An automatic capping machine and its working method

A capping machine, automatic technology, applied in the direction of threaded bottle caps, etc., can solve the problems of over-tightening, slow capping speed, and untightened bottle caps, etc., to achieve the effect of convenient operation, easy clamping, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

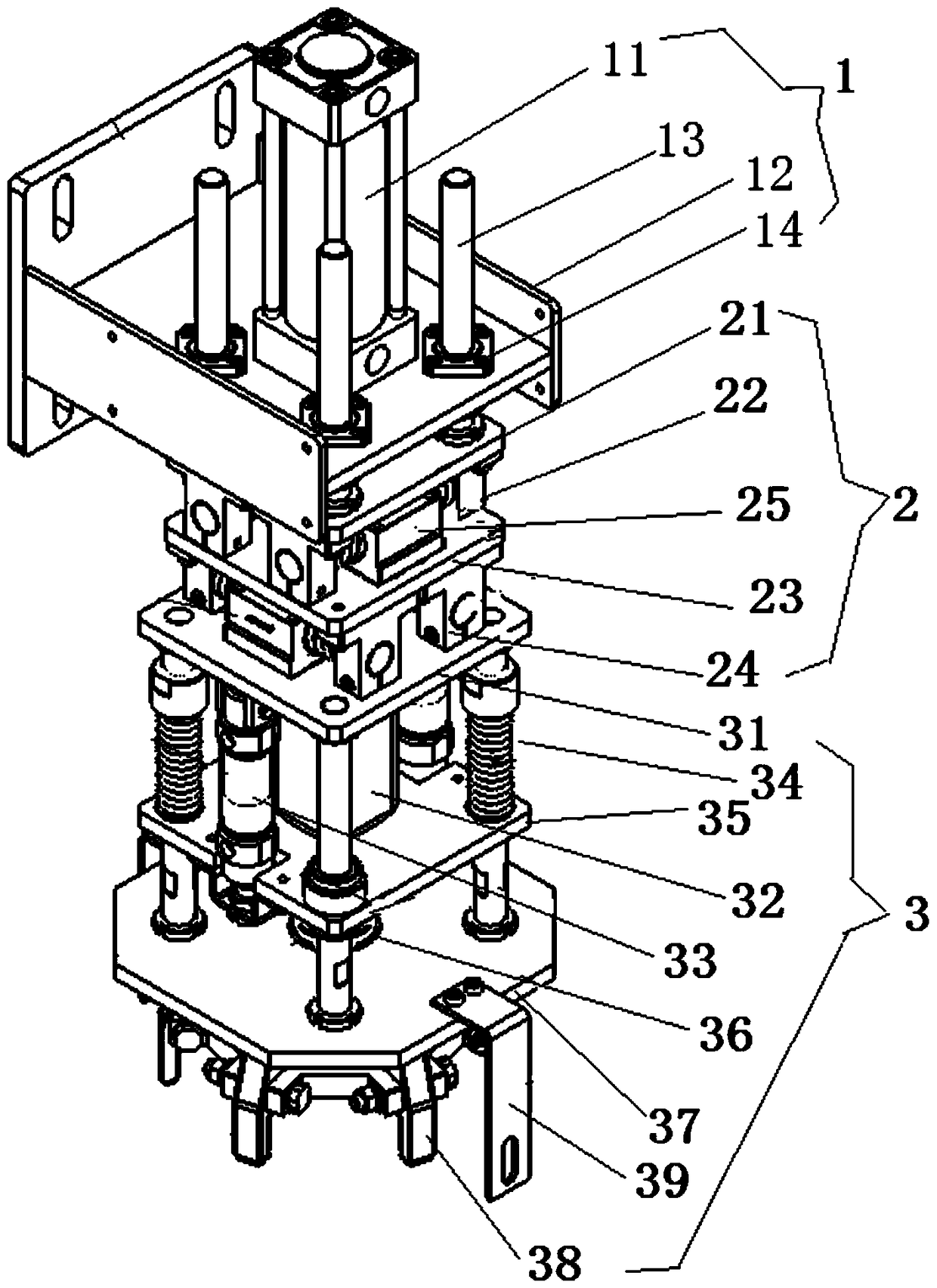

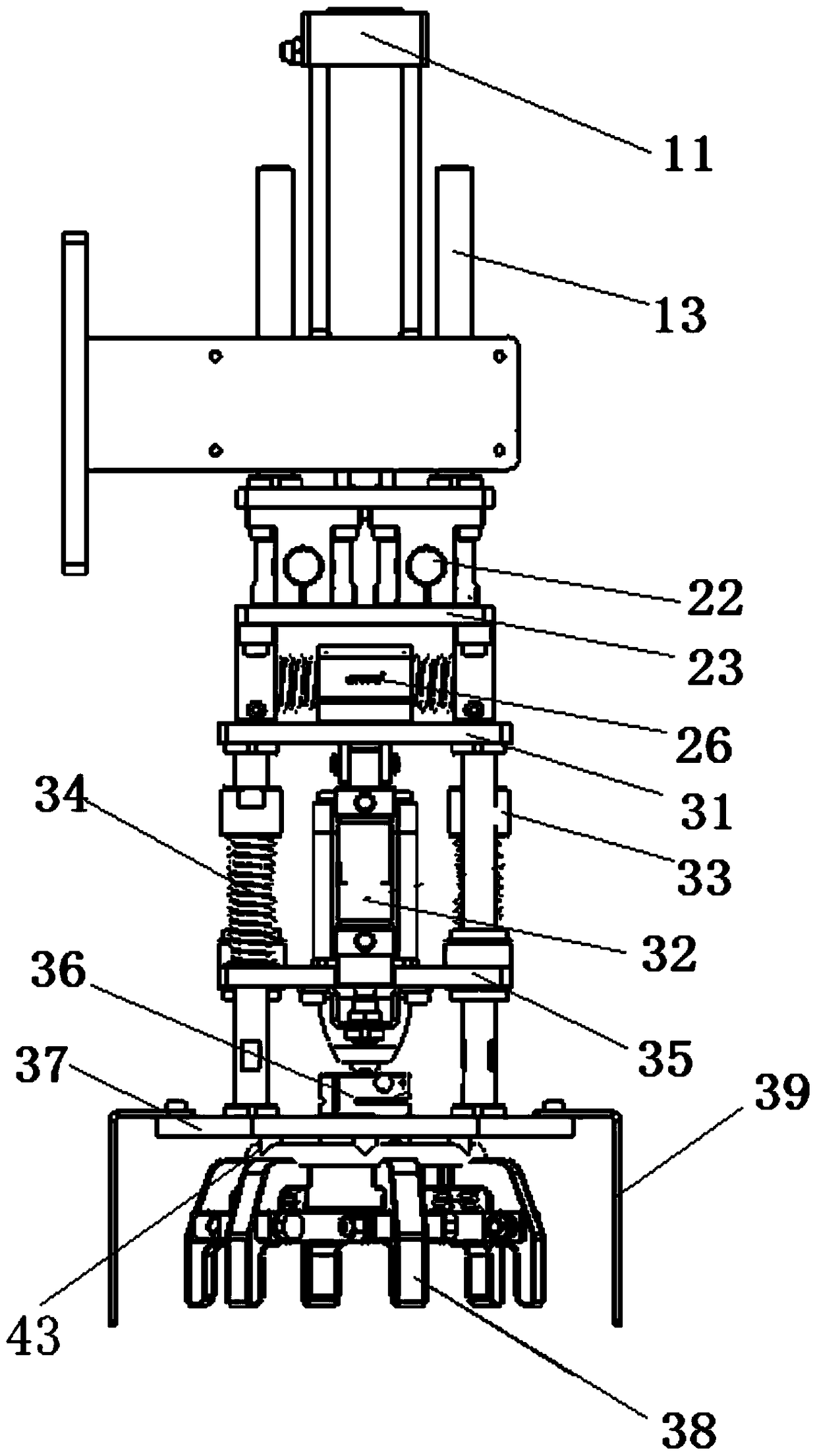

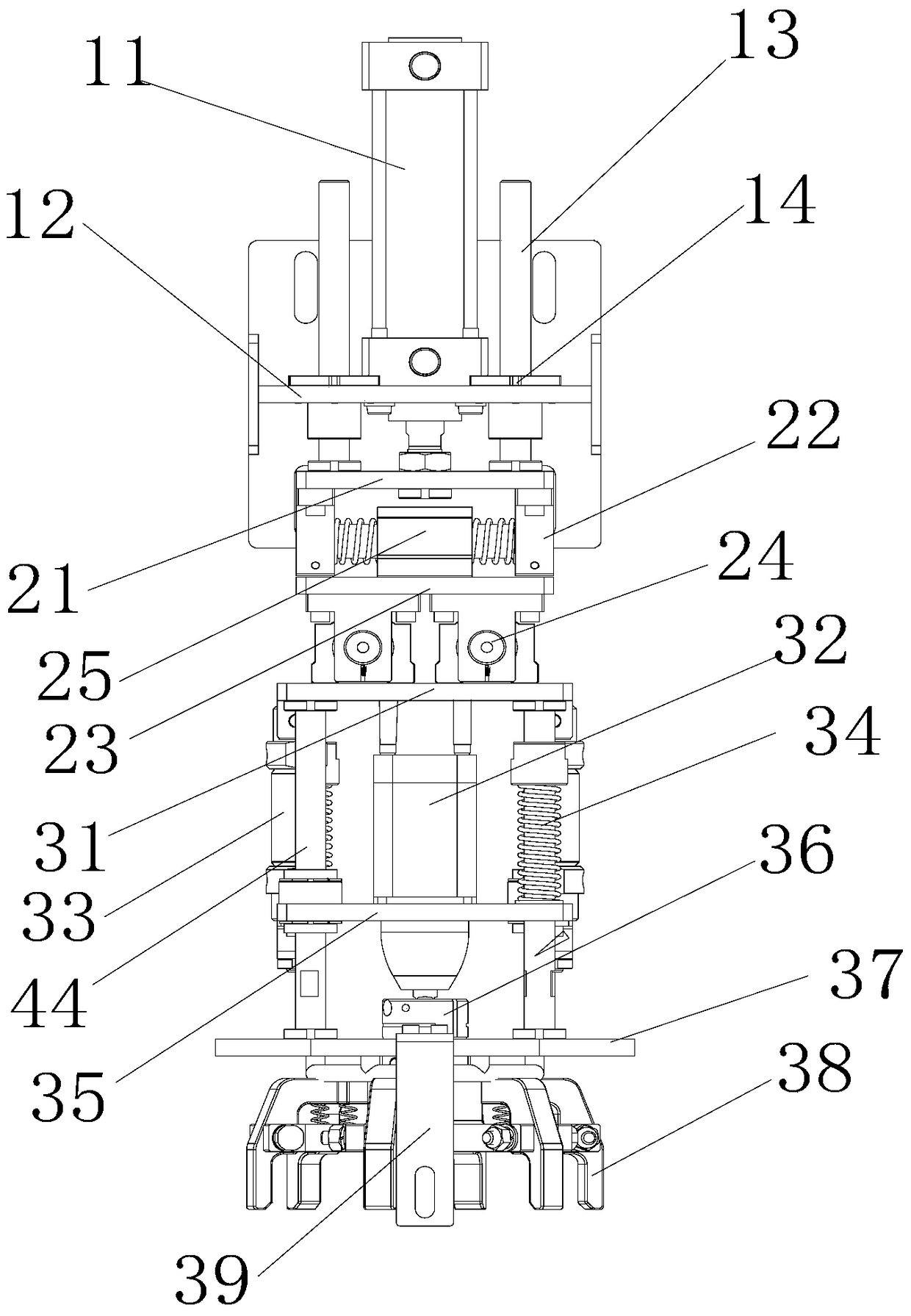

[0036] Example 1 as Figure 1 to Figure 6 As shown, the automatic capping machine of this embodiment includes a main machine, a lifting assembly 1 for the vertical displacement of the main machine arranged in sequence from top to bottom, a displacement assembly 2 for controlling the front and rear and left and right displacements of the main machine, and a displacement assembly 2 for controlling the automatic The capping machine takes the cap and the capping assembly 3 of the capping, the lifting assembly 1 and the displacement assembly 2 are connected through multiple sets of linear guide rails 13 and linear bearings 14, and the bottom of the displacement assembly 2 is fixedly connected with the top of the screwing assembly 3 .

[0037] Lifting assembly 1 comprises mounting frame 12 and lifting cylinder 11, and the center of mounting frame 12 is provided with through hole, and the output shaft of lifting cylinder 11 passes through hole and reciprocates; , the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com