Protective device used for pulling large workpieces to move in machining workshop

A technology for large workpieces and protective devices, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material handling, etc. The effect of collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

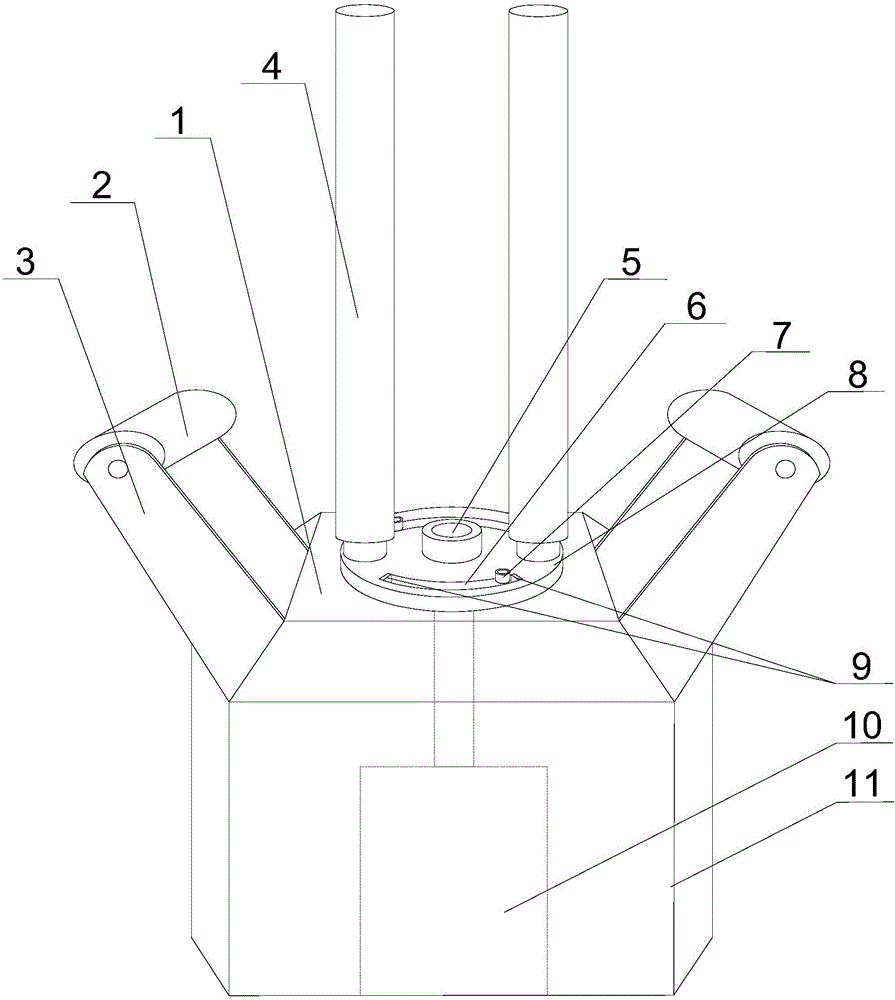

[0021] Such as figure 1 As shown, this embodiment includes a workbench and a mount 1 fixed on the workbench, brackets 3 are respectively fixed on both sides of the mount 1, and a roller 2 whose axis is perpendicular to the moving direction of the traction line is rotatably arranged on the On the bracket 3, a turntable 8 is arranged in the middle of the mounting seat 1 through the rotation of the central shaft 5, and two vertical adjustment rollers 4 are symmetrically arranged on the turntable 8 along its center of circle. An arc-shaped limiting groove 6, and two fixing holes are arranged symmetrically along its axis on the mounting base 1, and the end of the positioning rod 7 moves vertically through the limiting groove 6 and is connected with the fixing holes. At least two annular grooves are arranged on the regulating roller 4, and the regulating roller 4 is sleeved on the regulating roller 4, and a travel switch 9 which is rotatably arranged on the circular groove is includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com