A method for longitudinal arrangement of temporary bracing for horizontal block construction of steel box girder

A longitudinally arranged, steel box girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of insignificant improvement in deformation and stress, and low reinforcement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

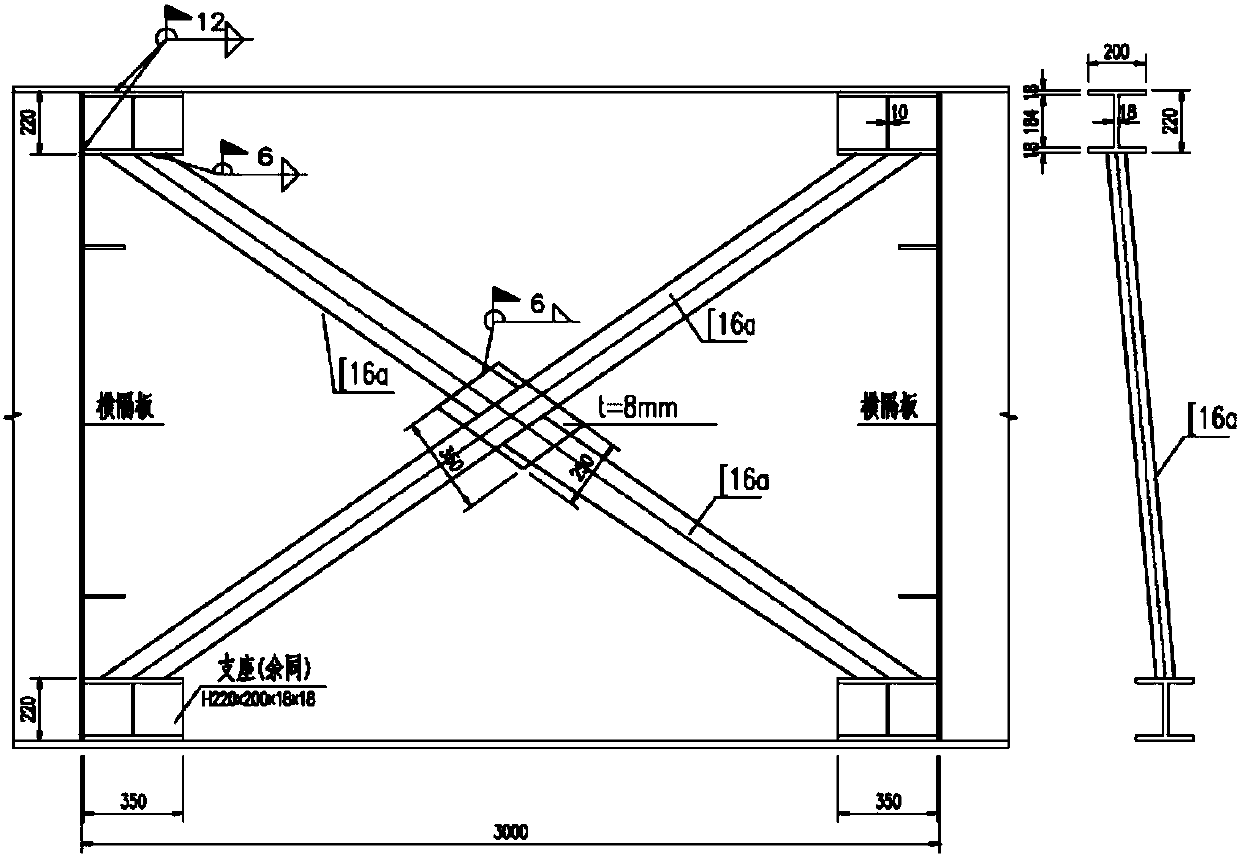

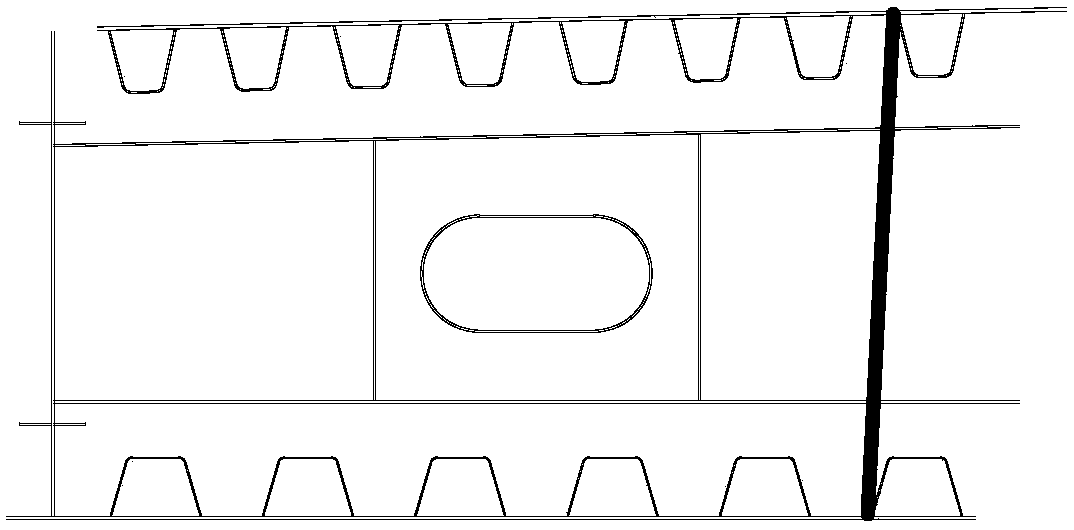

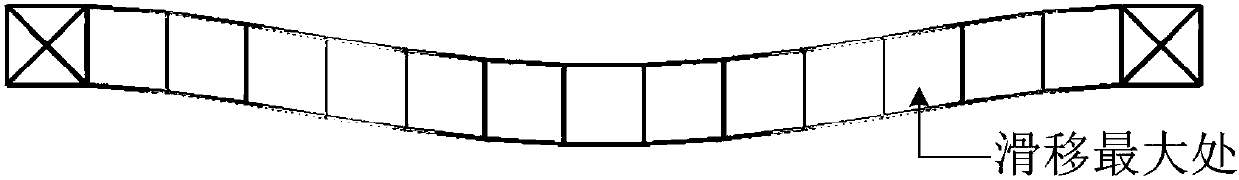

[0012] Such as figure 1 As shown, the temporary support form is X-shaped scissors, and the fulcrum of the scissors is set at the junction of the diaphragm and the top and bottom plates; figure 2 As shown, the transverse bridge support is separated by a longitudinal rib at the opening side of the beam block missing web; the longitudinal bridge layout method is as follows: Figure 3-1 As shown, first, two temporary scissor braces are arranged at the two ends of the opening side respectively, and then the modeling analysis is carried out to compare the slippage of the top and bottom plates; as Figure 3-2 As shown in , place the other two temporary scissors at the place with the largest slip, conduct modeling analysis again, compare the slip of the top and bottom plates, and set up temporary scissors at the place with the largest slip; and so on until the deformation satisfies Welding requirements. The temporary scissors bracing is arranged in the transverse direction of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com