Smashing, drying and reutilization device of straw

A straw crushing and crushing device technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve problems such as pollution, low efficiency, and non-drying of straw, and achieve improved drying efficiency, high efficiency, and The effect of crushing particles with uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

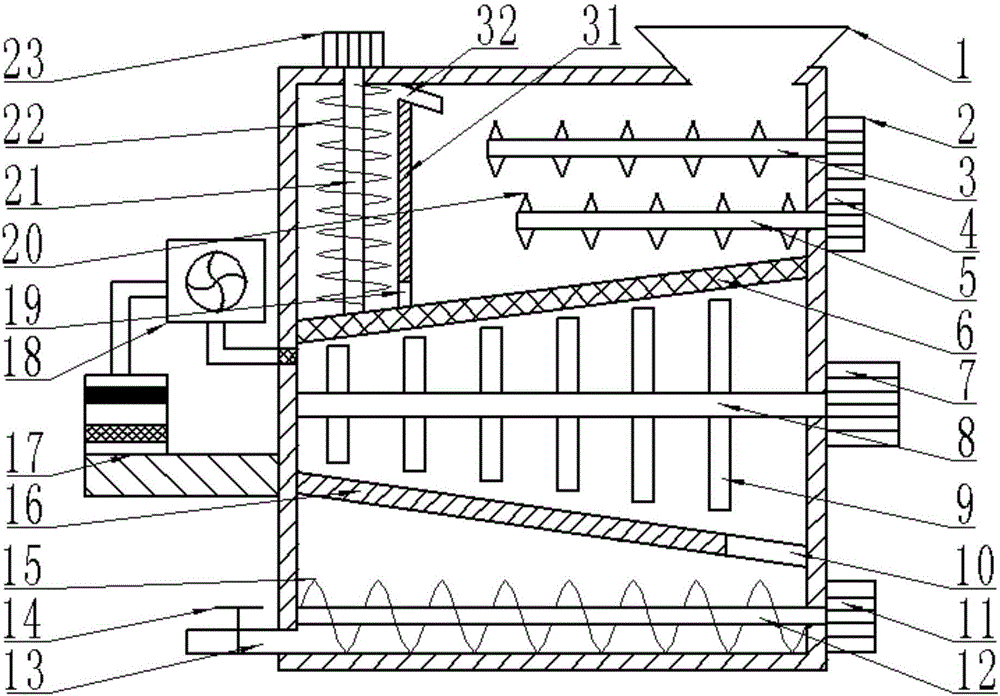

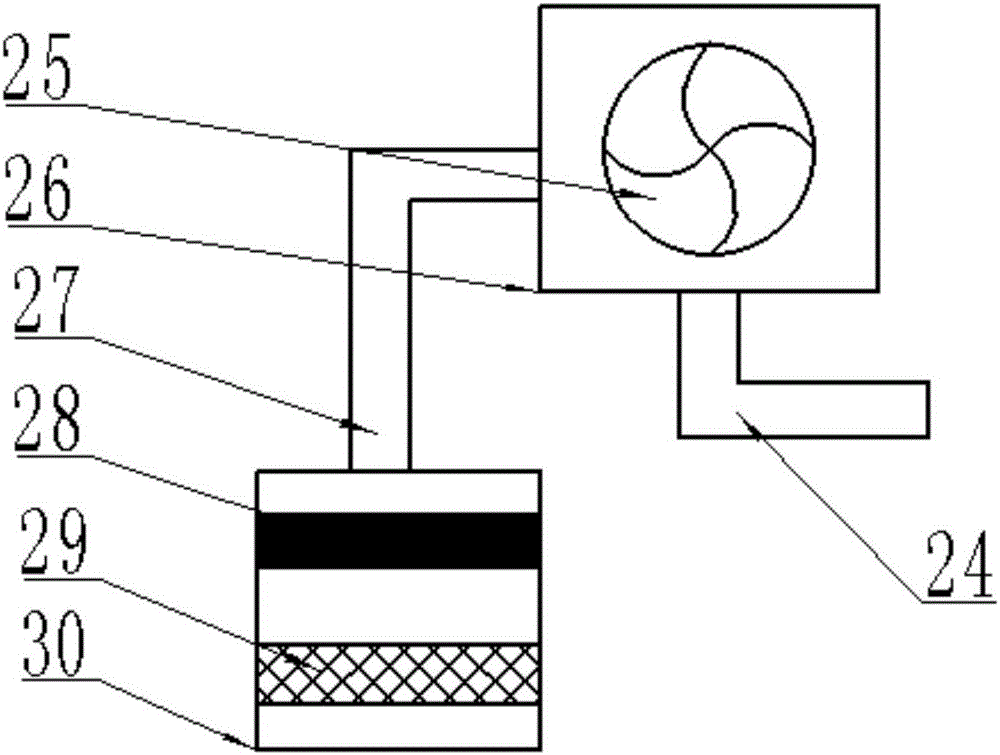

[0016] see Figure 1-2 , this embodiment provides a device for crushing, drying and reusing straw, including a feed hopper 1, a crushing device, a stirring device, a conveying device, a discharge pipe 13 and a drying device 18; the feed hopper 1 is arranged at the upper end of the box body On the right side, the feed hopper 1 is conical; the crushing device includes a first drive motor 2, a second drive motor 4 and a fifth drive motor 23; the first drive motor 2 is fixed on the right end wall of the casing, and the first The left end of the driving motor 2 is provided with a first rotating shaft 3; the first rotating shaft 3 runs through the box, and the first rotating shaft 3 is provided with a crushing blade 20; the crushing blades 20 are provided with several, symmetrically distributed on the first rotating shaft 3 ; The second drive motor 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com