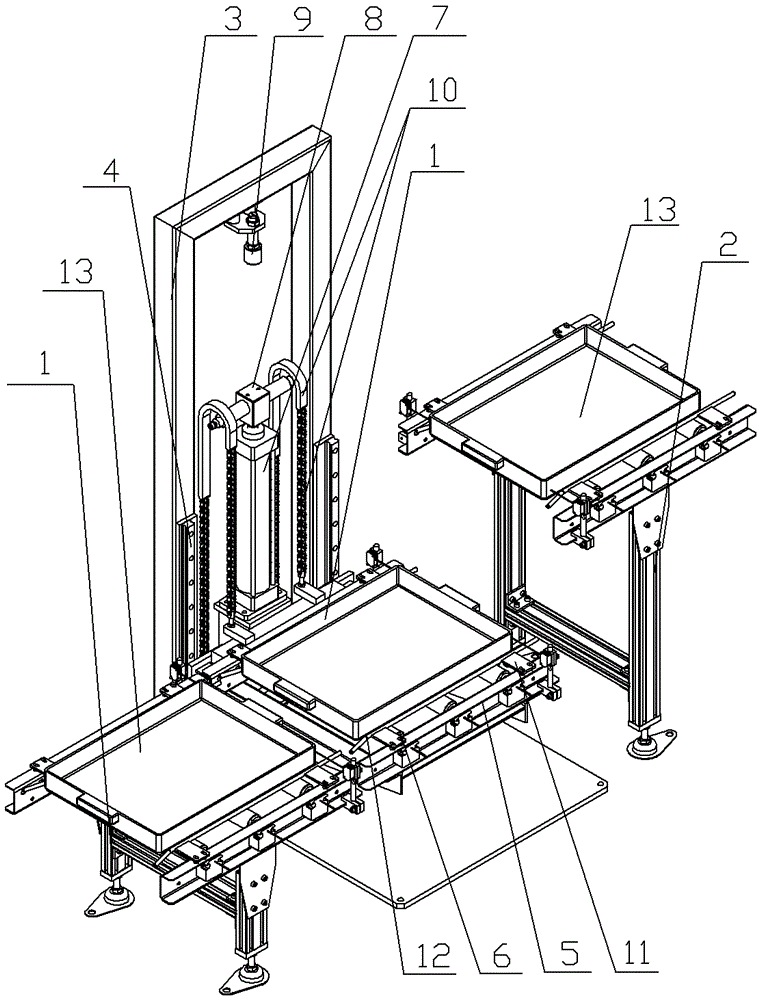

Tray lifting and conveying mechanism

A conveying mechanism and pallet lifting technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency and the conveying line is not in a plane, and achieve the effect of ensuring the conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] See figure 1 As shown, a pallet lifting and conveying mechanism includes a first conveying line 1 and a second conveying line 2, the height of the second conveying line 2 is higher than that of the first conveying line 1, and the distance between the first conveying line 1 and the second conveying line 2 A lifting mechanism is arranged between them, and the lifting mechanism includes an inverted U-shaped bracket 3. Linear guide rails 4 are installed on the two vertical bars of the inverted U-shaped bracket 3 respectively. Lifting roller frames 5 are installed on the linear guide rails 4 through sliders. A plurality of conveying rollers 6 are installed on the barrel frame 5, and the conveying rollers 6 are electric rollers, and limit stops 12 are installed on both sides of the conveying roller 6, and a longitudinal drive is installed between the two vertical bars of the inverted U-shaped bracket 3. Cylinder 7, the piston rod of longitudinal drive cylinder 7 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com