

[0045] Embodiment 3, the application of a three-parameter gas well drainage and gas recovery process optimization model, the application steps are as follows:

[0046] a'. Collect parameters of water-producing gas wells in the gas field block; gas production on June 15, 2015 was 3.8×10 4 m 3 , water-air ratio 15m 3 / 10 4 m 3 , The depth of gas well A is 2900m;

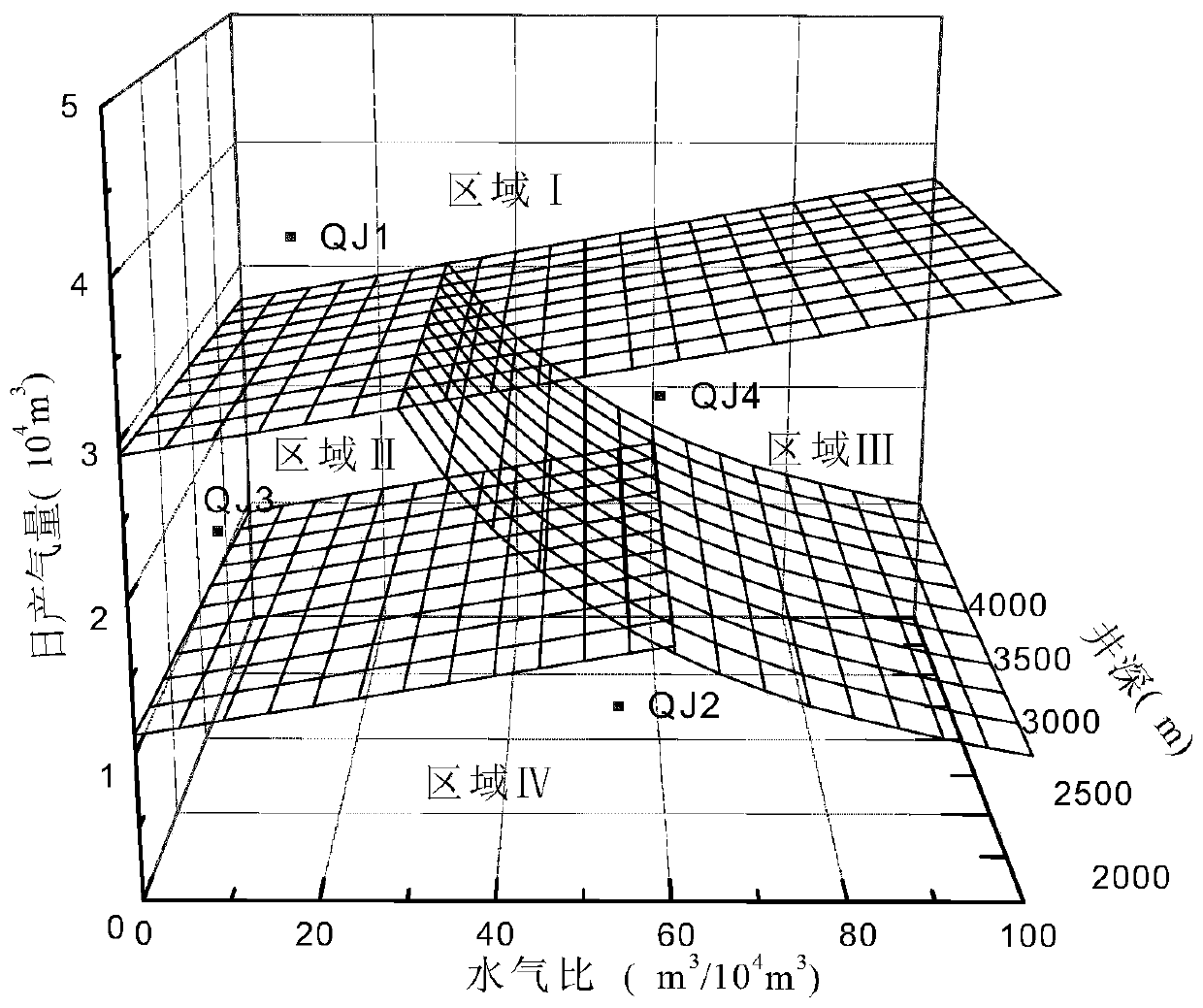

[0047] b', combine figure 2 It can be seen that the gas well A located in area I can normally carry liquid and produce without any drainage and gas recovery process. Gas production on July 15, 2015: 3.0×10 4 m 3 , water vapor ratio 20m 3 / 10 4 m 3 . combine image 3 It can be seen that the gas well A is located in area II, and adopts one or two drainage gas recovery techniques of the preferred pipe string or foam;

[0048] c'. Prediction and optimization of pipe string drainage gas recovery process during one year of natural gas production increase Q=36×10 4 m 3 , natural gas price J=1.978 yuan / m 3 , i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com