Rail vehicle coupler mounting device

A coupler installation, rail vehicle technology, applied in the direction of railway vehicle coupling accessories, transportation and packaging, railway car body parts, etc., can solve the problems of low labor efficiency, low reliability, harsh working environment, etc., and achieve convenient disassembly and installation , Guaranteed passability, ingeniously designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

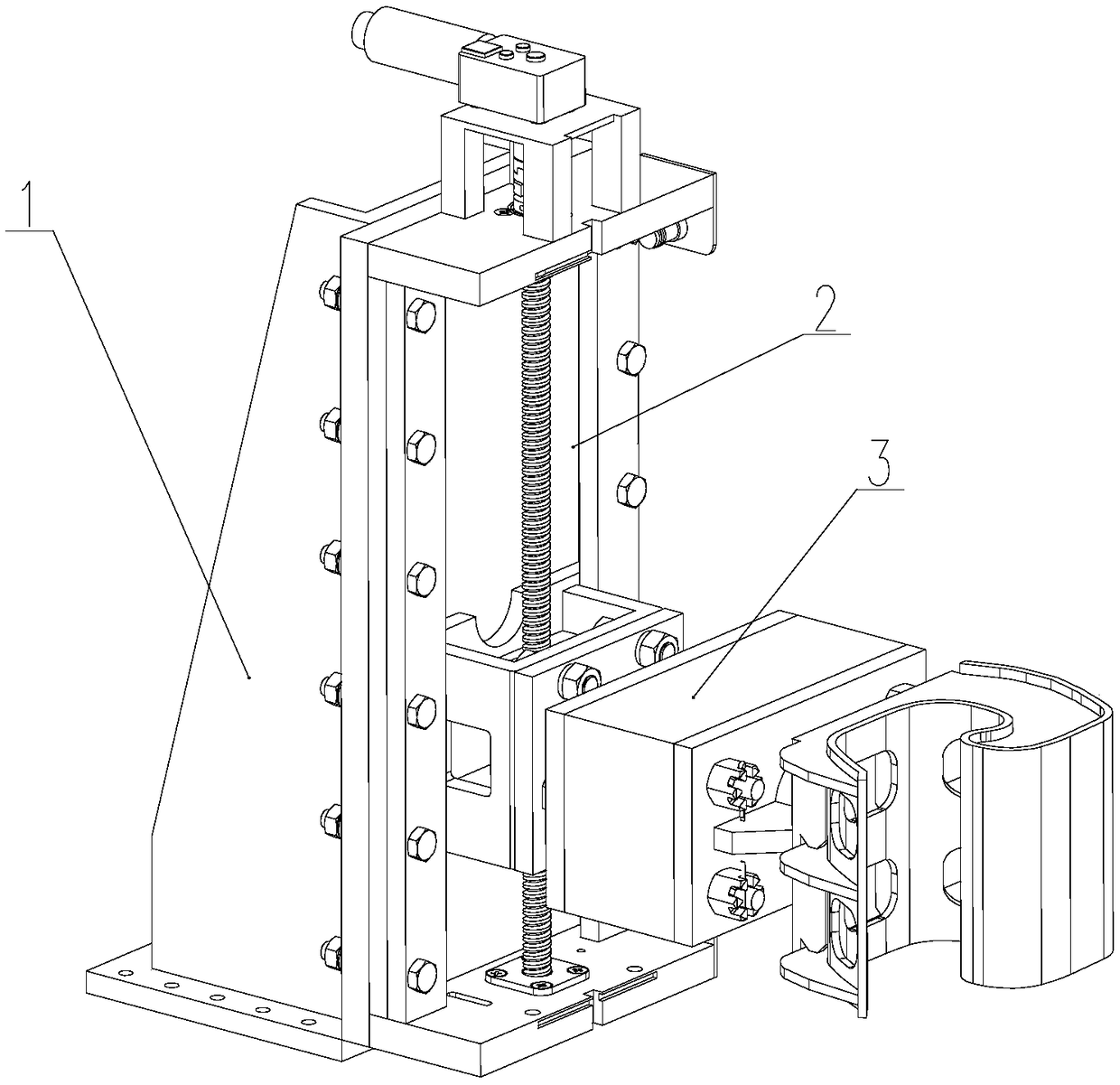

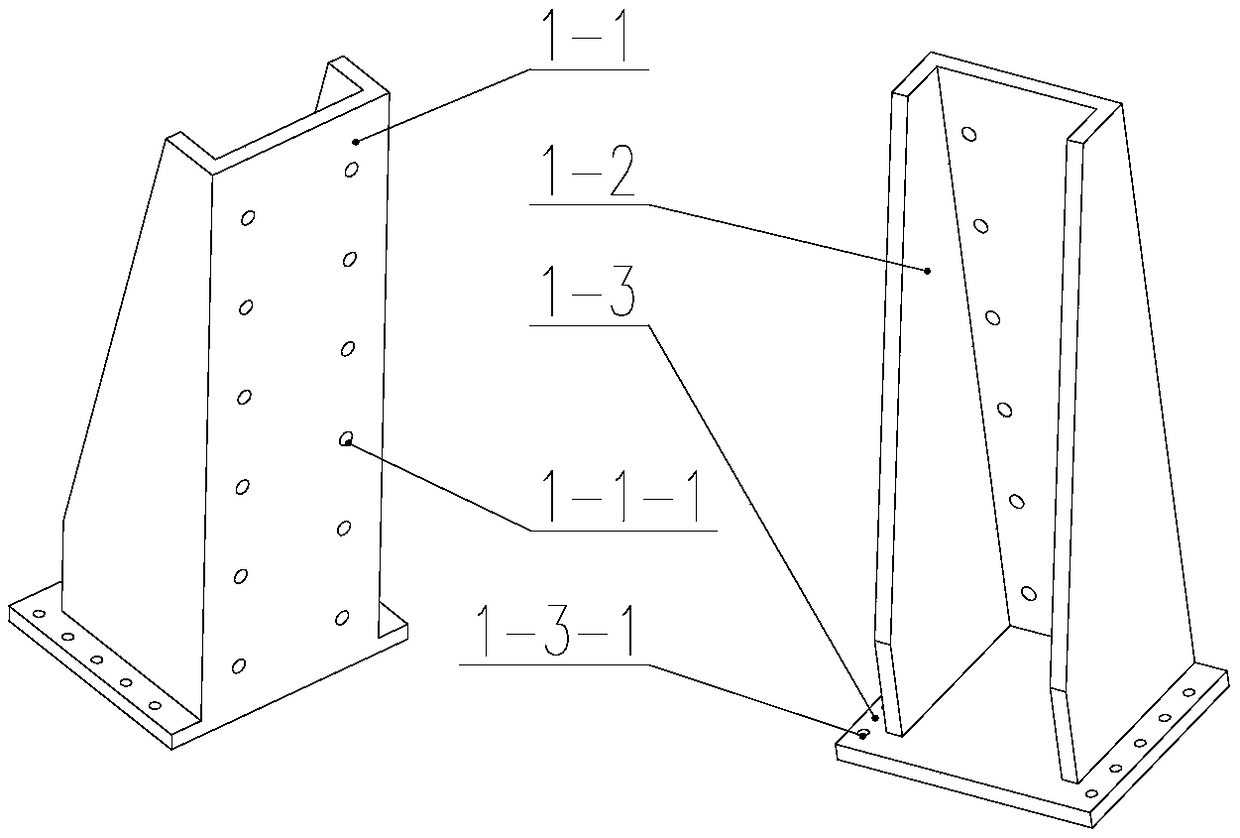

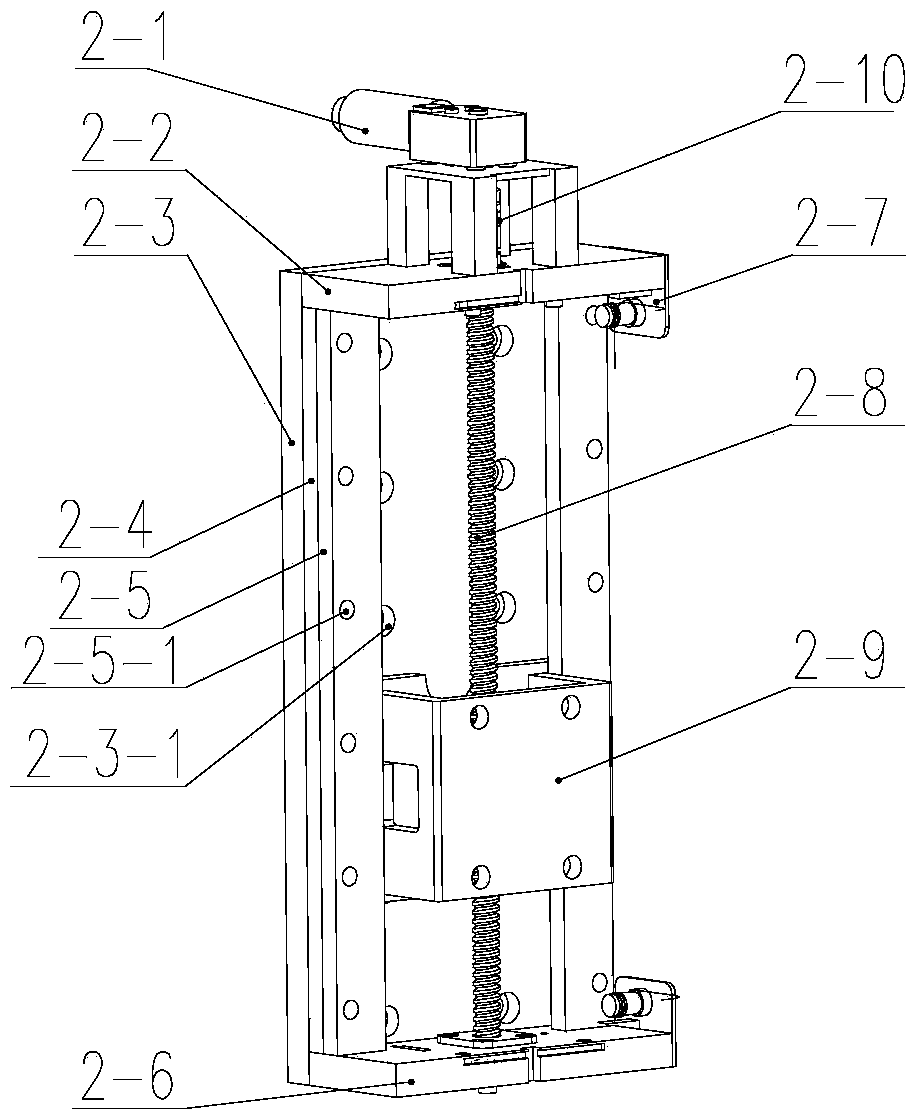

[0029] The rail vehicle coupler mounting device of the present embodiment has a structure such as figure 1 As shown, it is mainly composed of a fixing base 1, a lifting mechanism 2 and a buffer 3, the fixing base 1 is used for installing the lifting mechanism 2, and the lifting