Profile bending machine

A bending machine and fuselage technology, applied in the field of profile bending machines, can solve problems such as troublesome operation, inability to pre-bend, large oil cylinder, etc., and achieve the effects of saving space, high precision, and small machine volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

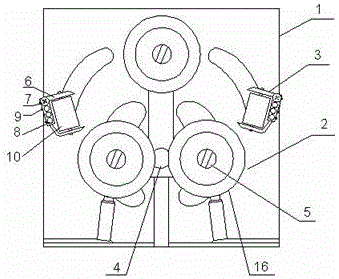

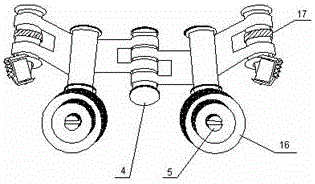

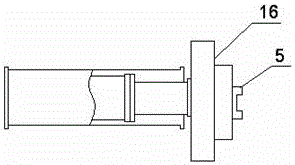

[0027] Such as Figure 1-Figure 3 As shown, the profile bending machine of the present invention includes a fuselage 1, a work roll device 2, an idler roller device 3 and a transmission system; the transmission system includes hydraulic motors and gears, and the transmission system is connected with the The working roll device 2 is connected with the idler roll device 3, and the working roll device 2 and the idler roll device 3 are driven to rotate respectively through the meshing of the gears; the working roll device 2 is divided into an upper roll and two left and right lower rolls, so The upper roller sleeve is fixed on the fuselage 1, and there is a central axis 4 parallel to the upper roller directly below the center of the upper roller, and the two ends of the central axis 4 are fixed on the fuselage 1. The two lower rollers are located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com