A friction manipulator

A technology of manipulators and friction wheels, which is applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of cumbersome operation and low efficiency, and achieve the effect of simple design mechanism, improved efficiency and reduced physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

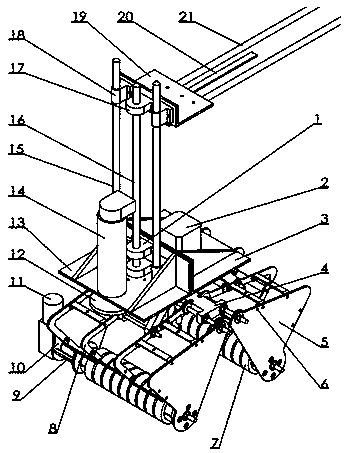

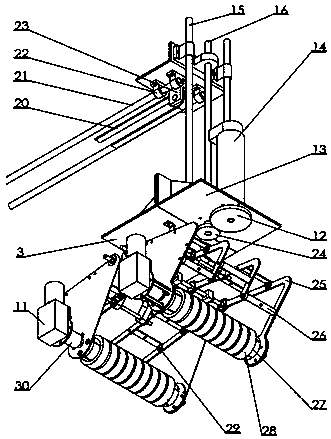

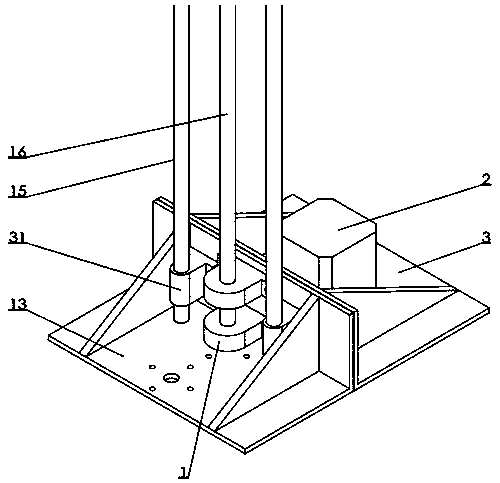

[0025] Embodiment 1: as Figure 1-9As shown, a friction manipulator includes a bearing seat 1, a motor I2, a fixed plate I3, a two-axis fixed piece 4, a baffle plate 5, a screw 6, a friction device 7, a connecting rod I8, a large gear 12, a fixed plate III13, and a motor Ⅲ14, guide rod Ⅰ15, screw rod Ⅰ16, screw nut Ⅰ17, guide rod connector 18, fixing plate Ⅳ19, belt 20, guide rod Ⅱ21, guide fixing seat 22, pulley fixing seat 23, pinion gear 24, connecting rod Ⅱ25, Connecting piece 26, connecting rod screw 29, guide rod I fixing seat 31, pulley 32, pulley shaft 33, fixing plate screw 34, major axis 35, nut 36, connecting rod connecting piece 37, short axis 38, fixing plate I connecting piece 39. Coupling Ⅱ40, bearing Ⅰ41, screw rod Ⅱ44, screw nut Ⅱ45; fixed plate Ⅰ3, fixed plate Ⅲ13 are connected by fixed plate screw 34, bearing seat 1 is installed on fixed plate Ⅲ13, motor Ⅰ2 is installed on fixed plate Ⅰ3 In the middle, the motor III14 is installed on the fixed plate III13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com