Piezoelectric drive amplification mechanism and its design method for micro flapping rotor aircraft

A technology of amplifying mechanism and piezoelectric drive, applied in aircraft, design optimization/simulation, CAD based on constraints, etc., can solve the problems of small output displacement of piezoelectric drive, large space volume, small magnification, etc., to achieve small size, The structure is simple and the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

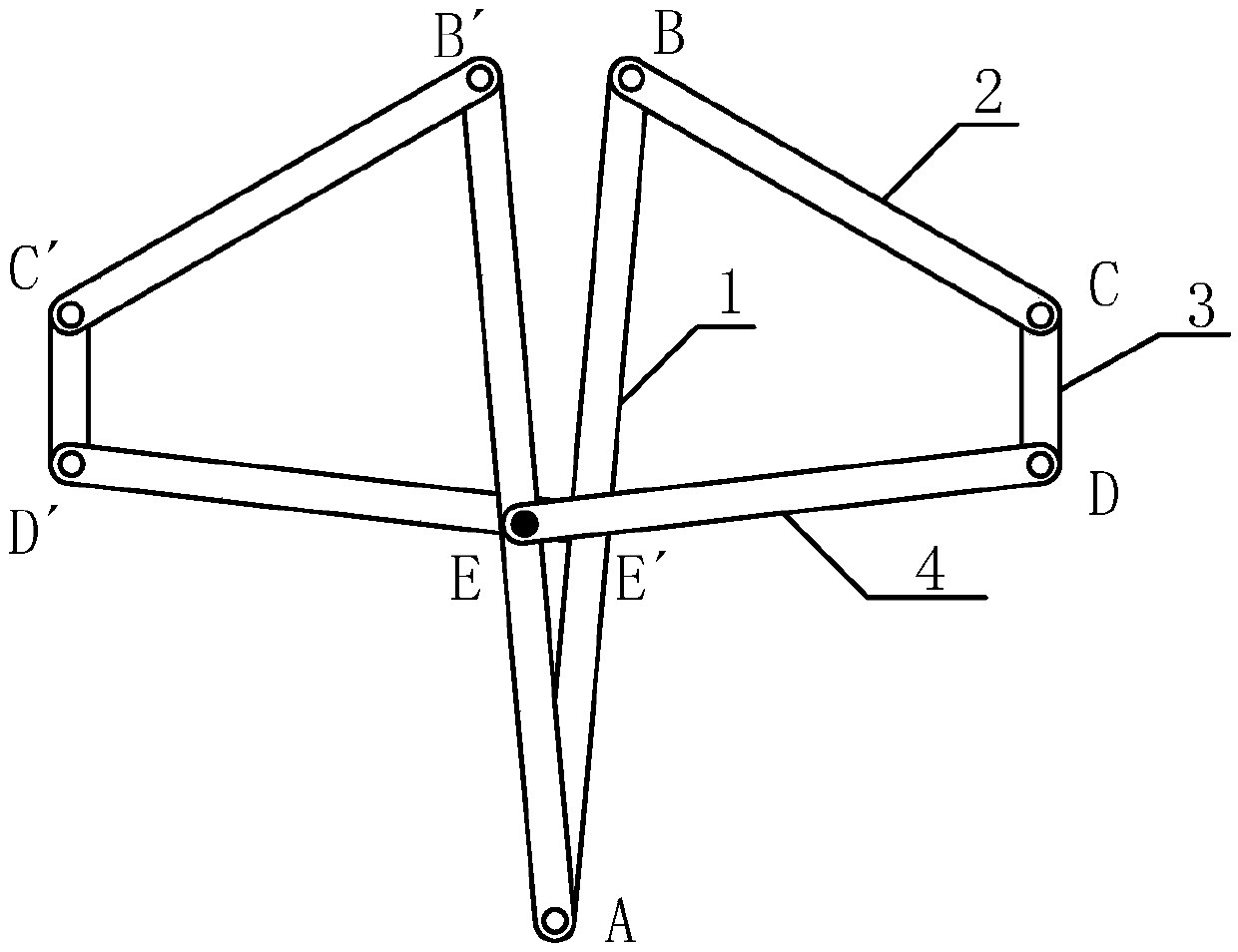

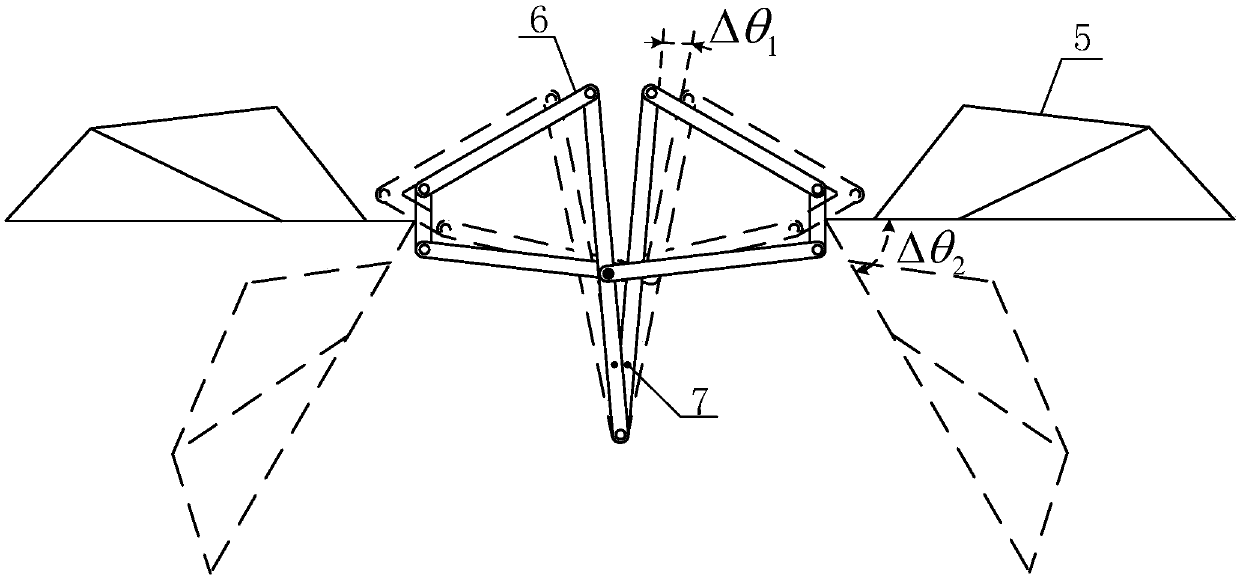

[0051] Such as figure 1 As shown, a piezoelectric drive amplification mechanism for a miniature flapping rotor aircraft is composed of two sets of symmetrical crank-rocker mechanisms ABCDE and A′B′C′D′E′. These two groups of four-bar mechanisms The structure and size of each component are exactly the same. The main components of the mechanism include rockers AB and A′B′, connecting rods BC and B′C′, cranks CD and C′D′, connecting rods DE and D′E′, forming two sets of left and right crank-rocker mechanisms, of which The rocker AB is connected to the connecting rod BC by a smooth hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com