Multi-plate splicing welding tooling

A technology for welding tooling and horizontal plates, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of depression, discontinuity of welding seam, and inability to position the cuboid frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

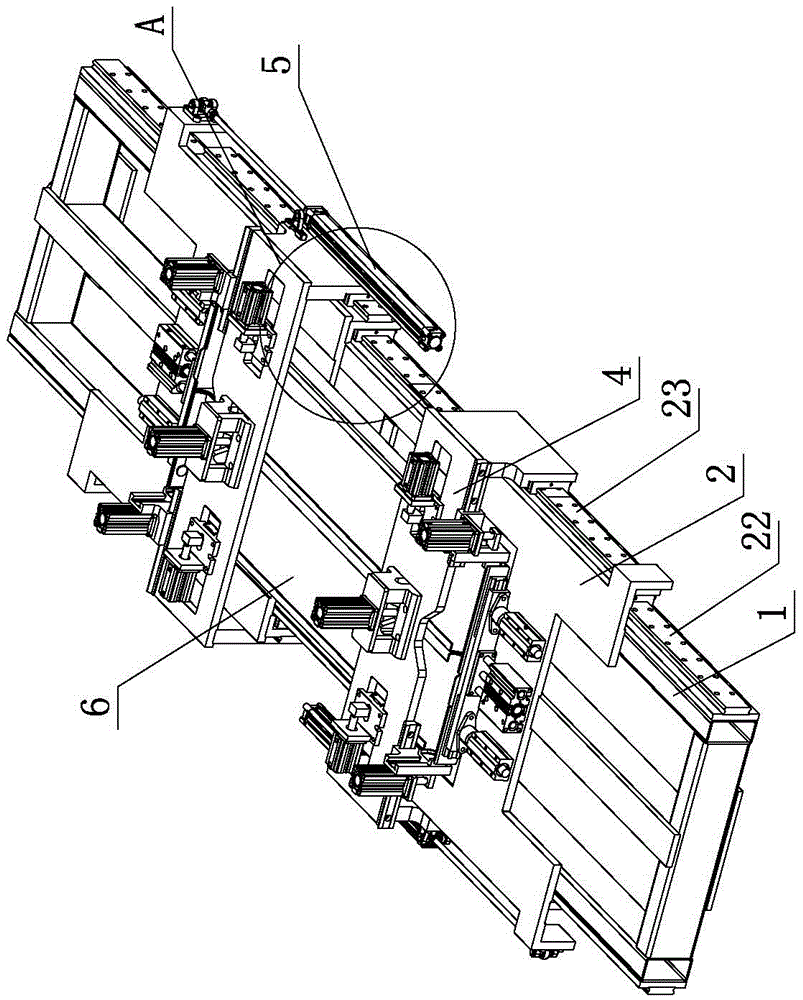

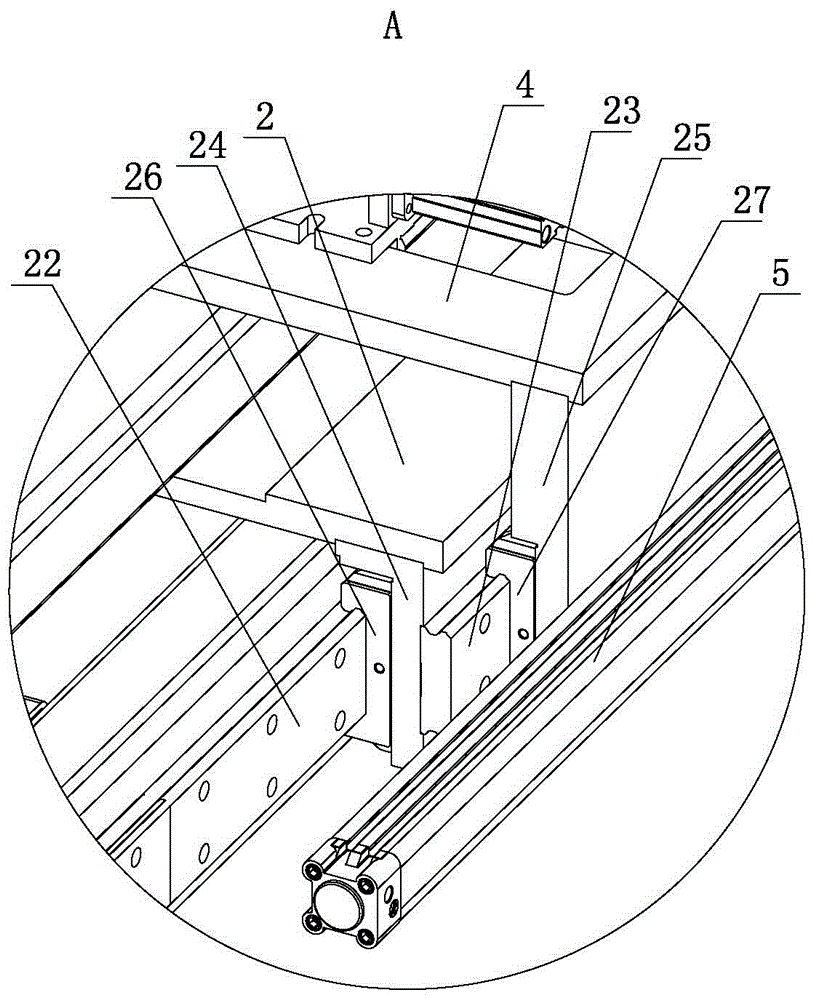

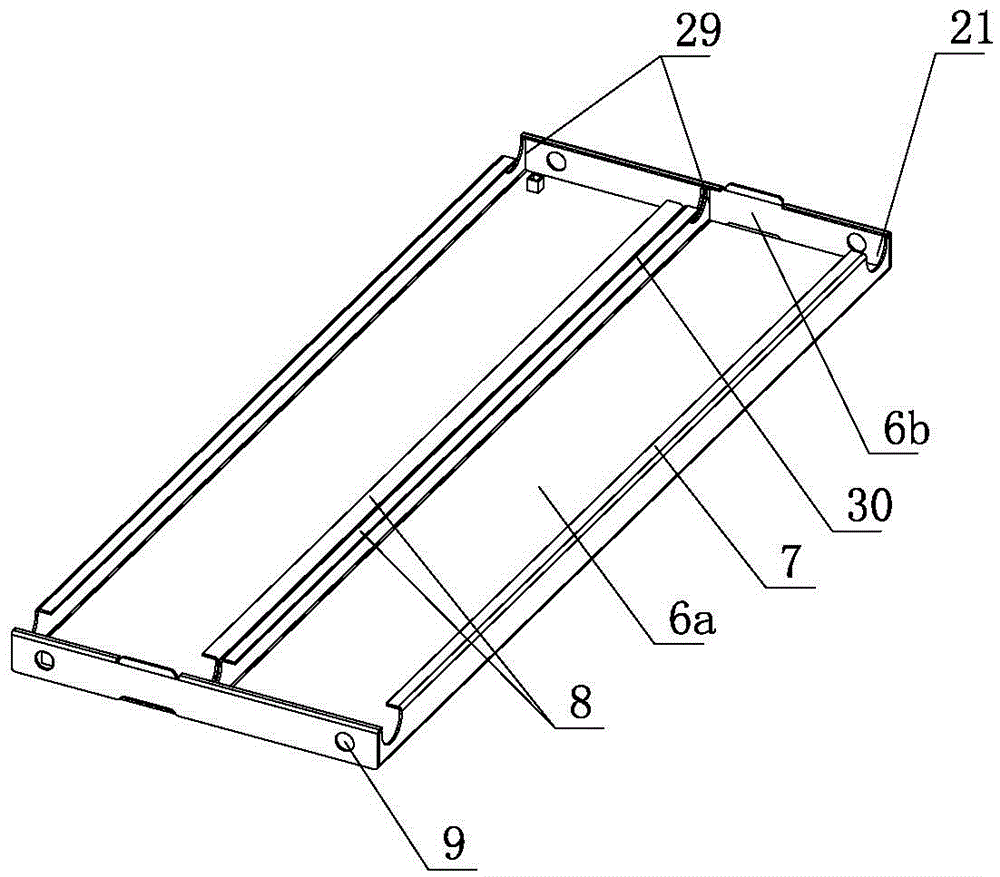

[0024] Such as Figure 1-11 As shown, it is a multi-board assembly and welding tool, including a cuboid base 1. Both ends of the base 1 are movably connected with a lower horizontal plate 2 that moves along the length direction of the base. The first cylinder 3, on the base 1, corresponding to each lower horizontal plate 2, is movably connected with an upper horizontal plate 4 that moves along the length direction of the base 1, and the base 1 is provided with a second cylinder 5 that is transmission-connected to the corresponding upper horizontal plate 4, The left and right sides of the base 1 are all provided with a guide rail-22, the left and right sides of the lower horizontal plate 4 are all provided with a slider connecting plate-24, and the slider connecting plate-24 is provided with a slider that is slidably connected with the corresponding guide rail-22 One 26; the slider connecting plate one 24 is provided with two guide rails 23, the left and right sides of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com