Design method of variable inlet guide vane, and blade and compressor

A technology of guide vanes and design methods, applied in the field of compressors, can solve problems such as the range of available angles of attack of advanced aero-engines, and achieve the effect of meeting the requirements of structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

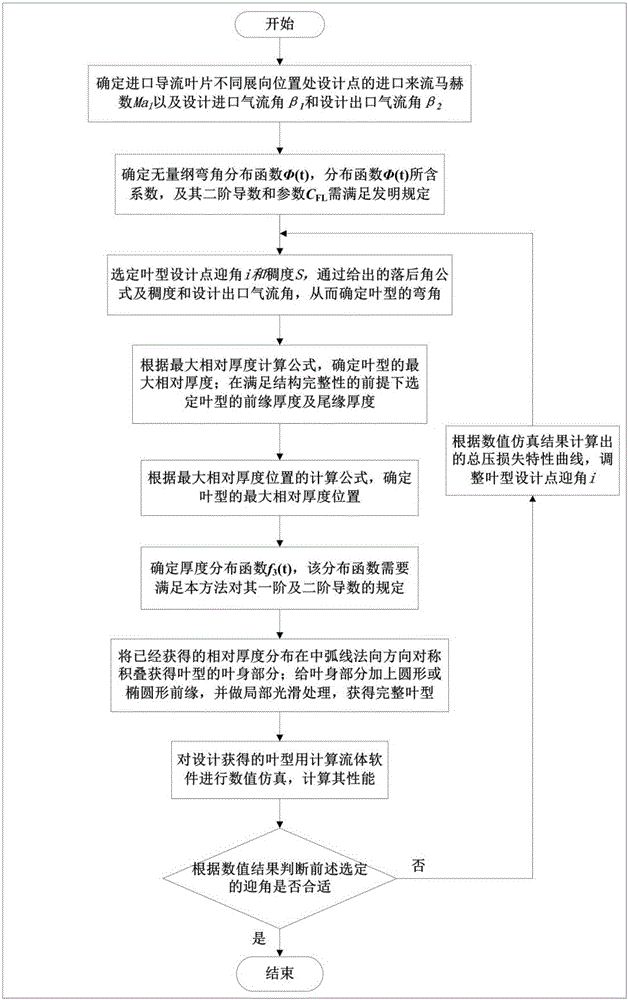

[0062] figure 1 The design flow chart of the variable inlet guide vane according to the present invention is shown. Such as figure 1 Shown, the design method of the variable inlet guide vane of the present invention, it comprises the following steps:

