Anilox roller transmission mechanism of printing machine

A technology of transmission mechanism and anilox roller, which is applied in the direction of printing machines, general parts of printing machinery, printing, etc., can solve the problems that the double-sided printing on the front of the substrate cannot be applied, and achieve the effect of highlighting the substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

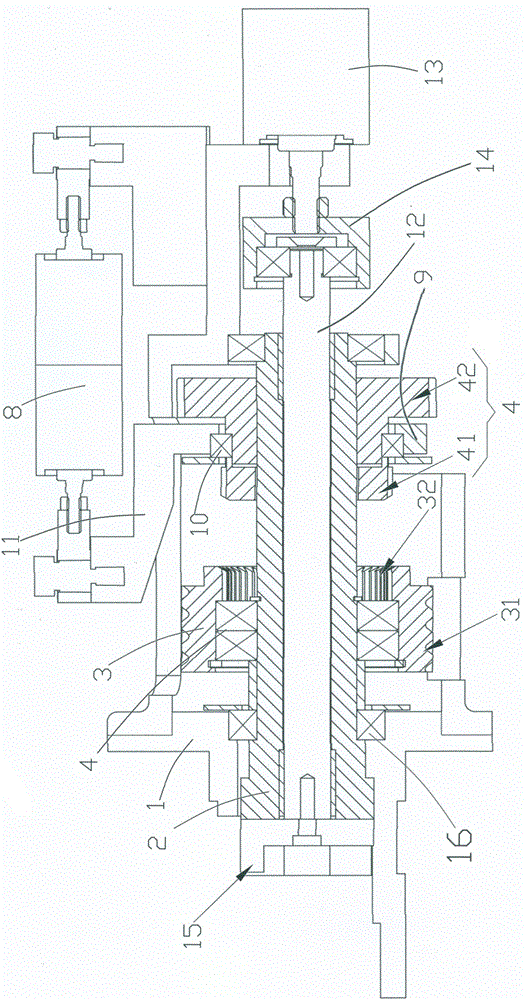

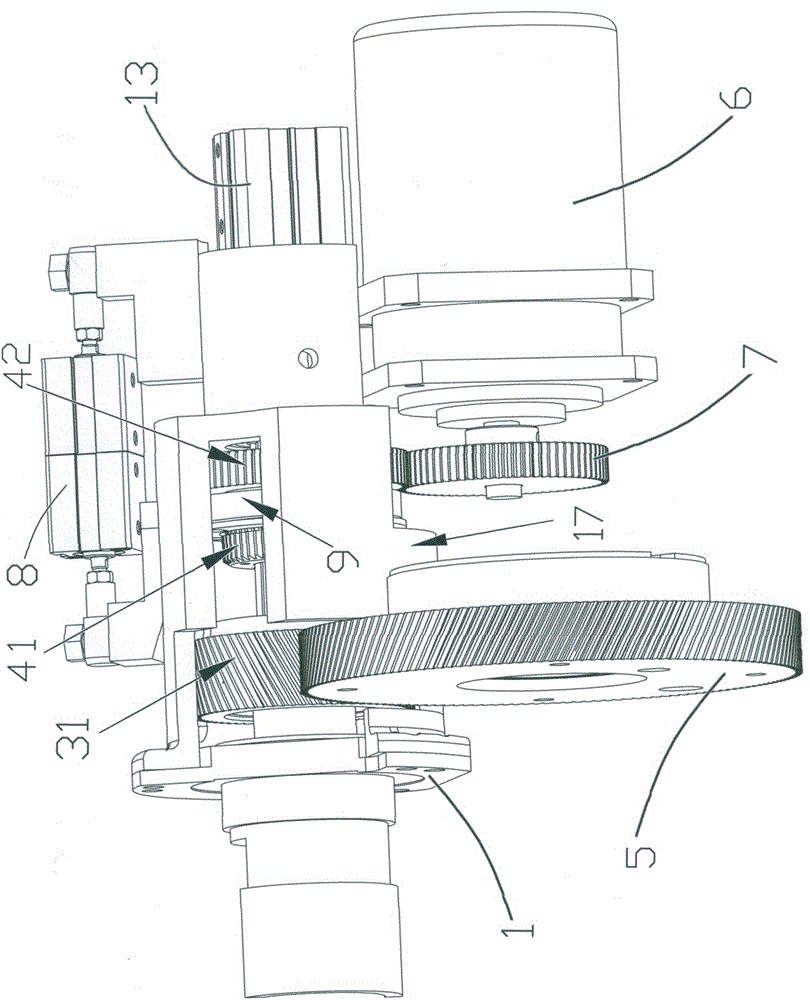

[0022] Referring to the accompanying drawings, the anilox roller transmission mechanism of the printing machine in this embodiment includes a mounting seat 1 and a transmission shaft 2 . The transmission shaft 2 is connected to the transmission of the anilox roller, and the transmission shaft 2 can drive the anilox roller to rotate.

[0023] Transmission shaft 2 is provided with positive and negative two-way rotation on mounting seat 1, and bidirectional rotating bearing 16 (adopting rolling bearing) can be set between transmission shaft 2 and mounting seat 1, so that rotate smoothly.

[0024] The transmission shaft 2 is connected with the first gear assembly 3 and the second gear assembly 4 .

[0025] The first gear assembly 3 has a first tooth portion 31 and a second tooth portion 32 . In this embodiment, as a preference, the first tooth portion 31 of the first gear assembly 3 is an outer ring gear, the second tooth portion 32 is an inner ring gear, and the first gear assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com