Numerical predication method for radiation noise of flow-induced structure of multi-stage centrifugal pump

A radiated noise and numerical prediction technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of reducing costs, shortening the research and development cycle, only considering the vibration and radiation noise of the flow noise structure, and reducing the number of tests. , The effect of shortening the R&D cycle and avoiding information loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

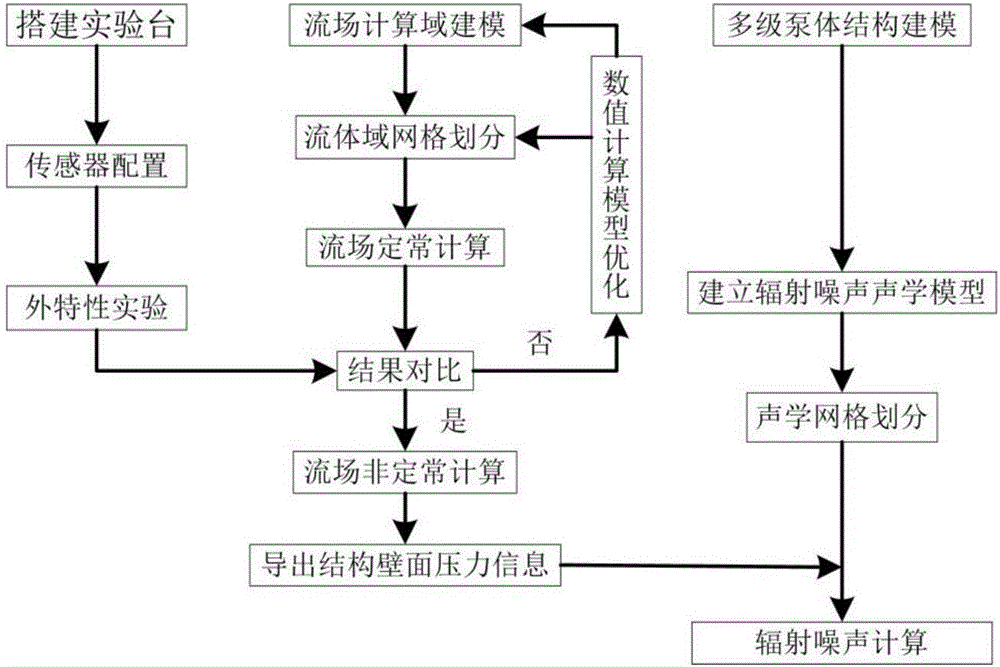

[0036] (1) A M220-7-12 multistage centrifugal pump is used as a model pump to carry out the numerical prediction of the flow-induced structural radiation noise of the multistage centrifugal pump. The whole prediction process is as follows: figure 1 shown. First, a multi-stage centrifugal pump test bench is built in a semi-anechoic chamber, such as Image 6 shown.

[0037] Secondly, the external characteristic experiment of multi-stage centrifugal pump is carried out to obtain the boundary conditions required for numerical calculation of the flow field, such as inlet pressure and outlet flow, and at the same time, the curve of the head, efficiency, and shaft power of the model pump with the flow rate is obtained;

[0038] (2) The boundary conditions obtained from the experiment of the external characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com