A kind of composite plasticizer and preparation method for htpb-based explosives and propellants

A composite plasticizer and propellant technology, which is applied to non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve the problems of dissent, large energy consumption and time consumption, and achieve short time consumption and solid content of explosives High, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

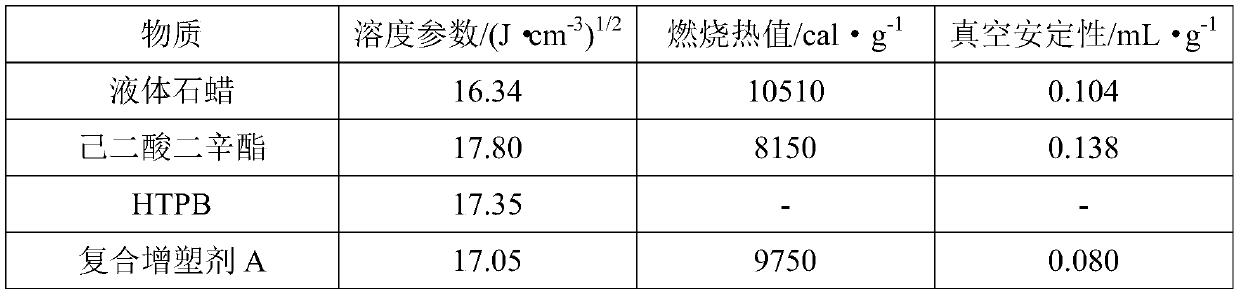

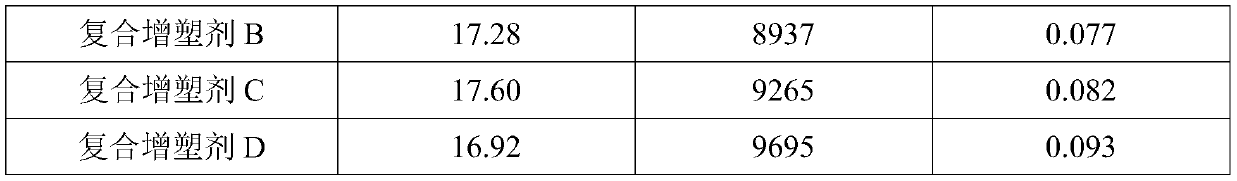

[0019] According to a second aspect of the present invention, the present invention provides a method for preparing a composite plasticizer for HTPB-based explosives and propellants, the method comprising: dioctyl adipate and liquid paraffin are heated and rotated under reduced pressure Steam processing, obtain described composite plasticizer;

[0020] Wherein, based on the total weight of the composite plasticizer, the content of the dioctyl adipate is 1-99% by weight, and the content of the liquid paraffin is 1-99% by weight.

[0021] Preferably, based on the total weight of the composite plasticizer, the content of the dioctyl adipate is 20-80% by weight, and the content of the liquid paraffin is 20-80% by weight.

[0022] In addition, the specific elaboration and preferred conditions of the liquid paraffin are the same as those described above, and will not be repeated here.

[0023] In the present invention, the decompressed heating and rotary evaporation treatment can b...

Embodiment approach

[0024] According to a preferred embodiment, the preparation method of the present invention specifically includes the following steps:

[0025] 1) vacuuming: sealing dioctyl adipate and liquid paraffin in a rotary steamer, and vacuuming;

[0026] 2) Rotary evaporation treatment: the dioctyl adipate and liquid paraffin are subjected to rotary evaporation at 50-100°C.

[0027] In step 1), the vacuum is such that the vacuum degree of the rotary evaporator can be -0.1 to 0 MPa, and the purpose is to completely remove the air in the rotary evaporator.

[0028] In step 2), the temperature of the rotary steaming treatment is preferably 75-95°C.

[0029] In step 2), the rotational speed of the rotary steaming treatment may be 10-100 rpm, preferably 30-70 rpm.

[0030] In step 2), the time for the rotary steaming treatment may be 1-4 hours, preferably 2-3 hours.

[0031] According to the third aspect of the present invention, the present invention provides a composite plasticizer pr...

Embodiment 1

[0043] This example is used to illustrate the composite plasticizer and preparation method for HTPB-based explosives and propellants of the present invention.

[0044] The composite plasticizer contains dioctyl adipate and liquid paraffin; based on the total weight of the composite plasticizer, the content of dioctyl adipate is 33% by weight, and the content of liquid paraffin is 67% by weight .

[0045] The above-mentioned composite plasticizer is prepared through the following specific operations:

[0046] Step 1: Seal dioctyl adipate and liquid paraffin in a rotary evaporator, and use a vacuum pump to depressurize the rotary evaporator to -0.1MPa;

[0047] Step 2: Heating the temperature to 90° C., adjusting the rotary steaming speed to 50 rpm, and rotary steaming for 2 hours, so as to obtain the composite plasticizer A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com