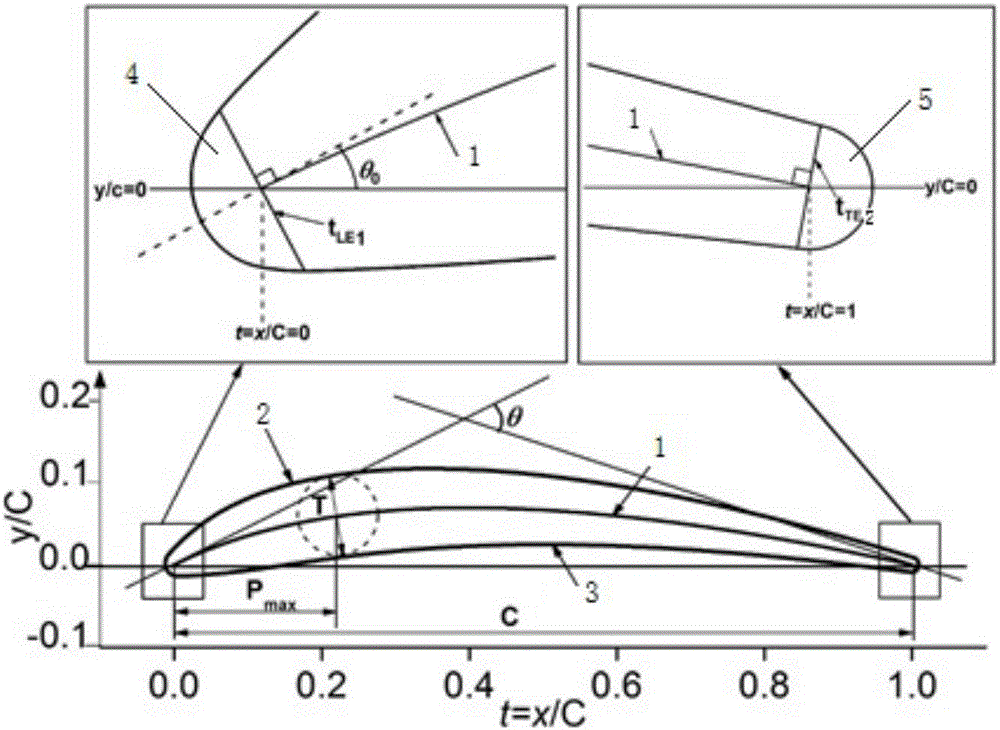

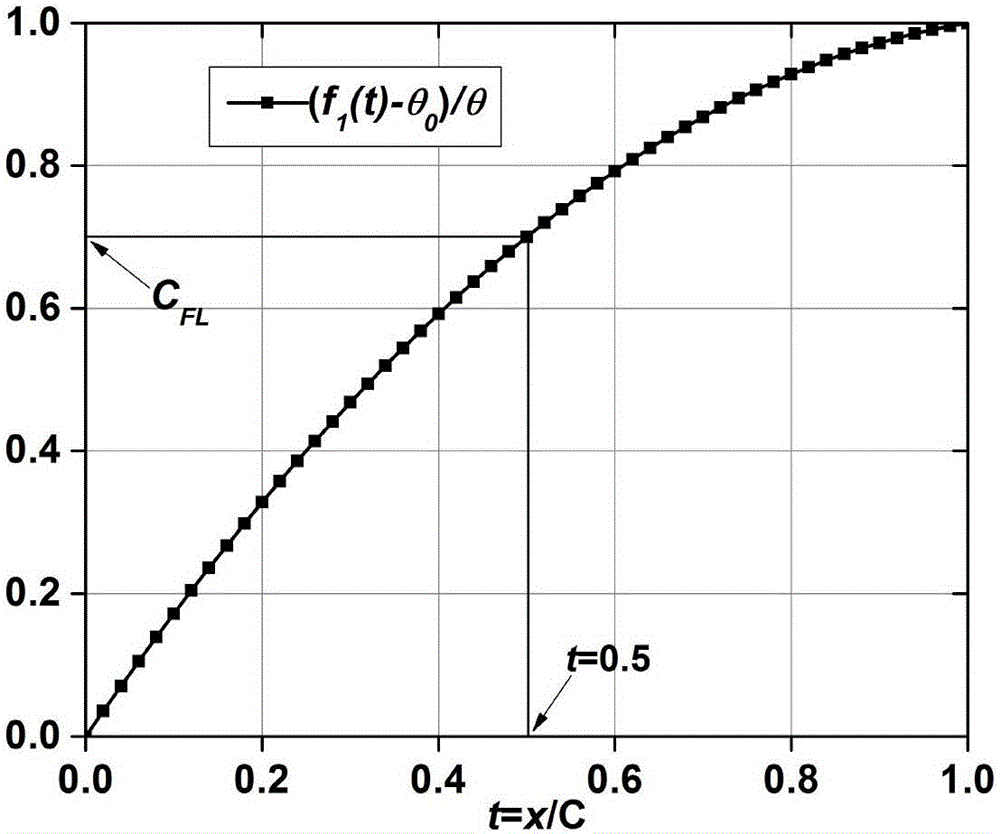

[0063] S1: Determine the inlet and incoming flow Mach number M at the design point at different spanwise positions of the inlet guide vanes a1 and the design inlet airflow angle β 1 and design outlet airflow angle β 2 , this step can be accomplished through conventional compressor flow design procedures. The consistency S of the primitive airfoil at the spanwise position can be determined from the flow-through results,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com