Green plum and natto composition with gout treatment effect and preparation method thereof

The technology of a composition and an effective component, which is applied in the field of compositions for treating gout, can solve the problems that the curative effect needs to be further improved, and achieve the effect of optimal treatment of gout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

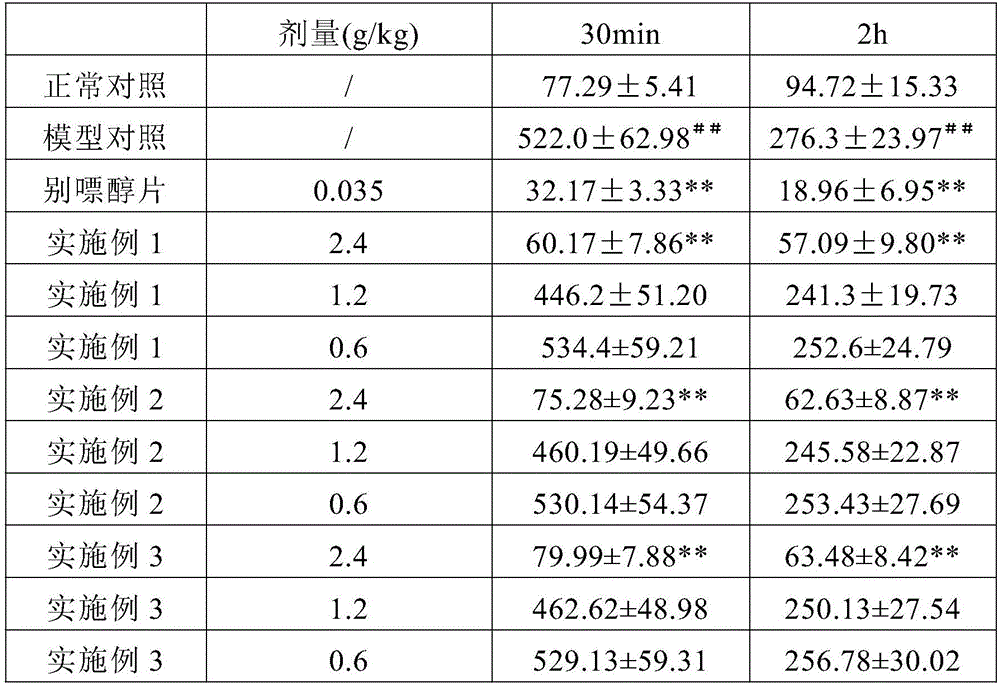

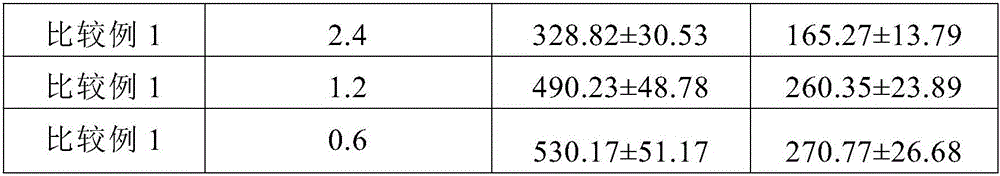

Examples

Embodiment 1

[0040] Embodiment 1: There is the composition (1) of treating gout effect

[0041] (1) Composition of raw materials: green plum extract, 220 parts by weight; natto powder, 1.6 parts by weight; grape skin extract, 1.4 parts by weight; hawthorn powder, 17.5 parts by weight; pomegranate powder, 7.5 parts by weight; lactose, 10 parts by weight; malt paste Essence, 114 parts by weight.

[0042] (2) Preparation steps:

[0043] Take the above raw materials and mix them evenly; add 85% ethanol solution as a wetting agent to make soft materials, sieve and granulate; wet granules are ventilated and dried at 50°C;

Embodiment 2

[0044] Embodiment 2: There is the composition (two) of treating gout effect

[0045] (1) Composition of raw materials: green plum extract, 200 parts by weight; natto powder, 2 parts by weight; grape skin extract, 2 parts by weight; hawthorn powder, 20 parts by weight; pomegranate powder, 10 parts by weight; lactose, 10 parts by weight; malt paste Essence, 107 parts by weight.

[0046] (2) Preparation steps:

[0047] Take the above raw materials and mix them evenly; add 85% ethanol solution as a wetting agent to make soft materials, sieve and granulate; wet granules are ventilated and dried at 50°C;

Embodiment 3

[0048] Embodiment 3: There is the composition (three) of treating gout effect

[0049] (1) Composition of raw materials: green plum extract, 200 parts by weight; natto powder, 1.5 parts by weight; 1 part by weight of grape skin extract; 16 parts by weight of hawthorn powder; 5.5 parts by weight of pomegranate powder; lactose, 10 parts by weight; malt paste Essence, 102 parts by weight.

[0050] (2) Preparation steps:

[0051] Take the above raw materials and mix them evenly; add 85% ethanol solution as a wetting agent to make soft materials, sieve and granulate; wet granules are ventilated and dried at 50°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com