structure 2 is connected with the buffer 3. Wherein, the fixed seat 1 includes a first vertical plate 1-1, two rib plates 1-2 and a rectangular bottom plate 1-3, and the first vertical plate 1-1 and the two rib plates 1-2 are vertically arranged on the bottom plate 1. -3, and two ribs 1-2 are vertically fixedly connected to the left and right sides of the first vertical plate 1-1, and two groups of first installation holes 1 are formed on the first vertical plate 1-1 along its length direction -1-1, a group of second mounting holes 1-3-1 are respectively formed on both sides of the bottom plate 1-3, and a second bolt is provided in cooperation with the second mounting hole 1-3-1, through which the The ...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the buffer block 3-3 adopts a rubber part in the shape of a cuboid as a whole, without front and rear end plate structures, and the front end of the buffer block 3-3 passes through the front connecting rod 3-2. 1. The second connection plate 3-1 is connected with the first connection plate 2-9-3 of the buffer connection seat 2-9, and the rear end surface of the buffer block 3-3 is connected with the hook head 3 of different types through the rear connection rod 3-4 -8 connection, at the four corners of the buffer block 3-3, there are through holes through the front and rear ends of the buffer block 3-3 respectively, and a force guide rod 3-5 is arranged in the through hole, and the front end of the force guide rod 3-5 has a guiding force The rod cap 3-5-3, and the force guide rod cap 3-5-3 is in contact with the front end surface of the buffer block 3-3, the rear end of the force guide rod 3-5 has an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com