A flexible integral concrete spraying layer for roadway bolting and spraying support and its construction method

A construction method, the technology of concrete spraying layer, applied in the direction of tunnel, bolt installation, earthwork drilling and mining, etc., can solve the problems of increasing deformation rate of surrounding rock, loss of bearing capacity of bolt, deterioration of stability of surrounding rock, etc., reaching the limit of increase Amount of deformation, improved integrity and stability, improved flexibility and the effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

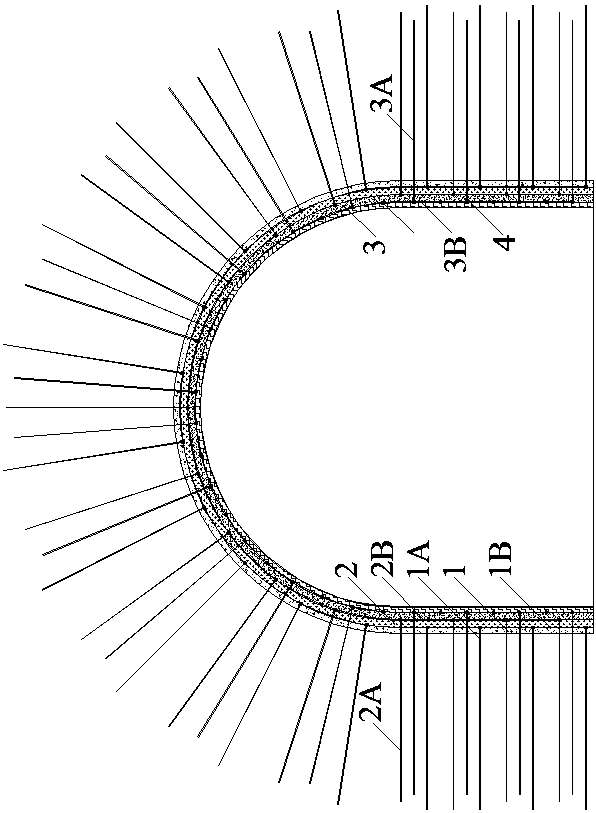

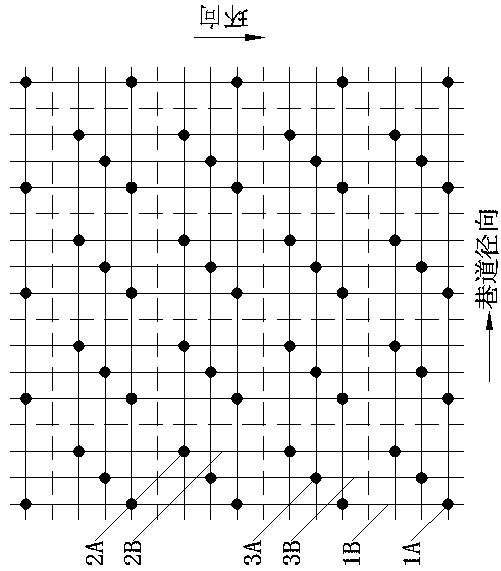

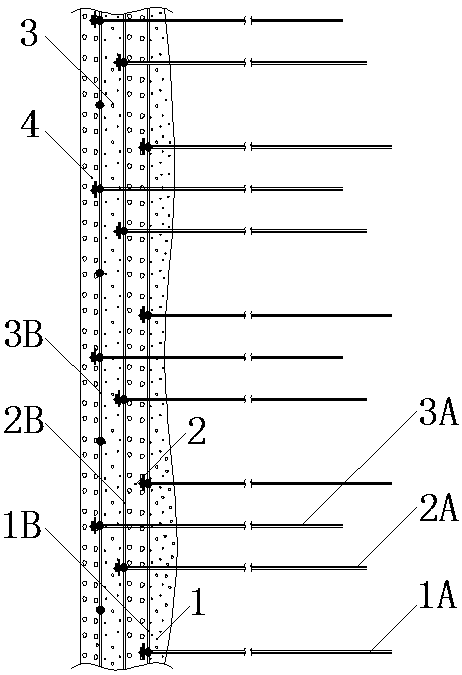

[0016] Such as Figure 1-3 As shown, a flexible integral concrete spraying layer for roadway anchoring and spraying support of the present invention includes the first layer of sprayed concrete 1, the second layer of sprayed concrete 2, the third layer of sprayed concrete 3 and the first layer of sprayed concrete sprayed on the surface of the roadway surrounding rock in sequence Four layers of shotcrete 4, a number of first anchor layers 1A, a number of second anchor layers 2A and a number of third anchor layers 3A are arranged in the deep coal seam around the roadway, and all the first anchor layers 1A are along the axis of the roadway The direction is evenly arranged side by side. Each row of the first anchor layer 1A includes several first anchor rods evenly arranged along the circumference of the roadway. The anchor tail ends of the first anchor rods are fixed with trays by tightening nuts. Shotcrete 1 is compacted and compacted, and two adjacent first anchor rods are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com