Wall starching and plastering robot

A robot and mortar technology, applied in construction, building construction, etc., can solve the problems of long time, high cost, low efficiency of small area operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

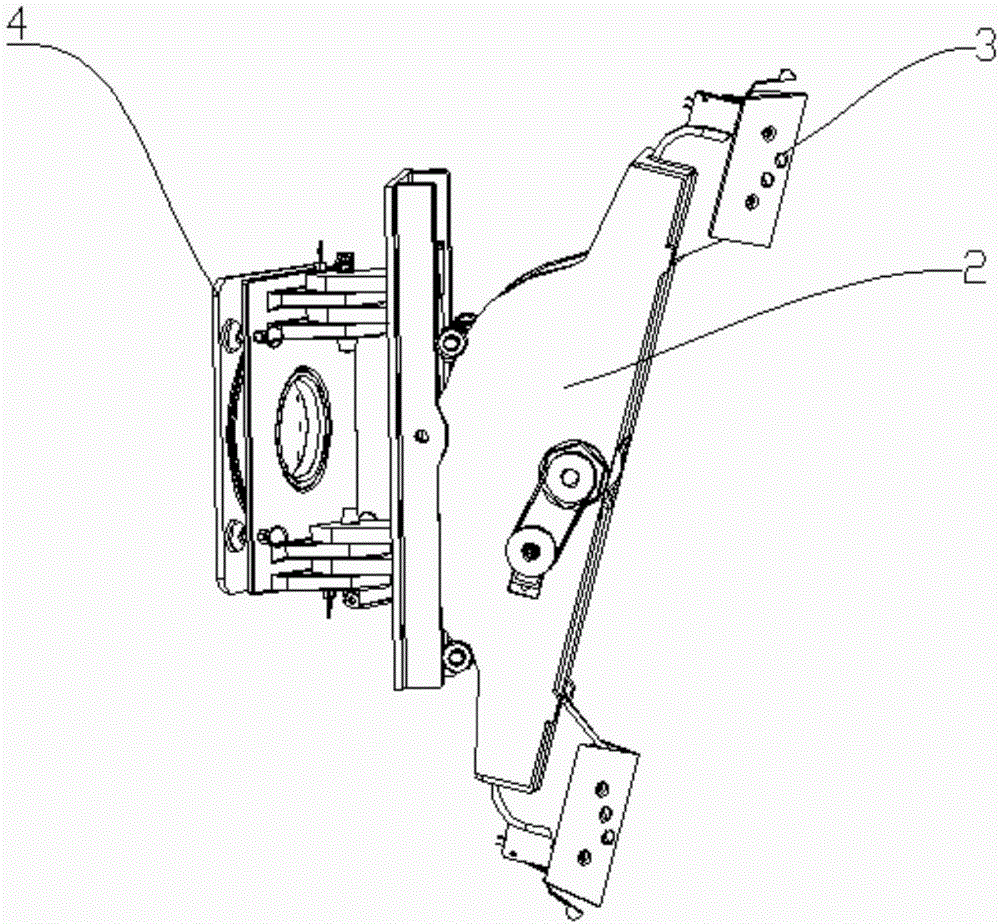

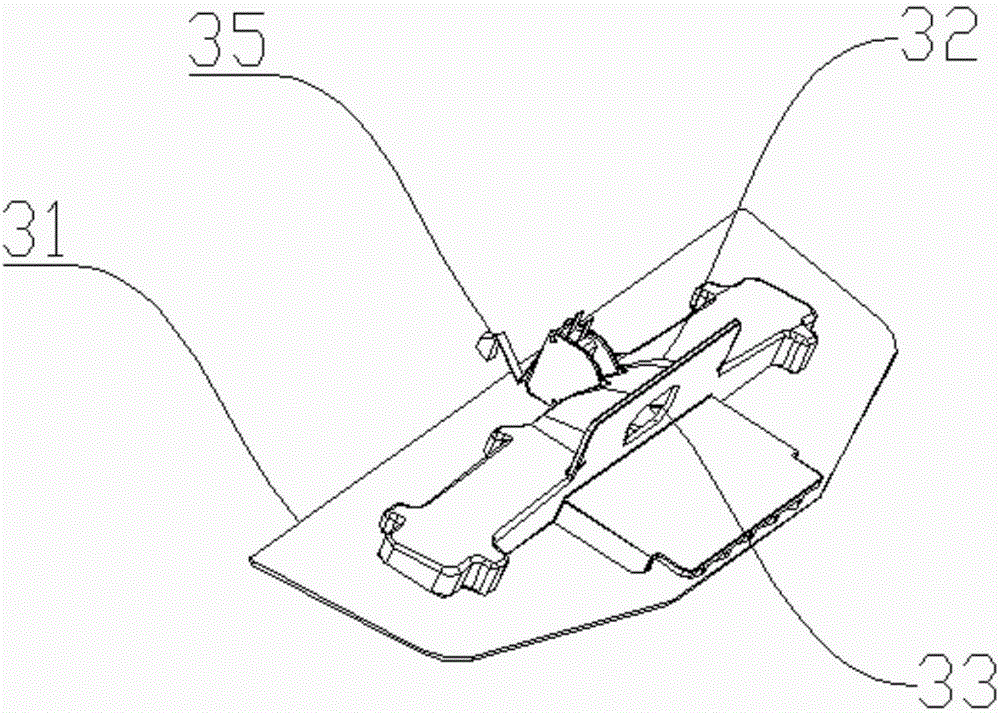

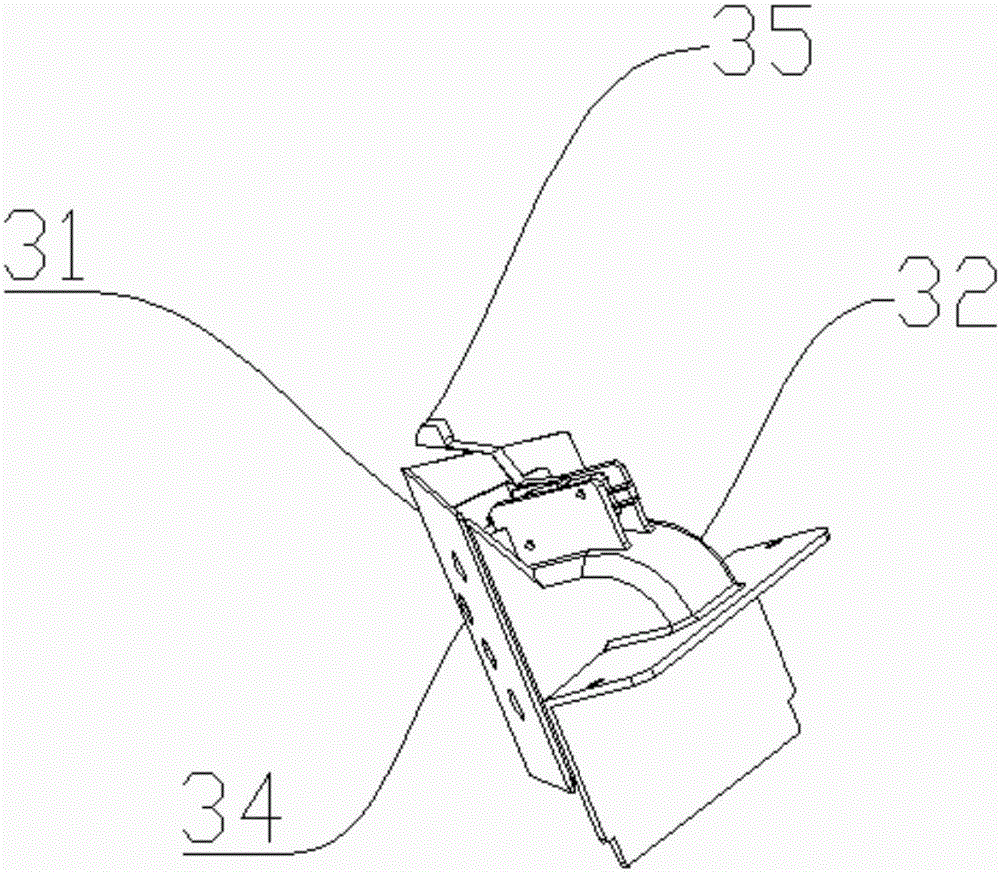

[0054] Such as figure 1 with image 3 As shown, in one embodiment of the present invention, the wall surface scraping and plastering operation device includes a rotary table 4, a turning table 2 and a scraping head 3; the rotary table 4 includes a mounting connection seat 41 , the rotating device 42 and the rotating platform, the installation connection seat 41 is connected with the rotating platform through the rotating device 42; Squeegee working head 3 is installed. In this embodiment, the two ends of the turning table 2 are respectively connected with one image 3 The scraping head 3 shown is the scraping head; the scraping head 3 includes a scraper 31 and a mortar chamber cover 32, the scraper 31 is installed on the mortar chamber cover 32, and the mortar chamber A mortar inlet 33 is opened on the cover 32 ; a number of mortar outlets 34 are opened on the scraper 31 . Mortar outlet 34 discharges slurry, and the mortar after the slurry discharge is directly on the scra...

Embodiment 2

[0058] On the basis of Embodiment 1, there is only one squeegee working head 3 , and the squeegee working head 3 is a flat plate similar to the artificial wall surface squeegee, and the back of the flat plate is connected to the turning table 2 . The flat plate covers the end face of the entire turning table 2 away from the hinged end. The hinged turning feature of the turning table 2 can make the flat plate form a certain angle with the wall, which is the same as the reason that the operator's squeegee also has a certain angle with the wall during manual squeegeeing; the squeegee can be realized.

[0059] From Embodiment 1 and Embodiment 2, it can be found that the position of the scraping head 3 on the turning table 2 is not strictly required; Squeegee, the choice of its shape can also be changed according to the shape of the area to be constructed. The rotation of the rotary table 4 can drive the squeegee working head 3 to rotate, so that a set of devices can realize the p...

Embodiment 3

[0061] Such as figure 2 Shown, on the basis of embodiment 1, described squeegee working head 3 is a scraping work head, and described scraper 31 is flat plate; Offers some mortar outlets 34 on described flat plate, and mortar is from mortar The inlet 33 enters the mortar chamber cover 32, and then the slurry is discharged from the mortar outlet 34 and located on the scraper 31, and the scraper 31 can directly scrape the slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com